Greater control is good business sense

The safety of the food we eat is an issue about which we all share concerns. The risks vary with the food type and origin, but regardless of the source, the challenges are to determine what the risks are, where they originate and what reasonable steps can be taken to lessen them. HACCP programs are developed with the goal of identifying and controlling food safety risks.

Aquaculture has been the focus of a great deal of publicity that purports significant risk, primarily from the use of certain types of chemicals to treat bacterial and fungal infections. While in many cases the real hazards are far from certain from a purely scientific standpoint, it is in the best interest of processors to ensure that any risk is minimized to the greatest extent possible.

Confidence through consolidation

Aquaculture is here to stay and will continue to supply an ever-increasing percentage of the seafood that humans consume. As with other agricultural sectors, the early commercial stages of aquaculture often included myriads of small businesses taking advantage of a relatively simple way to earn money.

As the sector matured, consolidation has occurred, with vertical integration an essential element of the process. Controlling the aquaculture supply chain from one end to the other, while not a guarantee, does, for example, allow greater levels of assurance that banned compounds are not used and that as new compounds are identified, they are specifically excluded.

Aquaculture product risks

Just what are the risks from aquaculture foods, and where do they enter the food chain?

- Risks that enter the cultured animal because of where it is produced. This is where the vertically integrated producer has an advantage over competitors. Controlling the source minimizes the risks. Examples of risks are antibiotic and chemical residues, certain pesticides and heavy metals, bacterial contaminants that indicate fecal contamination or could be problematic to consumers in certain food classes (i.e., raw versus cooked) and certain toxins.

- Risks that enter the animal during processing. Typically these are addressed by HACCP plans that analyze each step of the production process and address those risks that are potentially of serious physical harm to consumers. These can include gross metal contamination and some of the same risks above that enter the plant by inadequate control before raw material enters the product line.

- Risks when the consumer purchases and subsequently uses the product. These risks are completely beyond the control of the processor and can include things like improper storage by the vendor or consumer, and/or preparation that leads to spoilage with subsequent consumer health problems. Extreme examples might be deliberate adulteration with the intent to harm.

Integration limits risks

Vertical integration in which corporations control the product from the first stages of production (maturation and hatchery) through the packaging in the processing plant is an excellent option to minimize the preventable risks outside the processing plant. Typically, these risks range from the improper (inadequate withdrawal times after chemical use, for example,) to illegal (application of antimicrobials banned in the country that is purchasing the product).

These risks are regulatory, although not necessarily biological. There are concerns that some antimicrobials are toxic – nitrofurans and malachite green are often cited as presumptive carcinogens, for example. But they are not typically problematic at the action levels set forth by legislators.

An action level of 1 ppm is equivalent to 1 gram per metric ton (MT). At 1 ppb, this is 1 mg per MT. While some compounds are toxic at these levels, it is widely accepted that none of the current regulatory action levels for antimicrobials in aquaculture pose real health hazards to consumers.

A number of arguments are made to justify the banning of specific compounds as being not allowed at any level in aquaculture products. One is that if specific antibiotics routinely used in human medicine are used routinely by aquaculturists, this could lead to the occurrence of resistant strains of human pathogens.

From a practical standpoint, it is unrealistic to expect farms to sacrifice crops and risk possible bankruptcy simply because someone has decided it is in the best interests of the public to disallow the legal use of specific compounds. This is complicated further when these compounds are metabolized to extremely low levels that pose no threat to consumers, only the processors.

Perspectives

Control over all aspects of the production process can mitigate problems and ensure that poor and underinformed choices are not made. In fact, several integrated companies have already certifiably demonstrated that they exert this control and have thus been the subject of less regulatory oversight because they can prove they provide a level of assurance that others cannot. Given that this is a potentially large advantage when facing the economic realities of multiple potential profit centers, vertical integration makes great practical and business sense.

(Editor’s Note: This article was originally published in the September/October 2009 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Stephen G. Newman, Ph.D.

President and CEO

AquaInTech Inc.

