Study shows automation significantly more efficient than hand feeding

The continued success of shrimp aquaculture will rely on improvements in feed management and reductions in the labor requirements for production. This is particularly important for feeding of shrimp.

In general, shrimp farmers in the Americas feed twice daily as the labor and time required to feeding large ponds is considerable and viewed as too costly to support multiple feedings. In Asia, inexpensive labor and smaller production units allows for a higher frequency of feedings. In both cases, feed inputs are adjusted based on the use of historical data (e.g. feed tables) or through indirect measures of feed intake such as the evaluation of gut fill or the use of feed trays.

In all cases, there is no clear and direct measure of feed intake nor is there feedback from the shrimp in terms of the need for feed

Move to automated feeders

As the number of feedings is increased, shrimp performance is enhanced. This is presumably due to the eating habits of the shrimp as well as physical factors influencing the feed. Shrimp are benthic grazers that externally masticate their feed and have evolved to eat small quantities of food throughout the day. These qualities make managing feed inputs and delivering nutrients problematic as many of the essential nutrients are water-soluble.

Historically, shrimp farmers have relied on very stable feeds to allow shrimp to have access to the feed over an extended period of time; thus, minimizing the need for numerous feedings.

However, research has demonstrated that the longer a feed is exposed to leaching the poorer the nutritional value of the feed. For example, comparison of growth of shrimp fed feeds that have been leached for varying lengths of time (0, 0.5,1, 2, 4 hrs.) has demonstrated significant reductions in growth for shrimp offered feeds that were previously leached for more than one hour. These results clearly demonstrate an economic value for the feed to be in the water for as short a period as possible, meaning that numerous small feedings would be better than fewer large feedings.

Logically, the industry needs to move towards automated feeders that would allow small frequent feedings. Although, this minimizes the effect of leaching and addresses the need for shrimp to have access to feed over an extended period of time, it does not address intake issues.

In fish, adaptive technologies, also referred to as demand feeding, have been used for many years with good success. In its simplest form, this would be the observation of fish eating a floating feed for which the feeder offers feed based on the level of response as well as feed remaining on the surface. With automated systems this is often done using image recognition, which is restricted to clear water situation in which the feed and fish can be observed. These automated technologies rely on visual systems, which are not applicable to shrimp or their production systems.

