University research: Nutritional value of pond-produced zooplankton can be enhanced

Presently, almost 100 percent of the fingerlings of sunshine bass, a cross of female white bass with male striped bass, are seasonally produced in ponds. However, year-round production of sunshine bass of uniform size and enhanced quality would better serve markets throughout the year. The development of tank culture techniques can provide a means to do this.

Tank culture allows better control of temperature, lighting, water chemistry, live food populations, and nutrition; reduction in water use; and easier determination of fish health and survival. Tank culture can also be done regardless of climate and weather conditions. However, survival differences between pond and tank culture of sunshine bass fingerlings must be overcome to make tank culture feasible and profitable.

Thanks to improved pond management practices developed by an USDA Agricultural Research Service scientist in Stuttgart, Arkansas, USA, fry survival in ponds to harvest as fingerlings at 35 to 45 days post-hatch has risen from a variable 10 percent to a fairly stable 35 percent average within the past 10 years. For tank culture of sunshine bass, published reports and anecdotal information suggest that survival to 45 days is usually less than 10 percent.

Zooplankton management

Sunshine bass fry have tiny mouths and require initial live foods that are very small, typically rotifers. The growth of the fry must match increases in the size of the zooplankton they eat.

Proper pond fertilization techniques develop a zooplankton community dominated by high concentrations of rotifers that give way to a community dominated by larger copepod and cladoceran zooplankton. The trick is to stock 5-day-old fry into ponds just as the rotifers begin an exponential increase but before the copepods, which may eat the larvae, appear.

Tank culture mirrors pond culture. First, rotifers are fed, which greatly increases the difficulty because algae culture is also required to provide feed for the rotifers. Then the fry are converted to eating artemia nauplii before being trained to eat artificial feed.

The high costs of live food and the need for specially trained personnel to operate culture systems are the primary reasons sunshine bass producers do not rely on tank-cultured fingerlings to supply growout production. However, the private and public sectors are now conducting research on cost-effective methods to produce sunshine bass fingerlings in tanks.

The first sunshine bass fingerling culture in tanks was done at the HKD-Stuttgart National Aquaculture Research Center (HKD-SNARC) with freshwater rotifers. The fingerlings were converted to eating salmon starter meal by 26 days post-hatch. A report from the South Carolina Department of Natural Resources indicated that feeding brackish water rotifers for about eight days, then artemia nauplii followed by microencapsulated feed produced larger fish by 26 days.

New approach

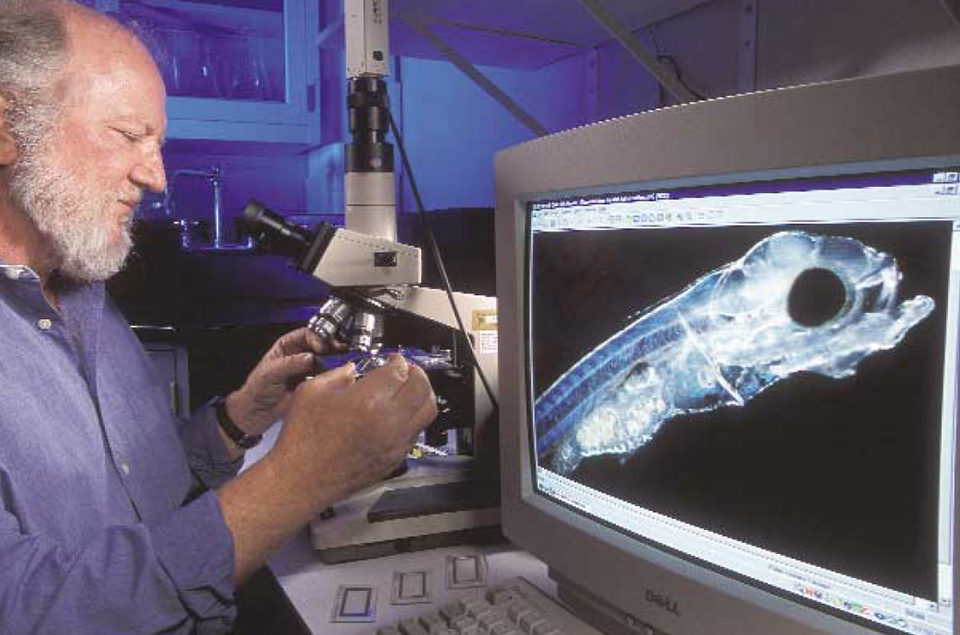

A novel approach in which rotifers and other zooplankton are harvested from specially prepared ponds with a rotating drum filter was used at HKD-SNARC to produce a crop of sunshine bass fingerlings. Research at Southern Illinois University has shown the nutritional value of pond-produced zooplankton can be enhanced by using the proper types of fertilizers, and University of Arkansas at Pine Bluff research reported that the nutritional levels of harvested zooplankton were further enhanced by enrichment with highly unsaturated fatty acids.

By harvesting zooplankton from a partitioned aquaculture system, one commercial sunshine bass producer has reduced the cost of tank-cultured fingerlings to approximately that of pond-produced fish. However, year-round production from such systems would require heating and probable enclosure by a greenhouse during the winter.

