Inclusion of protein hydrolysates and spray dry plasmas has resulted in performance gains

Changes in production technology, marketing and feed ingredients are key areas for the structural transformations necessary for the aquaculture sector to grow. Today, with improved genetic techniques, novel genetic lines are being bred for maximum efficiency over a shorter production period with lower feed conversions. Thus, having the correct amount of micronutrients present in diets is crucial.

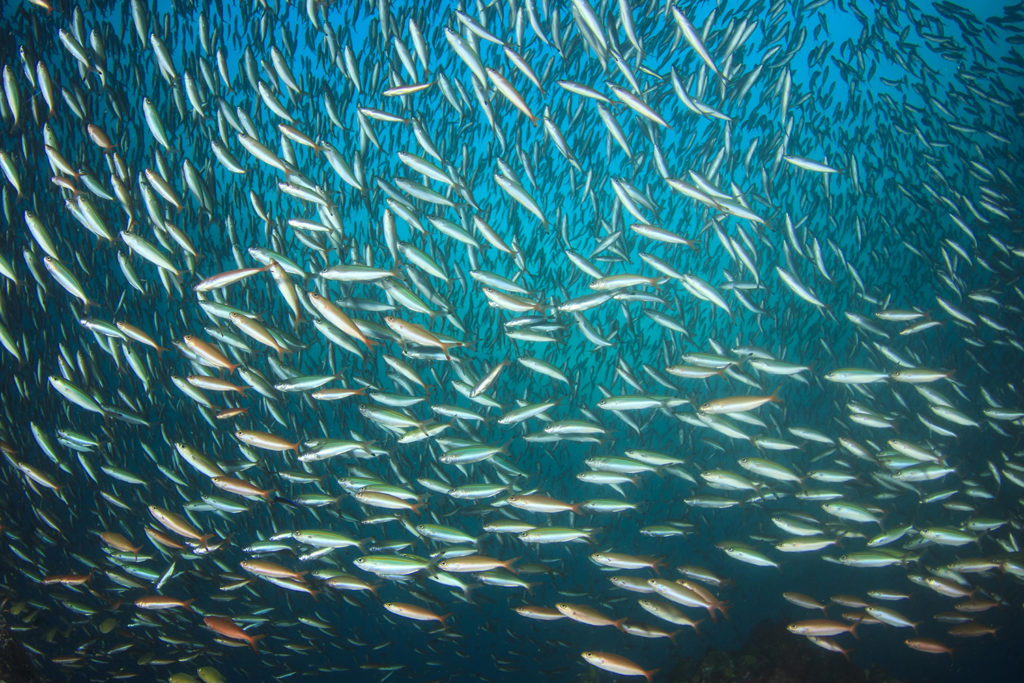

The rapid growth of aquaculture worldwide has made the industry increasingly dependent upon the use of external feed inputs, and in particular the use of compound aquafeeds. Fishmeal has always been the main source for quality protein and the preferred choice of nutritionists, especially in feeds for the youngest ages. But with the market volatility of fishmeal, as well as rising sustainability concerns, the aquaculture feed industry is looking for cheaper sources of protein to substitute for fishmeal.

In practice, formulating low-fishmeal aquaculture feeds requires the use of combinations of several ingredients, since most feedstuffs have significant nutrient and functional limitations, and cannot be used individually at high levels in the diets of most aquaculture species.

Animal byproducts

Animal byproducts are well accepted as aquafeed ingredients these days due to the short supplies and escalating cost of fishmeal. Protein content in animal byproducts is higher, and their complement of indispensable amino acids is superior to those of plant origin. They are also less expensive than fishmeal.

However, most single animal byproducts are unable to completely replace fishmeal. Combinations of different animal byproducts are more effective in achieving complete and balanced nutritional profiles than any single by-product.