6722 162nd Place Southwest

Lynnwood, Washington 98037 USA[109,111,99,46,104,99,101,116,45,110,105,45,97,117,113,97,64,109,119,101,110,103,115]

Tagged With

Related Posts

Intelligence

Aquaculture leads fish production, consumption to new highs

The most recent biennial report from the Food and Agriculture Organization of the United Nations stresses the growing importance that aquaculture has as new records for global seafood production and consumption were reached in 2016.

Health & Welfare

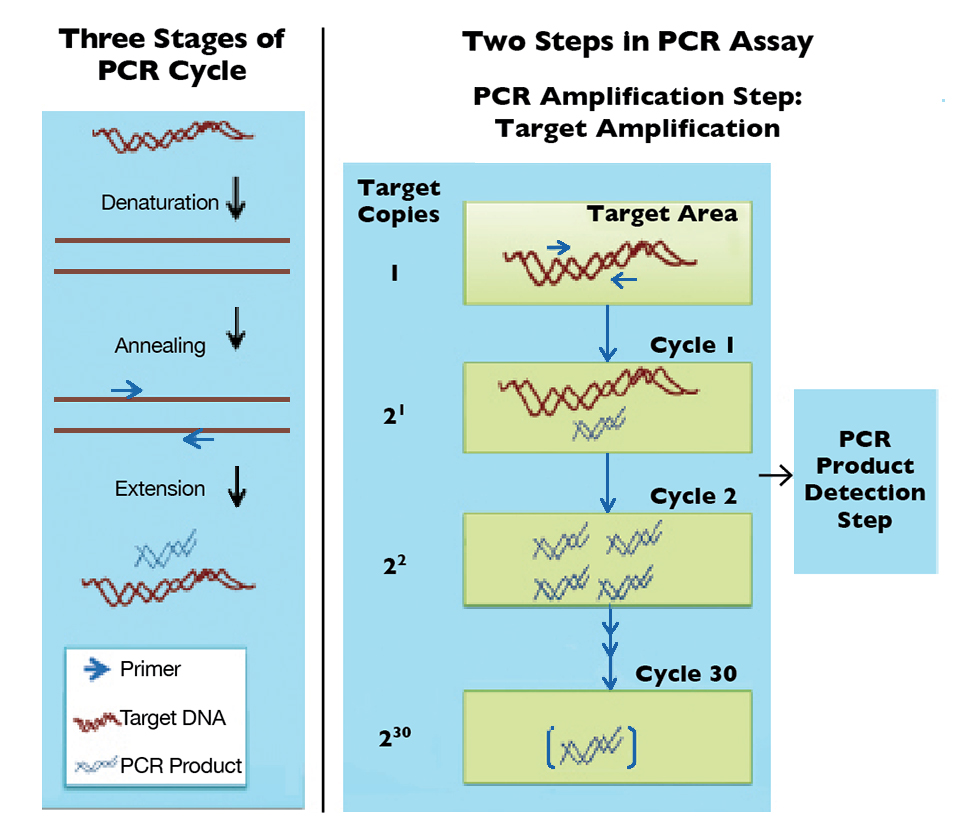

PCR-based tools aid biosecurity via detection of WSSV

Offering high sensitivity and specificity, polymerase chain reaction (PCR) assays are the most accepted molecular method for white spot syndrome virus (WSSV) detection.

Health & Welfare

Peru project studies blood cockles for stock enhancement, aquaculture

In Peru, some wild cockle communities have been so overfished that total fishing bans are being considered. A project was therefore established to develop sustainable spat production as a crucial step toward the implementation of a conservation strategy for blood cockles that fosters social aquaculture and stock enhancement. The project rested on the establishment of protocols for reproduction, larval culture and seeding; development of diagnostic tools for molluscan pathogens and the study of blood cockles’ genetic diversity.

Innovation & Investment

Pirarucu culture in the Brazilian Amazon

With their fast growth and ample light-flavored flesh, pirarucu present great potential. Industry growth is hampered by limited technology and management of domestication practices. Also, current commercial diets are typically not fully suited to the nutritional needs of pirarucu.