A review of ingredients, formulas, operating costs

Ingredients are the major cost in the operation of a feed mill, so it is very important that feasibility analyses include real ingredient costs as well as manufacturing costs. The sum of the ingredient, fixed, and variable costs provides the total operating cost for the mill.

Ingredient selection requires knowledge of formulation formulas. Therefore, from the planning stages, the owner of the project should engage the services of a qualified nutritionist or consultant who is very knowledgeable about shrimp nutrition.

https://www.aquaculturealliance.org/advocate/are-on-site-feed-mills-right-for-shrimp-farmers-part-1/

Nutritionist and ingredients

The nutritionist is responsible for providing a list of all ingredients and their total average annual usage. The nutritionist also identifies ingredient sources – imported as well as local – in order to have a better estimate of their costs when delivered to the proposed site of the new feed mill.

It is important to determine for each ingredient the required volume, delivery frequency and method of delivery (barge, train, truck, ship, others), import duties or restrictions, transit time, quality, supplier reliability and future volume requirements for growth over a period of five, 10 and 15 years. This information will be used later in the design phase to determine storage capacity and type.

For imported ingredients, it is common to have up to 90 days of storage capacity for ingredients such as soybean meal, 45 days for wheat, and 60 to 90 days for fishmeal. For feed mills located close to all sources of ingredients, storage capacity will be minimal – perhaps two to five days – in order to reduce storage and handling costs, but this certainly depends on the reliability of the suppliers.

Formula costs impact total investment

Once the ingredient usage and costs have been determined, the average formulation cost can be estimated. Table 1 presents the ingredient usage and total costs for the feed mill of an integrated shrimp farm that consumes 10,000 metric tons (MT) per year. The total estimated ingredient cost has been assessed for this case at U.S. $3.4 million.

Bortone, Estimated annual ingredient usage and formula costs, Table 1

| Ingredient | Origin/Country | C & F Port (U.S. $/mt) | C & F Port Feed Mill (U.S. $/mt) | Formula Mix, Average Consumption | Projected Annual Ingredients Consumption (mt) | Annual Cost (U.S. $) |

|---|---|---|---|---|---|---|

| Fishmeal | Chile | 675 | 700 | 8.00% | 800 | 560,000 |

| Fish oil | Local | 480 | 3.00% | 300 | 144,000 | |

| Ground kelp | Chile | 500 | 520 | 3.00% | 300 | 156,000 |

| Krill meal | Chile | 1,510 | 1,530 | 0.00% | 0 | 0 |

| Biokrill | Chile | 1,280 | 1,300 | 0.00% | 0 | 0 |

| Fish solubles | USA | 525 | 2.32% | 232 | 121,800 | |

| Menhaden fishmeal | USA | 630 | 21.13% | 2,112.5 | 1,330,875 | |

| Wheat | USA | 140 | 42.83% | 4,283 | 599,620 | |

| Soybean meal | USA | 235 | 18.19% | 1,819 | 427,465 | |

| Rice flour | Local | 230 | 0.00% | 0 | 0 | |

| Molasses | Local | 100 | 0.00% | 0 | 0 | |

| CaCO3 | Local | 30 | 0.00% | 0 | 0 | |

| Vitamin premix | Local | 6.8 | 0.20% | 20 | 136 | |

| Mineral premix | Local | 1,200 | 0.15% | 15 | 18,000 | |

| Liquid A | Local | 780 | 1.00% | 100 | 78,000 | |

| Cholesterol | Norway | 2,500 | 0.00% | 0 | 0 | |

| Salt | Local | 50 | 0.05% | 5 | 250 | |

| Antimycotic | Local | 2,000 | 0.13% | 13 | 26,000 | |

| Total | 100.00% | 9,999.5 | 3,462,146 |

Ingredient cost represents the largest portion of the operating capital the project needs to keep the mill in operation. This sum is in addition to the money needed to build the feed mill, which in this case was estimated at U.S. $7.5 million. Therefore, if the company does not have the option to finance the project, it will need U.S. $10.9 million available to invest in the operation.

Manufacturing costs

Feasibility studies also take a close look at variable and fixed costs. Costs that fluctuate with volume changes are variable costs. Fixed costs, on the other hand, are those that do not change with volume. However, they drop considerably with production increases.

Examples of fixed costs are salaries and wages, pensions, medical insurance, compensation insurance, depreciation of buildings and equipment, interest on invested capital, rent, taxes, licenses fees and office supplies. Examples of variable costs are maintenance costs, utilities (water, fuel, and electricity), pellet dies, rolls, telephone, postage, uniforms, safety, pest control, medical supplies and others.