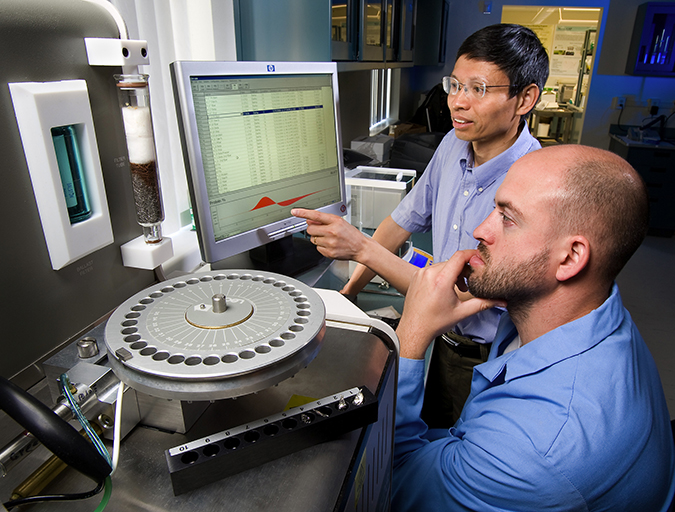

While feed manufacturers can source different byproducts and use them directly in their diets, an alternative is to prepare a protein concentrate by pre-blending the ingredients. Table 1 shows the nutritional composition of a few animal protein concentrates in relation to fishmeal. These products are of high protein content and less expensive when calculated as a digestible unit of protein per cost-unit.

Nates, Comparison of several animal by-product, Table 1

| Ingredient Content (%) | Ingredient Content (%) | Ingredient Content (%) | Ingredient Content (%) | Ingredient Content (%) |

|---|---|---|---|---|

| Fishmeal | 100.0 | 0 | 0 | 0 |

| Feather meal | 0 | 30.0 | 45.0 | 45.0 |

| Poultry meal, feed grade | 0 | 60.0 | 45.0 | 10.0 |

| Blood meal | 0 | 10.0 | 10.0 | 0 |

| Meat and bone meal | 0 | 0 | 0 | 45.0 |

| Nutrient Content (%) | Nutrient Content (%) | Nutrient Content (%) | Nutrient Content (%) | Nutrient Content (%) |

| Protein | 65.2 | 68.6 | 71.1 | 61.5 |

| Fat | 8.9 | 10.3 | 9.3 | 9.5 |

| Ash | 18.6 | 14.4 | 11.7 | 15.5 |

| Lysine | 4.9 | 3.4 | 3.2 | 2.3 |

| Arginine | 3.7 | 4.3 | 4.4 | 4.0 |

Using a protein concentrate offers several advantages over fishmeal use. The concentrates simplify traceability, as manufacturing facilities are typically certified. They also reduce the need for feed manufacturers to manage logistics and inventories for multiple separate animal byproducts.

Each concentrate is tailored to a specific nutritional composition, and quality assurance in the blending process manages natural variations in the nutritional quality of the product ahead of the feed-manufacturing process. In addition, concentrates can be supplemented with crystalline amino acids, attractants and sources of other vital nutrients to closely match the profile of fishmeal.

Fishmeal analogs

These supplemented concentrates are referred to as “fishmeal analogs” (FMAs). A fishmeal analog may contain ingredients like blood meal, squid meal or squid liver powder, meat and bone meal, feather meal, poultry byproduct meal, soy protein concentrates and crystalline amino acids, especially lysine and methionine.

In addition, to ensure that an FMA and the artificial feed in which it is used will be perceived as suitable food, it should leach a continual plume of attractants rich in free amino acids, especially taurine, glycine and other low-molecular-weight organic compounds such as nucleotides and nucleosides. Key immunoregulatory compounds and low-molecular nitrogen compounds can also be added to the mix. These include lectins, biogenic amines, antioxidants, phenolic compounds, sterols and long-chain fatty acids.

