Comparing bioavailability for Pacific white shrimp

Nutrient and organic enrichment of various coastal aquatic ecosystems has been linked with the discharge of aquaculture effluents into these areas. Various approaches have been used to treat aquaculture wastewater, including settling basins, artificial substrates, constructed wetlands, filtration with bivalves, reduction of water discharge, and more recently through microbial-based, low or zero water exchange rearing systems.

Additionally, aquaculture wastewater has been used to irrigate agricultural crops, fertilization of halophytes, and for the production of microbial bioflocs used as a dietary food source. Biofloc particles have been reported to have 120 to 490 g/kg of crude protein, and usually have lipid levels below 20 g/kg. Various studies have reported that microbial flocs can be used as a nutrient source for marine shrimp and other farmed species.

The production of microbial flocs from aquaculture wastewater has been demonstrated previously by various researchers. Biofloc produced using wastewater from aquaculture operations can be converted into dry biomass, which can then be a potential source of protein in shrimp diets and also reduce effluent discharges and their impact on receiving waters.

This is a summary of our research [originally published in R. Bras. Zootec., 44(8):269-275, 2015] to compare the bioavailability of crude protein and lipid from biofloc meals produced with an activated sludge system using two water sources: wastewater from shrimp experimental culture and, artificially, using clean seawater.

Study setup

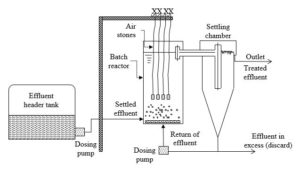

In our study, we used two activated sludge systems to generate microbial flocs using 1. Wastewater from an experimental shrimp nursery system (6 tanks, each 3-m3, wastewater biofloc); and 2. Seawater from a nearby estuary, sand-filtered and disinfected (clean seawater biofloc). The system was composed of two laboratory-scale activated sludge systems (Figure 1) that were used to produce biofloc samples. Please refer to the original publication or contact the first author for a detailed description of the sludge systems, their operation, production of sludge and biofloc samples, chemical analyses and apparent digestibility of biofloc meals produced, calculations of digestibility of crude protein and lipid of each individual ingredient under evaluation, preparation of test diets, and results of feeding trials with Pacific white shrimp (Litopenaeus vannamei), as well as the statistical analyses used in this study.

Results

Over the course of 81 days, 1,965 and 1,145 grams of dried biofloc meal (wastewater and clean seawater types, respectively) were collected and both types of biofloc meals had high ash (649.2-591.0 g/kg) and low crude protein (95.9-137.3 g/kg) contents. Our results differ from other studies using microbial flocs produced in batch reactors using effluent from tilapia culture and sugar as a culture medium. Other researchers determined crude protein, ash, lipid and crude fiber contents of 490±15, 134±6, 11.3±0.9, and 126±1 g/kg, respectively. Additional work is needed to reduce the amount of ash in the samples and thus concentrate the protein portion of the samples.

Sabry-Neto, Table 1

| Parameter | Wastewater | Clean seawater |

|---|---|---|

| Dried matter | 928.6 | 913.2 |

| Crude protein | 95.9 | 137.3 |

| Fat | 7.2 | 9.1 |

| Fiber | < 5 | < 5 |

| Ash | 649.2 | 591.0 |

| Calcium | 23.5 | 21.1 |

| Total phosphorous | 10.1 | 9.3 |

Proximate content (g/kg, dry matter basis)/Biofloc

Ash – consistently present in ingredients used to manufacture aquafeeds – has limited nutritional value (depending on its nature and origin) because fish and shrimp do not digest it. Meals produced from waste obtained in the slaughtering of terrestrial animals or from fish processing often have high levels of ash. However, ash values seldom exceed 250 g/kg, while the protein content may be higher than 400 g/kg (on dry matter basis).

The crude protein content in the biofloc meal produced from clean seawater was better than the one from the wastewater biofloc meal, which could have been caused by application of urea during the start-up phase of the biofloc produced using clean seawater. Based on our preliminary chemical analyses (high levels of ash and low protein content), neither type of bioflocs produced in our study would be considered suitable as an ingredient for shrimp aquafeeds. However, other studies have effectively used biofloc meal in L. vannamei diets as a source of protein.

In our study, the shrimp had a biomass gain of 37.1±1.8 g/tank and a final survival of 93.2±0.8% and (P>0.05, ANOVA). There was a statistically significant difference in final shrimp body weight, mostly between dietary treatments REF and BFL-C (P<0.05). Bioflocs contain low lipid levels and are poor in highly unsaturated fatty acids, such as EPA (eicosapentaenoic, 20:5n-3) and DHA (docosahexaenoic, 22:6n-3), which are essential nutrients, with a major role in penaeid shrimp nutrition.

