Wageningen University researcher, Sustainable Fisheries Partnership find value in ‘horizontal collaboration’ approach

Call it the “friends and family” strategy. It’s already paying off in efforts to recruit fish farmers into environmental-protection initiatives known as aquaculture improvement projects (AIPs).

The approach is a key finding in researcher Mariska Bottema’s study of how to reduce risks and improve environmental performance among small aquaculture operations.

Bottema, a researcher with the Environmental Policy Group at Wageningen University in the Netherlands, is working toward a Ph.D. in aquaculture governance. Her paper on sailing up AIPs, published Oct. 15 in the journal Aquaculture, is part of Wageningen’s four-year SUPERSEAS project — which stands for Supermarket supported area-based management and certification of aquaculture in Southeast Asia.

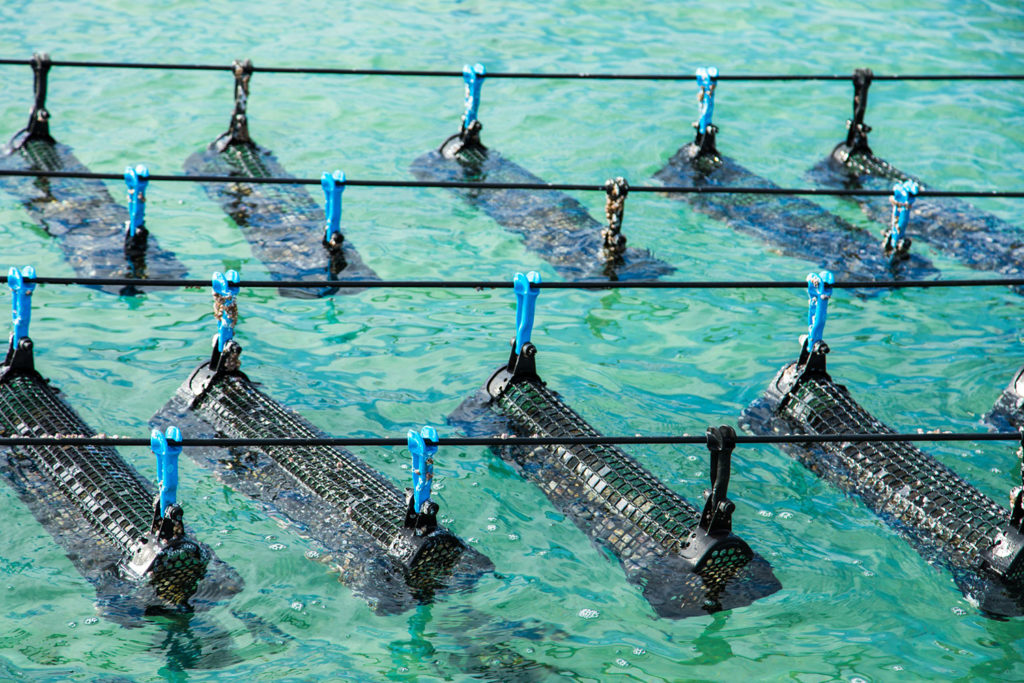

The environmental NGO Sustainable Fisheries Partnership (SFP) is one of the SUPERSEAS partners. With the goal of reducing the incidence of disease, SFP put the social network approach into practice about a year ago when it launched four new aquaculture improvement projects at shrimp farms in Indonesia and in the Thai provinces of Surat Thani and Chumphon.

Participating farmers can choose to use XpertSea’s XperCount disease-screening tool or any other farm management application. They enter information on weight and size of shrimp, plus data on water quality, feed, probiotic use and mortality. They can also send images. The farmer can then share summary information from his farm into an area-management tool that can then detect early signs of disease problems in a farm.

SFP started recruiting farmers for the project by working with local shrimp clubs that meet regularly to exchange information on best practices. SFP made sure it asked the club members if they had any other friends or family who they thought could be part of the project.

And it paid off.