Feeding trials have been conducted to determine the proper amounts of concentrates or FMAs that can replace fishmeal protein in feed for several species including trout, catfish, grouper, cobia, tiger shrimp and white shrimp. Results showed that weight gain and feed efficiency were slightly lower in animals fed 100 percent FMA-based diets when compared to fishmeal-based diets.

Most results indicated that FMAs can substitute for up to 80 percent of the fishmeal protein in feeds. For example, poultry by-product meal mixed with hydrolyzed feather meal can replace 80 percent of the total protein in shrimp diets without growth retardation. Up to 80 percent of the fishmeal protein in diets for several marine fish species has been replaced by a combination of meat and bone meal, and blood meal with no adverse effect on growth, survival or feed efficiency.

Less pollution, better performance

For carnivorous fish species, aquaculture feeds usually contain a high level of fishmeal, as well as large amounts of phosphorus, which is discharged into the environment as feces and urinary excretion. The use of FMAs can considerably improve the status of phosphorus in aquaculture feeds, and low-cost diets can be less “polluting.” Furthermore, the addition of specialty animal byproducts, including protein hydrolysates and spray dry plasmas, to fishmeal analogs has resulted in performance gains in several aquaculture species.

Products derived from pig intestines have been developed with more than adequate production and sanitary results, in most cases improving the palatability of feed. A high percentage of this protein source is in the form of peptides, which increase the digestibility of the FMA products. The pig intestine peptides are a byproduct of heparin production, and therefore have high levels of quality and production control.

These products are beneficial in diets for early rearing of aquatic species for which fishmeal is presently considered indispensable. It is also important to keep in mind that the most rigid test for an FMA-based aquaculture feed is its use in a complete production cycle that includes broodstock gamete quality evaluation.

Perspectives

High-quality protein concentrates can be manufactured according to the specific requirements of feed mill operations with inclusion rates that vary from 5 to 50 percent in the final feed formulations. Different concentrates contain different levels of major nutrients such as protein, energy and minerals, so the selection of an appropriate concentrate should consider the availability of ingredients at the location. The feed can then be formulated to balance the nutrients as part of the culture animals’ total diet and tailored to suit any particular requirements relative to the culture system.

(Editor’s Note: This article was originally published in the September/October 2013 print edition of the Global Aquaculture Advocate.)

Authors

-

Sergio Nates, Ph.D.

Latin American Rendering Association

Edf. Arinsa, Planta Baja

Sabana Oeste, San José, Costa Rica[103,114,111,46,101,114,112,97,108,97,64,115,101,116,97,110,111,105,103,114,101,115]

-

Kent Swisher

Vice President, International Programs

National Renderers Association, Inc.

Alexandria, Virginia, USA

Tagged With

Related Posts

Aquafeeds

Aquaculture feed composition helps define potential for water pollution

A study found that feed for salmon and trout had higher organic carbon concentrations than did catfish, shrimp and tilapia feeds. Nitrogen and phosphorus concentrations were similar among salmon, trout and shrimp feeds, and higher than those in catfish and tilapia feeds.

Aquafeeds

IFFO: Future contributions of marine ingredients in aquafeeds

Fishmeal is still the most nutritious source of protein for aquaculture diets, having a wide range of essential amino acids and a high digestibility, while fish oil is still the only commercially available source of long chain omega-3 for aquaculture diets – both are the foundation of aquafeeds.

Aquafeeds

Alternative feed ingredient universe to convene at F3 meeting

What started out as a simple yet ambitious contest to drive innovation in the aquafeed sector has evolved into a fully global competition – and collaboration – amongst ingredient suppliers and feed manufacturers.

Aquafeeds

Aquaculture’s input efficiency shines as FIFO ratios improve

The latest Fish In:Fish Out (FIFO) ratios calculated by IFFO – The Marine Ingredients Organisation shows that every kilogram of wild fish utilized in aquafeeds results in a total of 4.55 kilos of farmed fish produced.