Rotifer culture

Several developments have reduced the costs and risks of providing live rotifers to sunshine bass fry. Instead of depending on unstable live algae cultures that require additional space and cost, producers can now purchase highly concentrated, refrigerated containers of microalgae, principally Nannochloropsis, to supply food to rotifer cultures.

A high-density, continuous rotifer culture system with concentrations routinely exceeding 1,500 rotifers per milligram was developed by USDA Agricultural Research Service scientists. A similar system is available commercially.

These systems’ method utilizes oxygen injection and filters to remove fecal contamination – procedures discovered by Japanese researchers. Sodium hydroxymethanesulfonate products are used to eliminate ammonia concentrations that limit rotifer numbers. Sodium bicarbonate use counteracts the decreased pH brought on by carbon dioxide from high respiration levels.

Daily harvests of 30 to 40 percent maintain the culture at its maximum sustainable yield level and help prevent or control ciliate contamination. Nutrient enrichment is easily done by mixing microalgae species or including enrichment products in the culture media. In the future, probiotics may be used to minimize culture contamination by undesirable bacteria.

Fingerling trial

Optimum stocking levels, feed concentrations, temperatures, light levels, and other culture variables have not been fully determined for sunshine bass. However, the following procedure was recently used at HKD-SNARC to produce the largest fingerlings yet reported at 26 days post-hatch.

Four-day-old fry were stocked at 10 rates between 30 and 120 fry per liter into dark blue 100-liter, semi-square plas-tic tanks that contained 8 ppt brackish water. Initially 18 degrees-C, water temperature was maintained at 26 degrees-C after the first day. Sodium hydroxymethanesulfonate was used to minimize ammonia levels. Three-fourths of the tank water was changed daily until 12 days, when fresh water was introduced to provide six tank turnovers daily.

Tanks were lit by 1,000-lumen fluorescent light at the water surface for 12 hours each day. For days 5 to 11, fry were fed rotifers raised with Nannochloropsis and a commercial larval supplement four times daily at 15 rotifers per milligram. Starting seven days post-hatch, artemia nauplii less than 24 hours old were fed at 4 per milliliter once per day. That rate was incrementally increased to five daily feedings by 20 days. Six grams of salmon starter meal were presented daily via a belt feeder 20 to 22 days post-hatch, with 8 grams offered 23 to 25 days post-hatch.

Results

The fish were harvested 26 days posthatch, the time previous experiments showed the fry were feed trained. Previously, harvested fish were enumerated with a commercial fry counter, but the smallest fish in this experiment were too large for the counter. Their weights ranged 0.04 to 0.33 grams and averaged 0.12 grams overall, while survival rates averaged 36 percent.

As the fish grew larger, their behavior changed from a generally random or current-directed orientation with darting movements near the top of the tank to schooling behavior with constant swimming around the bottom half of the tanks. This appeared to be a size-related change that was first noted in the tanks with the largest fish at 18 days. Although frequently observed during previous experiments, cannibalism was seldom noted during this study.

The propensity for cannibalism in sunshine bass fry, which usually starts 18 to 22 days post-hatch, can cause drastic reductions in survival. Feeding at high rates tends to reduce cannibalism. However, once cannibalism starts, the most effective means of controlling the behavior is probably isolation of the larger fish by grading. The development of a means for effectively grading these fish with minimal stress will be an important contribution toward increasing the survival of fingerling sunshine bass and making their culture economically feasible.

Research needs

Further advances in the cost-effective culture of sunshine bass fry to fingerlings depend on fully determining optimum culture methods while minimizing all production costs. Research needs include a better understanding of culture temperatures, feeding rates, light intensity, photoperiod and nutrient requirements. Genetic manipulation to increase mouth size and preclude the need for rotifers to reduce time to weaning to artificial feeds may also be attempted in the near future.

(Editor’s Note: This article was originally published in the August 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Gerald M. Ludwig, Ph.D.

USDA Agricultural Research Service

HKD-Stuttgart National Aquaculture Research Center

2955 Highway 130 East

Stuttgart, Arkansas 72160 USA[118,111,103,46,97,100,115,117,46,115,114,97,46,97,112,115,64,103,105,119,100,117,108,103]

Tagged With

Related Posts

Health & Welfare

Egg saprolegniasis in a commercial sunshine bass hatchery

Fungal growth on the eggs caused by the water mold Saprolegnia spp. is an obstacle to the larval production of sunshine bass. This study confirmed that copper sulfate can be an economical and valuable resource in hatchery management for the control of saprolegniasis on sunshine bass eggs in McDonald jars.

Responsibility

A helping hand to lend: UK aquaculture seeks to broaden its horizons

Aquaculture is an essential contributor to the world food security challenge, and every stakeholder has a role to play in the sector’s evolution, delegates were told at the recent Aquaculture’s Global Outlook: Embracing Internationality seminar in Edinburgh, Scotland.

Responsibility

Stocking rate effects on growing juvenile sunshine bass

A dose-response study was conducted in an outdoor biofloc system to begin quantifying the stocking rate production function for sunshine bass advanced fingerlings.

Aquafeeds

Reducing digestible protein in pond production of hybrid striped bass

A significant reduction is possible in the digestible protein level in commercial diets for hybrid striped bass using ideal protein diet formulation, a robust set of ingredient nutrient availabilities, and a higher level (45 percent) of muscle profile as the formulation target.