Acoustic technologies

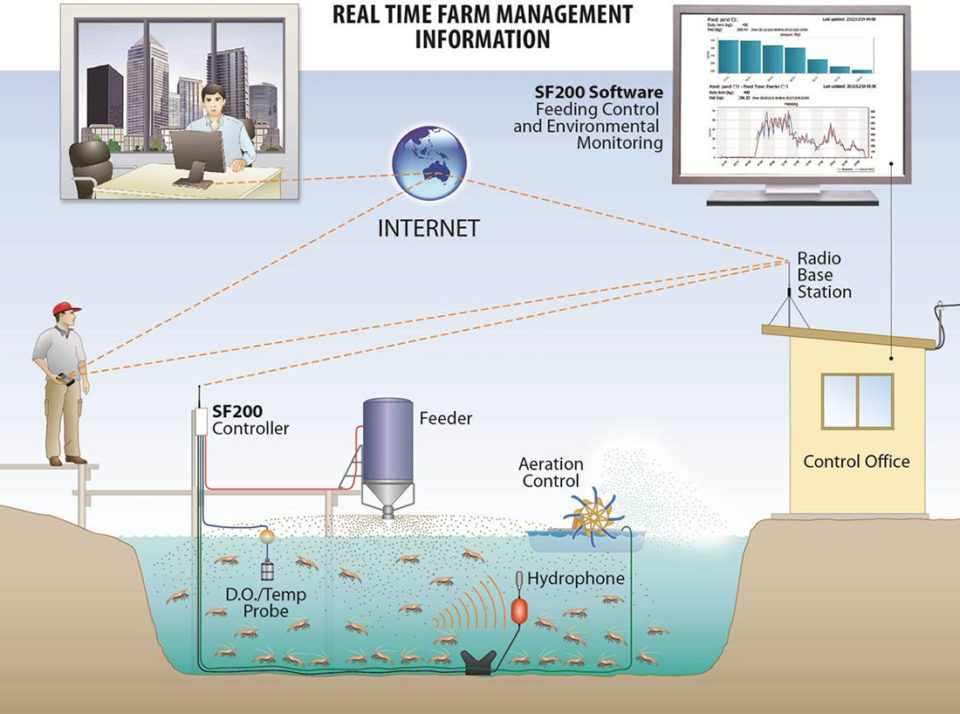

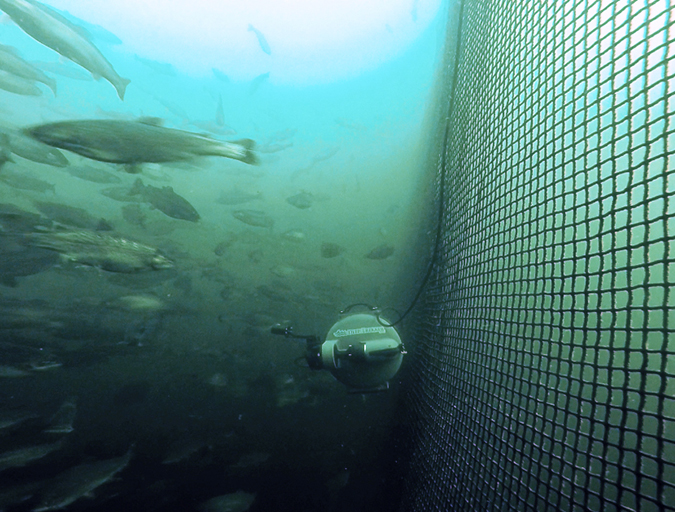

However, more recently acoustic technologies have been applied to shrimp. The AQ1 Systems (Tasmania, Australia) have recently developed the world’s first sensor-based feed control system that is applicable to shrimp (Fig. 1). This feedback-controlled feeding system uses sonic technology to measure feeding intensity.

The sound-feeding system has complex filtering algorithms to analyze shrimp feeding sounds and Adaptive Feeding Algorithms© to control feed outputs to match feeding intensity. The system can be equipped with sonic, temperature, and dissolved oxygen (DO) sensors that automatically log real-time information to a networked computer. This allows for real-time observations of feed demand as correlated to time of day and shifts in water quality parameters (temperature and dissolved oxygen).

This system has been installed in numerous commercial farms across a range of production technologies ranging from extensive to super intensive conditions. The acoustic monitors allow feeding activity to be monitored to provide real time adjustment of feed input based on demand. This means improved feed application during times of active feeding. As would be expected the improvement will vary but has improved feed utilization and growth rates across a range of technologies. The global improvements based on intensity are summarized in Table 1 and demonstrate the flexibility of these systems.

Davis, Auto feeding, Table 1

| SF200 System - Productivity Improvements | ||||

|---|---|---|---|---|

| GROWTH (%) | FCR (%) | SURVIVAL (%) | t/ha (%) | |

| Semi Extensive Ponds (8-15PL/m2) | 18.6 | 25.1 | 23.0 | 31.1 |

| Semi Intensive Ponds (15-40PLm2) | 34.9 | 18.3 | 14.5 | 36.0 |

| Intensive Ponds (40-120PL/m2) | 16.9 | 15.2 | 3.0 | 15.8 |

| Average Improvement | 23.5 | 19.5 | 13.5 | 27.6 |

As these technologies have a great deal of potential, we have initiated a series of studies to evaluate the use of automatic feeders to simply increase the number of feedings as well as the AQ1 systems to dynamically adjust feed inputs to shrimp demand. In our most recent research, we compared feed management strategies in pond culture of Pacific white shrimp (Litopenaeus vannamei) to evaluate the effects of feeding rates on the growth performance, production, water quality and economic returns.

Study setup

For this work a 13-week production trial was performed at the Claude Peteet Mariculture Center, Gulf Shores, Alabama with 16, 0.1 ha ponds stocked at 38 shrimp per square meter (initial weight 0.036 grams). Four treatments were used for this study; standard feeding protocol (SFP) which is based on an assumption of growth, FCR and an assumed mortality.

This translates to 1.56 grams of feed for each shrimp each week once the shrimp are larger than 2 grams. This is then used to calculate the quantity of feed which is fed twice daily by hand (8 a.m. and 4 p.m.), two solar timer feeder treatments programed to feed SFP increased by 15 or 30 percent, divided into 6 feedings per day, at 8 a.m., 10 a.m., 12 p.m., 2 p.m., 4 p.m. and 6 p.m. (Timer 15 and Timer 30), and on demand feeding using the AQ1 acoustic feeding system, fed between 7 a.m. and 7 p.m., limited to maximum of 15 kg/day or 150 kg/ha/day.

All ponds were fed using Zeigler Raceway 1.5 mm (40 percent P and 9 percent L) for first 15 days then Zeigler SI-35 2.4 mm (35 percent P and 7 percent L) shrimp grower diet for remaining weeks. All of the ponds were fed the same amount of feed the first four weeks, however the timer and AQ1 ponds were fed six times a day started at week three with the AQ1 acoustic controls self-managing feedings starting at week five.