The total fixed and variable operating costs can be used to determine the total cost required to manufacture feed. In some cases, increasing feed production can reduce or dilute fixed costs. The same may be true with labor costs, provided the number of man-hours does not increase to meet increased demand. In contrast, if production volume drops, labor costs per ton can increase dramatically.

Total costs, therefore, can be used to calculate the equilibrium point at which total volume sales is enough to meet all operating costs. An integrated feed mill that depends mostly on the demand of feed from its shrimp operation – and not on sales to third parties – will be less vulnerable to market fluctuations and have more predictable manufacturing costs.

Case analysis

Table 2 shows the total manufacturing costs estimated in the case analysis at around U.S. $135 per MT. The sum of the operating and formula costs (U.S. $346 per MT) gives a total cost of $481 per MT. The difference between the total cost of the integrated feed versus the cost of the local feed shows a total savings of approximately U.S. $198 per MT, or almost $2 million per year.

Bortone, Estimated total operating costs, Table 2

| Item | Comment | Value |

|---|---|---|

| Total ingredient cost (U.S. $/mt) | 346.20 | |

| Total manufacturing costs (U.S. $/mt) | Includes all fixed and variable costs | 135.00 |

| Total cost (U.S. $/mt) | Estimated cost of feed for the integration | 481.20 |

| Market reference average feed prices | Feed purchased to local supplier | |

| Company A-Z (U.S. $/mt) | 680.00 | |

| Difference vs. manufactured feed | Savings per mt | 198.80 |

| Total annual savings, (U.S. $) | Based on 10,000 mt feed consumption | 1,987,581.50 |

| Estimated feed mill cost (U.S. $) | Budget estimate based on feasibility study | 7,500,000 |

| Return on investment (years) | 3.77 |

With these figures, it would be feasible for the owner to proceed to the conceptual and detail design phases of a mill project. The return on investment can be calculated by dividing the estimated feed mill cost by the total annual savings/profits. In this case, the return on investment will take only 3.7 years. This information can be used to support or justify a loan with a financial institution.

Conclusion

Feasibility analyses can show if projects have an acceptable chance to succeed under the conditions considered. One condition is the volume of feed the operation requires, and even more importantly, the ingredient costs and availability.

Ingredient costs can be affected by volume. In most cases, large-volume purchases reduce the cost of the ingredients. This is why most large commercial feed companies have advantages over small ones when buying ingredients. Also, overall costs can be adversely affected by storage costs, transportation costs, import restrictions, import duties and taxes that increase total formula costs.

(Editor’s Note: This article was originally published in the June 2003 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Eugenio J. Bortone, Ph.D., PAS

5416 Lafayette Lane

Frisco, Texas 75035 USA[109,111,99,46,108,111,97,64,101,110,111,116,114,111,98,114,100]

Tagged With

Related Posts

Responsibility

Feeding affects pond water quality

Feeding allows much greater production of fish and shrimp, but nutrients in feed are not converted completely to fish or shrimp flesh.

Aquafeeds

Proper grinding of aquaculture feed ingredients

In grinding aquaculture feed to proper particle sizes, parameters of consideration include particle size distribution and pellet density.

Aquafeeds

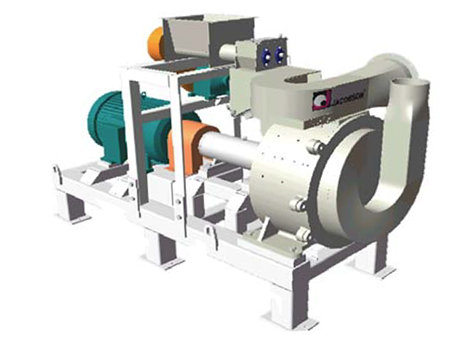

Twin screw technology for better extruded feeds

Extrusion processing can be a better alternative to produce high quality-low- polluting shrimp feeds. Extruded pellets with high water stability can be produced by controlling the Specific Mechanical Energy (SME) and without the inclusion of artificial binders. New extruders are equipped with state-of-the art SME controls that permit the adjustment of the SME to the desired range, to produce soft very hydrostable pellets.

Aquafeeds

Vacuum process supports high oil content in feed coatings

Evolving vacuum coaters can apply coatings to feed with up to 40 percent oil levels. It may soon be used to reduce inclusion levels of fat- and water-soluble vitamins in feeds.