Products from marine invertebrates face long odds for approval

Perhaps the most difficult problem associated with the development of any drug candidate from marine sources is the collection of enough source material to enable scientists to evaluate the purified compound for its intrinsic chemical and biological properties. This hurdle is often thought to be the reason development of “drugs from the sea” has not yet realized its potential when compared to work with compounds from plants, terrestrial microbes and chemical laboratories.

Aquaculture potential

For marine invertebrates or algae, aquaculture techniques used for years in the production of food organisms and commodity chemicals such as agar and agarose are appealing for large-scale production – where it may be necessary to produce tons of the producing organism to isolate grams of a compound for preclinical and clinical testing.

However, significant problems that do not occur in the production of foodstuffs and chemical commodities must be considered in any system for pharmaceutical production, due to the requirements of government agencies that control the quality and efficacy of human drugs. The most demanding of these requirements is that the production of biomass and content of the compound or compounds within organisms must be reproducible.

Good manufacturing processes

For example, in the United States, any compound from nature, chemical synthesis, or any combination thereof must be produced in a reproducible fashion and processed under the “current good manufacturing processes” (cGMP) described in the U.S. Code under 21CFR11.

This does not stop production of the biomass under normal marine conditions, but places controls on the aquacultural process and subsequent processing, which can be very expensive and time-consuming. Even more importantly, before any “drug” can be used in a human clinical trial, three separate production runs of a material and its chemical specifications must fall within the same limits in each run.

Good laboratory practices

What this effectively means is that normal aquaculture systems may be used to produce biomass that is subsequently processed in a chemistry laboratory under a less-stringent set of rules known as “good laboratory practices,” which guide the basic chemical and biological studies. This is usually performed in small pilot plants with mid-sized processing capabilities up to 100 kg of biomass.

Suitable records are kept, and the final products are worked up from a series of batches. This permits the lab chemists to specify the “normal limits” of other, frequently similar compounds in the final preparation.

Extensive testing

The reason this type of analysis is so important is that the purified material will be tested in a variety of in vitro and in vivo model systems, where other biological activities might be associated with the chemical structure. It could be disastrous if the activity one wants is in fact associated with a very small contaminant. Or the compound could be “nonspecific” (active in a variety of biological systems as well as the targeted one). Perhaps the majority of observed animal toxicity is associated with a contaminant.

If a compound does pass all these tests, the challenge is then to produce enough of the drug candidate under cGMP requirements so the next series of hurdles can be overcome before it can be used in man. Perhaps the biggest hurdle is that a suitable formulation must be made that will allow a drug to be given to an animal (and ultimately man) without extensive development.

In the case of anticancer treatments, which usually require hospitalization for administering, formulations can only be delivered by injection or in-dwelling catheters. In contrast, treatment of chronic diseases such as high blood pressure or high cholesterol require an oral formulation that allows the use of a simple pill.

Once a suitable delivery method is established, developers must demonstrate they can get a high-enough level of the drug in an animal to show effect and, of critical importance, demonstrate the level remains high enough for long enough to work. Drug residues must be shown to be excreted and not cause liver or kidney problems, nor produce toxic compounds within the body.

Once these data are acquired (for compounds that are not potential drugs for cancer), two-year toxicity studies are required to demonstrate safety. With cancer treatments, the toxicity testing is much shorter. Assuming all results are reasonable, an “investigational new drug application” can be submitted for permission to use the drug candidate in human trials. It is of course wise to involve administering government agencies throughout the process.

Long road

As can be seen, initial aquaculture production is only the beginning of a very long road that leads through chemistry, biological testing, process refinement, stringent production and clinical trials following regulatory approval.

To put some perspective on the process, for every 10 “drug leads” that go into the preclinical testing process described above, only one will generally enter clinical trials in man. For every 10 that enter clinical trials, two will become drugs approved somewhere in the world for a particular disease. Therefore the overall odds of taking a potential compound from preclinical testing to drug approval are somewhere around 1:50.

However, and this is significant, the number of compounds that have to be found, isolated, purified, chemically identified and then subsequently obtained in 100-mg or greater quantities for initial evaluation in discovery to obtain just one bona fide preclinical lead can only be calculated once a drug is approved, but is measured in the tens of thousands.