Results

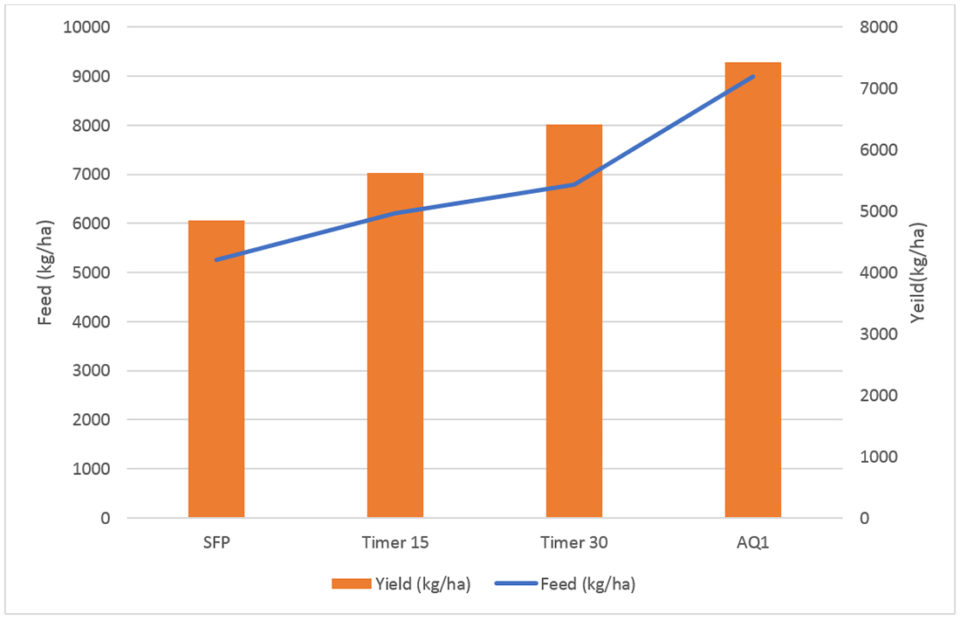

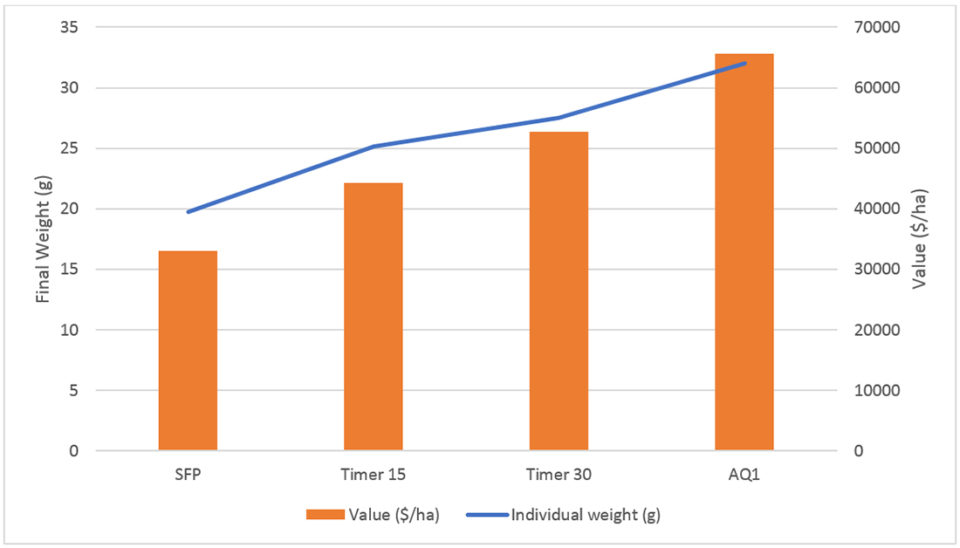

Results after 13 weeks are presented in Figs. 2 and 3. The final individual weights of 19.7, 25.1, 27.5, and 32.0 grams (SFP, Timer 15, Timer 30, and AQ1, respectively) were significantly different for all treatments. The differences in final weight resulted in significantly higher yield and value of shrimp (Fig. 3). There was a significant increase in the feed input, 5,250 kg/ha in SFP with only two feedings per day to that of the AQ1, which self-managed feed inputs delivering 9,002 kg/ha. However, no significant differences were seen in survival 58.5 to 63.9, FCR 1.07 to 1.24 or price of feed/kg shrimp $1.04 to $1.20.

