Assessing the characteristics of a major aquatic feed ingredient

Worldwide, soybean meal has the largest market share of all protein meals used in the production of single-stomach animals, and is becoming a major component of modern aquaculture feeds. Interest in vegetable-protein-only feeds for aquaculture is increasing with recent concerns over the potential for disease transmission from animal protein meals reflected in Bovine Spongiform Encephalopathy and Salmonella.

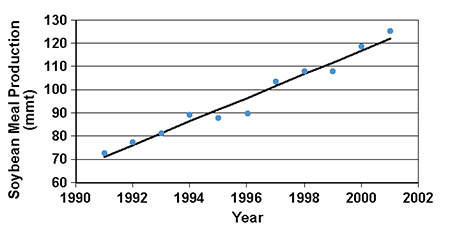

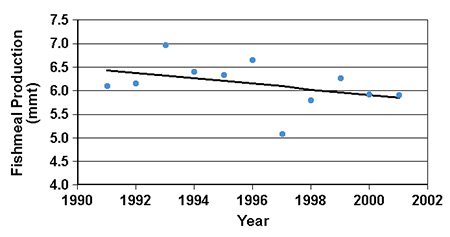

Furthermore, fishmeal is becoming increasingly expensive, with variable supply and long-term declining fishery resources. Figs. 1 and 2 compare the global supply of soybean meal to fishmeal over the past 10 years.

Production

The cultivation of soybeans (Glycine max) originated in China and has been used for centuries in food production. For animals, the plants were mostly used as a hay crop until around 1917, when Osborne and Mendel found that good growth could be obtained if soybeans were heated prior to incorporation into animal diets. It was later found that heating caused a denaturation of the protease inhibitors that interfere with digestion.

USDA 2001.

In 2001, over 125 million metric tons of soybean meal were produced from a soybean production of 183 million MT. The major global soybean producers and their approximate portions of total 2001 production were: United States, 41 percent; Brazil, 20 percent; Argentina, 14 percent; China, 8 percent; and India, 3 percent.

Proximate composition

Table 1 shows the U.S. National Oil Processors Association specifications for soybean meal. In the U.S., both 44 percent-protein and 48 percent-protein soybean meal are available. The nutrient levels of soybean meal samples from various international locations are given in Table 2.

The soybean meal from the U.S. was dehulled, as noted by the high protein level and low level of crude fiber. The other meals were mostly represented by nondehulled samples. Meals from Brazil and India were higher in protein than meals from Argentina and China, with comparable average fiber levels.

Swick, U.S. National Oil Processors Association, Table 1

| Nondehulled | Dehulled | |

|---|---|---|

| Protein, minimum | 44 | 47.5-49 |

| Fat, minimum | 0.5 | 0.5 |

| Fiber, maximum | 7.0 | 3.3-3.5 |

| Moisture, maximum | 12.0 | 12.0 |

| Anticaking agent, maximum | 0.5 | 0.5 |

Swick, Nutrient analysis of soybean meal, Table 2

| United States | Brazil | Argentina | India | China | |

|---|---|---|---|---|---|

| No. samples tested | 937 | 120 | 78 | 69 | 46 |

| Crude protein (%) | 48.1 | 46.1 | 43.5 | 46.8 | 45.0 |

| Crude fiber (%) | 2.88 | 5.21 | 5.54 | 5.89 | 5.20 |

| Ash (%) | 6.21 | 5.73 | 5.89 | 7.11 | 4.16 |

| Fat (%) | 1.43 | 1.54 | 1.70 | 1.24 | 1.45 |

| Urease, D pH | .05 | .04 | .04 | .06 | .04 |

| Protein sol. in .2% KOH | 85.6 | 83.6 | 79.9 | 76.3 | 83.4 |

| Lysine (%) | 3.04 | 2.84 | 2.70 | 2.86 | 2.74 |

| Lysine: Protein | 6.32 | 6.18 | 6.21 | 6.09 | 6.09 |

| Methionine (%) | .68 | .63 | .63 | .65 | .64 |

| Met + Cys (%) | 1.36 | 1.30 | 1.27 | 1.31 | 1.30 |

| Threonine (%) | 1.87 | 1.78 | 1.72 | 1.79 | 1.76 |

| Tryptophan (%) | .68 | .61 | .58 | .62 | .60 |

Table 2. Nutrient analysis of soybean meal from different countries.

Fiber

Virtually all the meal produced in the U.S. is dehulled before oil extraction, which brings the crude fiber content down from around 7 percent to about 3 percent. Fiber is then added back to the meal when a customer specifies 44 percent meal. Meal with the lowest possible fiber content and highest protein content should be specified for aquaculture. The cellulose in soybean hulls is not digestible to fish and will degrade the pellet quality and water stability of finished feed.

Digestible energy

A point often overlooked by nutritionists is that dehulled soybean meal has not only a higher protein and amino acid content than nondehulled meal, but also a higher digestible energy content. A simple calculation shows that removal of 5 percent indigestible fiber and ash from nondehulled soybean meal increases digestible energy by more than 150 kilocalorie per kilogram.

Protein and amino acids

“Crude protein” content – as the name implies – gives only a rough estimate of the level of digestible amino acid content in soybean meal. Soybeans grown from seeds with unimproved genetics under harsh, arid, unfertilized conditions often have higher crude protein content, when compared to those grown from improved seed under ideal conditions.

Lysine content

Lysine content, however, is lower in the unimproved varieties. This is due to differences in the relative abundance of the various storage proteins contained in beans (such as glycinin and conglycinin) and the Kunitz and Bowman Burk trypsin inhibitors. Production of trypsin inhibitors, which have a protective function in the plants, is induced during stress.