The low ADC for crude protein observed for some of the diets tested reflect the bioavailability of the ingredients evaluated. The ADC of crude protein in the biofloc meal produced from wastewater (BFL-W), from clean seawater (BFL-C), and for the fish waste meal (NEG) were 26.0, 25.7, and 64.1 percent, respectively. Similarly, the lipid ADC were 78.9, 67.9, and 85.8 percent, respectively. The ADC of crude protein in ingredients used in shrimp diets generally fluctuate between 58 and 97 percent; these include soybean meal (89 to 97 percent); soy protein concentrate (93 percent); corn gluten meal (59 percent); blood meal (ADC = 66 to 71 percent); canola meal (80 percent); cottonseed meal (83 percent); shrimp meal (58 percent); anchovy meal (83 to 89 percent), krill meal (81 percent), meat and bone meal (60 to 88 percent), and poultry by-product meal (79 percent). Ingredients with crude protein ADC below 50 percent are not considered adequate as protein sources in shrimp aquafeeds. In our study, we determined that both types of biofloc meals had very poor digestibility for crude protein lower than the negative control (NEG).

Sabry-Neto, Table 2

| Nutrient/ADC | REF | BFL-W | BFL-C | NEG |

|---|---|---|---|---|

| Crude protein (g/kg) | 413 | 331 | 342 | 489 |

| ADC diet (%) | 80.9 | 75.0 | 73.1 | 74.7 |

| ADC ingredient (%) | – | 26.0 | 25.7 | 64.1 |

| Fat (g/kg) | 85.7 | 49.1 | 50.9 | 97.9 |

| ADC diet (%) | 93.8 | 93.1 | 92.6 | 90.2 |

| ADC ingredient (%) | – | 78.9 | 67.9 | 85.8 |

Apparent digestibility coefficient (%, dry matter basis)/Diet

As yet, no ADC values for crude protein and lipid have been reported in the literature for bioflocs. However, other researchers have successfully replaced fish meal and soybean meal in L. vannamei feed with bioflocs produced from tilapia farming effluents. Others have realized higher shrimp growth rates (1.44 to 1.66 g/week) feeding diets with bioflocs vs. diets without bioflocs; also, that shrimp fed diets containing 20 percent of intact biofloc for eight weeks reached the highest growth rates, even when compared with a commercial control.

We observed a higher final shrimp body weight when the test shrimp were fed a diet containing 30 percent of the bioflocs produced from clean seawater and 70 percent of the reference diet. This observation suggests that bioflocs may have had a growth-promoting effect on Pacific white shrimp, and that this effect is not directly related to the protein in the bioflocs, but to other nutrients, possibly macro- (calcium, phosphorus, potassium, and magnesium) and/or micro-minerals (copper, iron, manganese, and zinc). But these results must be confirmed by a longer rearing period (typically 10 weeks), and further studies are needed with bioflocs generated from aquaculture wastewater to elucidate what nutrients may have enhanced shrimp growth.

Perspectives

Bioflocs produced through an activated sludge system from wastewater from shrimp farming activities or from clean seawater have a low protein content available for juvenile L. vannamei. However, the low levels of lipid present proved to be highly available for the shrimp. Biofloc meals are characterized by a high mineral content. The dietary inclusion of biofloc meals appears to have a growth-promoting effect in Pacific white shrimp, which could be associated with trace minerals or other nutrients that were not identified in this study.

References available from senior author.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Dr. Hassan Sabry-Neto

Universidade Federal do Ceará

Instituto de Ciências do Mar

Fortaleza, CE, Brasil -

Dr. Sandra Tédde-Santaella

Universidade Federal do Ceará

Instituto de Ciências do Mar

Fortaleza, CE, Brasil -

Alberto Jorge Pinto Nunes, Ph.D.

Universidade Federal do Ceará

Instituto de Ciências do Mar

Fortaleza, CE, Brasil

[114,98,46,99,102,117,64,115,101,110,117,110,46,111,116,114,101,98,108,97]

Tagged With

Related Posts

Intelligence

Biofloc technology production promising in temperate zones

A study was conducted to assess the feasibility to grow Channel catfish (Ictalurus punctatus) in an outdoor biofloc system during winter in a temperate zone. High biomasses of market-size channel catfish were successfully maintained through the winter with high survival and in good condition in both treatments.

Aquafeeds

Biofloc consumption by Pacific white shrimp postlarvae

The stable isotopes technique with δ13C and δ15N can be used to determine the relevance of different food sources to shrimp feeding during the pre-nursery phase of Litopenaeus vannamei culture. During this trial, different types of commercial feed, microalgae, Artemia sp. nauplii and bioflocs were used as food sources.

Health & Welfare

Aquamimicry: A revolutionary concept for shrimp farming

Aquamimicry simulates natural, estuarine production conditions by creating zooplankton blooms as supplemental nutrition to the cultured shrimp, and beneficial bacteria to maintain water quality. Better-quality shrimp can be produced at lower cost and in a more sustainable manner.

Health & Welfare

Evaluating biofloc technology for intensive culture of fathead minnows

A study tested the use of biofloc technology to improve the productivity of the fathead minnow (Pimephales promelas) a commercially important baitfish in North America.