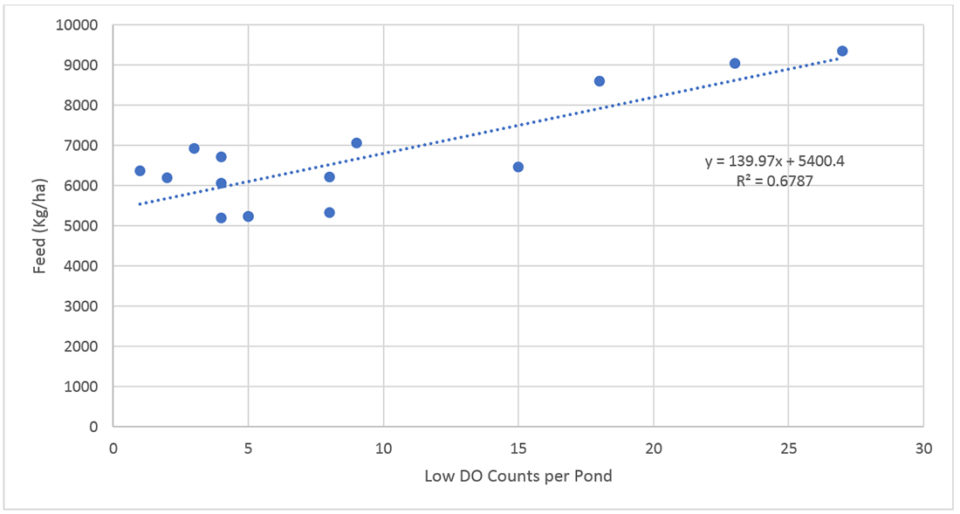

There were no significant differences in water quality with the exception of DO. The occurrence of low DO (<3.0mg/L), was significantly higher for the AQ1 treatment as compared to the other treatments as feed inputs were almost twice that of the SFP. Fig. 4 shows the trend of low morning DO counts increasing with the total feed inputs which corresponds to the oxidative requirements of the feed.

The results demonstrated that increasing the number of daily feedings, in conjunction with automated feeding systems, can allow for increased feed inputs and consequently increase intake and growth resulting in increased production and value of L. vannamei. Based on our observations, as well as results at numerous commercial operations, the use of on demand feeding allows for an increase in feed inputs without overfeeding.

As the AQ1 system manages feed input instantaneously it responds to the feeding activity of the shrimp without wasting feed. Thus, improving both feed conversion and growth. The combined increase in feed inputs, improved FCR and enhanced growth all lead to improvements in economic efficiency which in turn should easily offsets the costs of the equipment.

Given that these technologies all lead to increased feed inputs one also has to consider the effects on water quality and production characteristics. Higher feed input resulted in a need for increased oxidation or higher levels of aeration. At our facility, aeration capacity is fixed so as feed inputs were increased so was the number of days for which DO was below 3 ppt (Fig. 4) and the time required for aeration. This demonstrates the need to consider the interaction of feed management and water quality, which of course is the initial source of all pollutants that will need to be managed.

Other consideration must be given to growth, days to harvest and shrimp size at harvest. In our, system we were able to reduce our days to market as growth rates were increased almost two folds. In fact, if we chose to harvest at 20 grams we could run a 60-day production cycle as opposed to a 90-day cycle to around 35 grams. Overall, moving to a new technology means that one has to not only adopt the technology, but one has to be willing to adjust operational procedures to accommodate changes in the operation.

Perspectives

Results of our study show that increases in feed input, application of adaptive technology, and training of people to maintain the feeding system must all be considered when implementing new technologies. Based on our results with automated systems, we will soon abandon hand feeding and adjust our procedures to incorporate automated systems as they have shown to be far more efficient system.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Allen Davis, Ph.D.

Professor

School of Fisheries and Aquatic Sciences

Auburn University, AL, 36849 USA[117,100,101,46,110,114,117,98,117,97,64,97,100,115,105,118,97,100]

-

Carter Ullman, M.S.

Graduate Research Assistant

School of Fisheries and Aquatic Sciences

Auburn University, AL, 36849 USA -

Melanie Rhodes, M.S.

Research Associate

School of Fisheries and Aquatic Sciences

Auburn University, AL, 36849 USA -

Romi Novriadi

Graduate Research Assistant

School of Fisheries and Aquatic Sciences

Auburn University, AL, 36849 USA -

Anneleen Swanepoel

Graduate Research Assistant

School of Fisheries and Aquatic Sciences

Auburn University, AL, 36849 USA

Tagged With

Related Posts

Aquafeeds

Demand feeding through automatic dispensing systems

Studies showed that the demand feeding system for farmed shrimp – based on multi-rations and combined with sound detection – can be used to distribute the correct dosage of aquafeed with high nutritional density.

Innovation & Investment

Rise of the machines: Aquaculture’s robotic revolution

Technological advances are revolutionizing aquaculture. From airborne inspection tools to underwater drones, innovative robotics and automation technology are unveiling a brave new world of futuristic farming.

Innovation & Investment

Eight digital technologies disrupting aquaculture

Eight digital technologies are disrupting aquaculture and having a profound impact on the way business operates – even displacing some established ones.

Aquafeeds

Feed trays: The good, the bad, the ugly

Feed trays are typically used to avoid overfeeding in aquaculture production systems. They are sometimes used to deliver 100 percent of the feed that is fed, and other times a small number of trays are used as a guide to evaluate broadcast feeding techniques.