Quality assessment

Soybeans are processed by heat tempering, cracking, flaking, expansion, oil extraction with hexane, and final toasting using steam at a precise temperature for a specific time.

Toasting

The toasting process is critical to denature and destroy antinutritional factors but not damage nutrient protein fractions. The antinutritional trypsin inhibitor is a major concern, as it binds to and inactivates digestive enzymes. Digestion is reduced and the animal that eats the meal attempts to produce more enzyme to make up for the excreted loss. As these digestive enzymes are rich in sulfur amino acids, a methionine deficiency occurs and growth is affected.

On the other hand, slight to moderate overtoasting results in poor bioavailability of lysine due to formation of Amadori and/or Maillard reaction products. Free amino groups in the lysine react with sugars during heating to produce these indigestible polymers. The degree of degradation is undetected in the routine amino acid assay, as the sugars that bind to lysine during overtoasting are released during the acid hydrolysis step in the assay.

Urease test

Several tests are routinely done to assess the adequacy of heat treatment during soybean processing. A simple one that is widely used in crushing plants and feed mills is the urease test.

The presence of active trypsin inhibitor is often indirectly determined by measuring the activity of urease enzyme present in soy. Soybean contains urease, an enzyme that converts urea to ammonia. Although urease in soybeans is not nutritionally significant to fish species, it is inactivated at a temperature similar to that required for destruction of trypsin inhibitors.

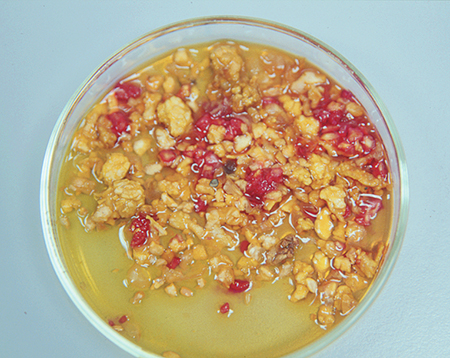

The urease test is much cheaper and easier than the trypsin inhibitor assay. In the urease test, a sample of soybean meal is mixed with a small amount of urea. The resulting ammonia increases pH, which can be measured with a pH meter or an indicator dye such as phenol red. The official method has been published by the American Oil Chemists Society.

Soybean meals with a urease value above 0.3 units of pH rise are considered undertoasted. Meals below 0.02 units of pH rise may be overprocessed or still of good quality.

KOH protein solubility

Overtoasting of soybean meal can be estimated by measuring protein solubility in a solution of 0.2 percent potassium hydroxide (KOH-PS). There has been great interest in this procedure, as its results are correlated to growth rates in poultry and swine.

Results suggest a decline in performance at less than 72 percent KOH-PS. Scientific investigations in a commercial crushing plant have shown high animal performance and lysine digestibility obtained in meals with high KOH-PS, and high urease activity when compared to meals with low KOH-PS and zero urease activity.

Protein dispersibility

The protein dispersibility index has been used in the food industry for over 25 years. Recently, this test gained attention as a method for distinguishing the quality of soybean meal for feed use.

The protein dispersibility index measures the amount of soybean meal protein dispersed in water after blending a sample with water in a high-speed blender. Results of experiments suggest this test may be useful to further distinguish the quality of soybean meal samples that are considered of high quality based on urease and KOH measurements.

High-performance meals

Typical commercial soybean meals have protein dispersibility index values around 15 percent. Several soybean-crushing plants around the world are marketing “high-performance” dehulled soybean meal with high PDI values of 30 to 50 percent, low urease values (below pH 0.05) and high KOH-PS above 90 percent. These meals have significantly higher amino acid and energy digestibility, and would be expected to give better performance than typical commercial soybean meals in fish feed.

Conclusion

Soybean meal has one of the best amino acid profiles relative to other vegetable-protein meals. Relative to fishmeal, soybean meal is rich in lysine, but deficient in methionine and cystine. Utilization of soybean meal by fish is variable, but with adequate oil, mineral, and possible amino acid supplementation, properly toasted soybean meal is capable of replacing much of if not all the fishmeal in diets for many aquaculture species.

Soybean meal is readily available in most world markets at a lower cost than fishmeal. Soybean meal is traded on the basis of weight, moisture, protein, fat, and urease level. Growth, however, is more directly related to the available energy and amino acid content of soybean meal. Feed mill purchasers often simply calculate the price per percent protein to determine the value of soybean meal. Although this may be somewhat useful, it is not completely valid when comparing meals of different fiber and ash content or meals from different origins.

(Editor’s Note: This article was originally published in the April 2002 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Robert A. Swick, Ph.D.

American Soybean Association

541 Orchard Road

#11-03 Liat Tower

Singapore 238881[103,115,46,116,101,110,46,99,105,102,105,99,97,112,64,115,97,114,97,115,97]

Tagged With

Related Posts

Aquafeeds

A look at India’s fish feed industry

India's fish-farming industry makes limited use of modern feeds, providing potential for the feed sector to grow. Commercial feeds are predominantly used for pangasius farming, followed by a rising popularity in carp culture.

Aquafeeds

A look at corn distillers dried grains with solubles

Corn distillers dried grains with solubles are an economical source of energy, protein and digestible phosphorus to reduce feed costs and fishmeal usage.

Aquafeeds

A push for rapeseed as a viable aquafeed ingredient

One Germany-based company says rapeseed protein concentrate, or RPC, can help aquafeed manufacturers meet growing demand.

Aquafeeds

ASAIM addresses challenges to growth of marine fish farming in Southeast Asia

In its efforts to advance sustainable aquaculture practices and the use of soy-based feeds in Southeast Asia, the American Soybean Association International Marketing Program (USAIM) has identified several challenges.