Role of aquaculture

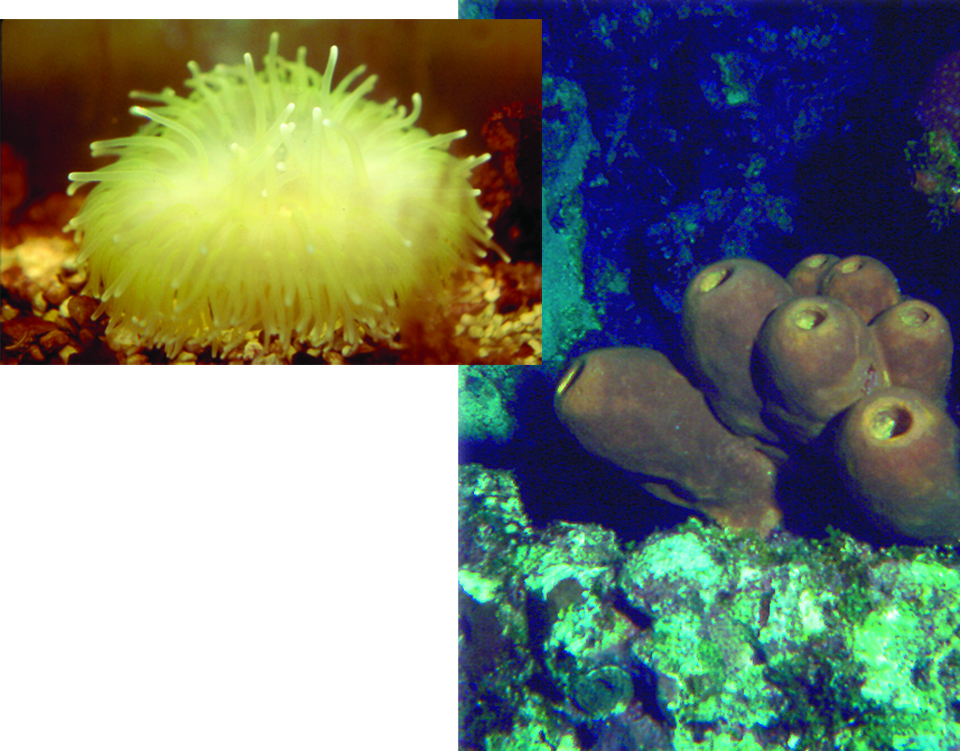

In spite of these odds, aquaculture production of the original material was an absolute necessity for the current clinical trials of several antitumor agents that use marine-derived compounds or a chemical made in a laboratory that required the structural information from a marine-derived compound.

These drug candidates demonstrate the interrelations between chemistry, marine biology and aquaculture. The materials that finally went into clinical trials were produced by wild collection (Bryostatin 1 from Bugula neritina), chemical synthesis of a derivative following wild collection of a deep-water sponge (E7379 derived from halichondrin B isolated from a Lissodendoryx sp.), and semisynthesis of a natural product following fermentative production of a close relative (Et743 from Ecteinascidia turbinata).

What should be taken into account for the future is the discovery that in at least two of the cases above (Bryostatin and Et743), it is highly probable the actual producing organisms are not the marine macroorganism from which the drugs were originally isolated, but commensal microbes that live in or on the macroorganisms.

(Editor’s Note: This article was originally published in the December 2004 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

David J. Newman

Natural Products Branch

Developmental Therapeutics Program

NCI-Frederick, P. O. Box B

Frederick, Maryland 21702 USA[118,111,103,46,104,105,110,64,97,50,50,110,100]

-

Gordon M. Cragg

Natural Products Branch

Developmental Therapeutics Program

NCI-Frederick, P. O. Box B

Frederick, Maryland 21702 USA

Related Posts

Responsibility

The blue dimensions of aquaculture

Authors review global aquaculture production, including development, farming systems, environmental concerns and further growth potential.

Intelligence

A brief look at genetically modified salmon

If approved by FDA, fast-growing genetically modified salmon will provide a safe and nutritious product similar to other farmed Atlantic salmon.

Health & Welfare

Advances in tilapia nutrition, part 2

Nutrition has an important role on growth, performance and flesh quality of tilapia. Part two of this two-part series looks into mineral supplementation and feeding strategy.

Health & Welfare

American fisheries society calls for immediate-release fish sedatives

The absence of practical immediate-release sedatives for fish jeopardizes fish, fisheries, fish culture and research, posing risks to aquatic resources as well as those handling fish.