“Farmers who are socially connected came and said, ‘We can get 40 farmers instantly in another province if you’re able to help us,” said Anton Immink, aquaculture director for SFP. “We started with two [groups] and added the third faster than we thought we’d be able to.”

Driving improvement

Bottema’s work is a step in understanding bigger-picture questions around achieving sustainability in the seafood supply: How to generate improvement among farms that are not certified — and are unlikely to be soon. Many small farms, for example, can’t afford the costs of certification.

What about the rest?

“How are we going to foster improvement among non-certified or non-certifiable seafood producers?” she said.

More than one-third of farmed seafood production is either certified by the Aquaculture Stewardship Council (1.33 percent) or rated “green” (32.79 percent) or yellow (1.1 percent) by Monterey Bay Aquarium Seafood Watch — two of the members of the Seafood Certification & Ratings Collaboration. (The other members: Fair Trade USA, Marine Stewardship Council and SFP.)

The Seafood Certification & Ratings Collaboration published “Sustainable Seafood: A Global Benchmark” in June 2018.

“If you’re asking the supply chain how and where to make a change it comes back down to individual farms,” Immink said, “but we’re trying to address these issues of scale. We engage groups of producers. So, then we need to find mechanisms to engage those groups.”To drive improvement, explains Immink, SFP wants to identify the best ways to scale up and engage groups of farmers in a zone or region.

Improvement means reducing disease — also one way to manage risk and a success tied to economic and environmental benefits. “Disease is the No. 1 issue that impacts the aquaculture industry, but also [we do this] to improve environmental quality,” said Immink.

“For us, particularly, that’s water quality, because essentially it doesn’t matter whether you’re farming in a cage in the ocean or a shrimp farmer in Thailand,” said Immink, “your farm is connected to your neighbor’s one way or another through the water you share — the water you take into your farm or the water that comes from your farm.”

Organization models

But how to effectively organize farms into an improvement project? You could use local, county boundaries or group farms by the water bodies they use.

Better: Understand the existing cooperative relationships among farmers to solve their problems and reduce their risk.

“It’s important to understand the social networks within which farmers are already managing production risks,” said Bottema. “Farmers are already talking with other farmers who are perhaps trusted family and friends about disease problems and other production risks. In some cases, they are also helping each other address or respond to these risks. For example, farmers may support each other in recovering from a flood or typhoon.”

The idea of using farmers’ existing social networks to drive improvement might seem basic. After all, it’s the same idea Facebook uses to grow networks. Yet, it’s easy to overlook.

Bottema looked at two case studies of aquaculture improvement projects.

In April and May 2017, Bottema interviewed 48 people at the two study sites. In both, she found farmers were working together — termed “horizontal collaboration” — outside of the AIP to manage their production risks.

“If an external actor comes in and organizes farmers in a way that’s different from how farmers have organized themselves,” said Bottema, “there’s a mismatch there, which may make it more difficult to induce collaboration between farmers and encourage shared environmental risk management. It’s important to understand existing social networks.”

Fishery improvement projects typically follow a bottom-up or top-down model, depending on whether a buyer or NGO is driving the project. Buyers use the power of price and market access to leverage improvement in a “top-down” project. NGOs often drive a bottom-up project, with the purpose of improvement being a competitive advantage for the fishery to gain new markets and improve prices.

‘Good uptake’

Selva Shrimp, one of the studied cases, refers to black tiger shrimp (Penaeus monodon) grown with zero-inputs in a mangrove forest ecosystem in Kien Vang forest in the Ngoc Hien district in Ca Mau, at the southern tip of Vietnam. Monterey Bay Aquarium rates the Selva Shrimp “silvoculture” method as a best choice/green-rated product.

According to a video on the Selva Shrimp website, since the shrimp grow in their natural environment, the mangrove ecosystem naturally provides food, and no antibiotics are used.

Selva Shrimp has a “top-down basic” organizational model because it’s buyer-driven. Minh Phu Seafood Corp. — Vietnam’s largest seafood processor — is one of three partners, with Blueyou Consulting and the Department of Agriculture and Rural Development.

