Automated monitoring systems offer better control of the culture environment

Life on the farm has gotten a little easier lately, thanks to monitoring systems built specifically for ponds. Systems equipped with dissolved oxygen (DO), temperature, and aerator amp-draw sensors now provide reliable pondside automation to fish and shrimp growers. Readings can be observed at the pondside, at a remote computer screen, or even on a handheld device carried in a vehicle. Aerators are automatically turned on/off and alarms or pagers signal problems to personnel.

“It’s allowed me to sleep with a lot more confidence,” says Mississippi catfish grower Chip Otts.

Double duty

In fact, Mr. Otts has plenty to occupy his full-time attention. As the sales manager of the local tractor dealership, his time is valuable. Splitting duties between tractor sales and his catfish production ponds, Mr. Otts must have assistance that is reliable. With a pond monitoring system at each of his five ponds, he is able to program the DO at which aerators are turned on, and can review the readings on his rounds, in the truck, or in the comfort of his home. With a computer stationed in his bedroom, he is able to review the present status, as well as the past trends of dissolved oxygen and temperature.

And by turning the aerator control over to his system, electricity use and diesel tractor run time have dropped significantly. Before the automated system, his aerators were controlled by timers, which turned them on/off regardless of the need. After switching to automation, the electrical aerators have run at least three hours less each night, while tractor- driven aeration has been nearly eliminated. “And it has allowed me to manage my ponds more aggressively, in terms of stocking and feeding,” says Mr. Otts.

Running lean

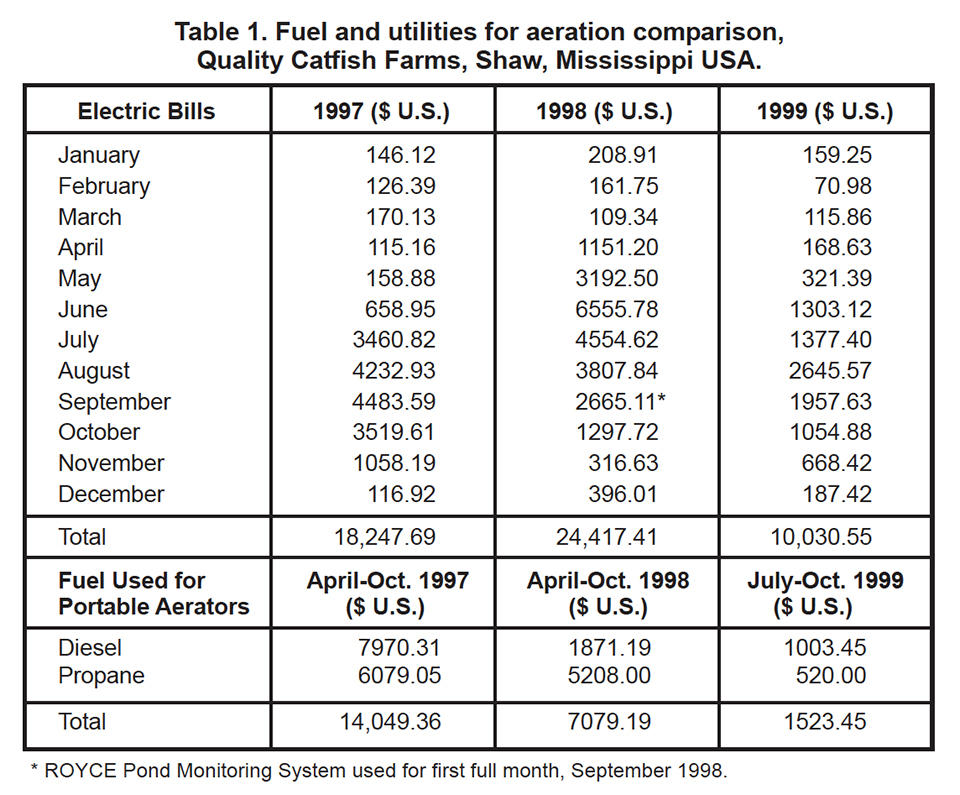

In the hands of Charlie Ellis, a catfish fingerling producer, the pond monitoring system has greatly reduced his need for extra labor. In fact, with fourteen ponds and only one assistant, Mr. Ellis is able to keep his team lean and his costs down. By turning on aeration at precise DO setpoints, water quality is more predictable and emergencies are limited. The only surprise came when Ellis reviewed the change in his aeration costs over a three-year period. The dramatic story is shown in Table 1, reflecting the combined benefit of automating the aerators, and the subsequent reduction in emergencies that called for tractor-based aeration. It shows monthly expenditures for electricity and fuel for the last four years, with the adoption of the automated system midway through the timeline.

Mr. Ellis points out that, like many farms, nightshift personnel will often run aerators regardless of the immediate need, just to avoid potential problems. This “play it safe” approach is admirable when considering the value of inventory in a pond, but it can lead to overly expensive utility bills. After seeing how reliable his automated system turned out to be, Ellis was able to eliminate the extra summer/night labor that would normally monitor DO manually with a portable meter. The cost savings are paying for the system and then some.

Bloom management and aerator maintenance

In addition to the immediate cost savings, continuous pond monitoring allows growers to control other variables with more precision. For a fingerling or shrimp operation, the status of the bloom is very important. Armed with continuous data for oxygen and temperatures, pond managers can better control the timing of fertilization and zooplankton cycles with stocking and feeding practices.

Algal blooms are often observed for color and turbidity. While this is valuable information to the experienced grower, it can now be supplemented with DO and temperature trends over the past few hours, days, or weeks. Growers find they are able to anticipate impending blooms that might otherwise crash or turnover, by watching the daily peaks in DO levels.

Measures like aggressive aeration, water exchange, or chemical control can be used in a proactive mode, rather than in response to a crisis. In situ turbidity and pH/CO2 sensors with self-cleaning capability are also available, providing the grower with a more complete picture of pond water quality. And with amp-draw sensors installed on the aerators, growers are able to anticipate maintenance required on floats, motors, gearboxes, or bearings, further eliminating surprises.

Pushing production limits

In concert with pondside observations, growers using automated pond monitoring systems have better control of the pond culture environment. And with that control comes the confidence to push production to new limits. Precise control of aeration and oxygen levels allow the aggressive manager to provide the right degree of push to his production while controlling risk and costs.

“We believe that the time is very close when growers will not be able to remain competitive without one of these systems,” says Chip Otts, referring to the southeastern U.S. catfish industry. With well over 700 ponds in the U.S. being monitored this way, the systems have proven themselves worthy.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Randy Lovell

President

Balanced AquaSystems

1051 Swanston Drive

Sacramento, California 95818 USA[109,111,99,46,115,121,115,97,117,113,97,100,101,99,110,97,108,97,98,64,111,102,110,105]

Tagged With

Related Posts

Intelligence

10 takeaways from GOAL 2019 in Chennai, India

The Global Aquaculture Alliance held its GOAL conference in Chennai, India, and recruited a host of experts in various fields to share their expertise.

Intelligence

A model for estimating pathogen variability in shellfish

This study reports on the development of a mathematical model for the shellfish depuration process and its impact on norovirus levels found in shellfish.

Health & Welfare

Acclimating shrimp postlarvae before pond stocking

Shrimp postlarvae acclimation before stocking into the various growout systems (ponds, raceways, tanks) is a critical – and often overlooked, sometimes taken for granted – step in the shrimp culture process. Various water quality parameters should be changed slowly so that the young shrimp have the time to gradually adapt to the new conditions.

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.