Blueyou, which financed the project between June 2013 and December 2016, developed the Selva shrimp standard, which calls for operating the farms with a minimum mangrove coverage of 40 percent. In one sub-area of the project, Blueyou trained 400 participating farms that receive a price premium from the market and an environmental services fee for mangrove coverage from the government. There are about 3,000 Selva Shrimp-certified farms, and about the same number of families that work the farm and rely on its income. With an average family of three to four people, the income generated by raising Selva Shrimp sustains between 9,000 and 12,000 people, according to Jonas Walker, sustainable seafood consultant at Blueyou Consulting in Zurich, Switzerland.

In 2011, the Sustainable Fisheries Partnership initiated the Hainan Tilapia AIP in China with a goal of improving tilapia production quality through a Code of Good Practices. SFP had studied Chinese tilapia production, analyzing the supply chain and assessing disease risk and environmental impact of tilapia farming, according to Bottema’s paper. SFP recognized that since 95 percent of Hainan’s tilapia is exported to the United States and Europe, a market-driven improvement effort could work.

SFP helped create the Hainan Tilapia Sustainability Alliance, representing 90 farmers, and nine companies, including one U.S. buyer. The zone management approach aimed to address area-level production risks including effluent discharged from the farms and escaped tilapia.

The alliance, according to the paper, was successful at improving communication and relationships, and giving a voice to the industry. It seems to have had a stabilizing effect on a sector that had experienced price volatility following disease outbreaks and labor strife in the feed sector.

It’s important to understand existing social networks.

But it struggled to get farmers to work together within the AIP.

“However,” Bottema wrote, “as seen in Ca Mau, farmers in Hainan did collaborate with neighbors, relatives and friends outside the AIP to manage area-level production risk and market risk. They manage area-level production risk through building and maintaining canals and providing mutual assistance after weather events like storms and floods and manage market risk by collectively bargaining prices with processing companies and collectively buying feed and fingerlings.”

Her study affirmed others that farmers working together — termed “horizontal collaboration” — is critical to manage production risks beyond the boundaries of an individual farm. In both cases, farmers were already collaborating with family and friends to manage production and reduce local risks. Both projects, Selva Shrimp and Hainan Tilapia, struggled to induce horizontal cooperation within the goals of the AIP.

The problem, Bottema explained in the paper, is a mismatch that limits how effective area-level risk management can be institutionalized.

The technical focus for the new AIPs in Thailand and Indonesia, Immink explained, remains getting as many farmers as possible along two or three rivers to participate. But through the farmers’ existing networks, recruiting farmers from different rivers increases overall levels of participation in the project, but can dilute the river-focused effort in the short term, said Immink.

Now, those 120 farmers in Thailand are taking samples, bringing samples to diagnose, and improving their practices. Immink expects numbers will grow this year to 150 in Thailand and about 100 in Indonesia.

“That’s good uptake,” said Immink.

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lisa Duchene

Lisa Duchene has reported on the marine environment since 1993. She is a business-environment writer, essayist and communications consultant in central Pennsylvania.

Related Posts

Responsibility

Early-warning pilot project in Thailand aims to reduce risk of shrimp disease

A group of NGOs and businesses is developing tools and interfaces aimed at helping farmers reduce disease outbreaks both individually and at the area level.

Responsibility

Aquaculture certification steers to zone management

Zone management is an emerging field of interest among industry stakeholders. Experts say it will aid in controlling diseases and in determining carrying capacities. We take a closer look at the management tool’s potential.

Responsibility

Advancing the ecosystem services of aquaculture

The Nature Conservancy was inactive in aquaculture until new program leader Robert Jones joined. His focus is on the positive outcomes of responsible aquaculture.

Innovation & Investment

Is Africa a ‘new Asia’ for aquaculture?

Now is the time for investment in efficiency improvements, better genetics, health management and more competition and innovation in the feed sector. Let's not perpetuate the myth that just a little more investment in some technical solutions will solve the problems in Africa.