New aquaculture industry in Chile?

The aquaculture industry is well developed in Chile, with Atlantic salmon, Coho salmon and rainbow trout the main species cultured in the cold sea waters of the country’s southern region. However, further efforts have been directed toward transferring the farming technology for other fish species. Chile is a very long country whose 5,000-km coastline offers many different scenarios, from the glaciers and fjords in the extreme south to the driest desert in the world in the northern part of the country.

As part of the industry diversification, a unique pilot project supported by E-CL S.A., northern Chile’s biggest power-generating company, and the Undersecretary of Fisheries and Aquaculture is raising cobia in a recirculating aquaculture system in the desert environment of northern Chile.

The concept is to start and prove technology with cobia, which are demanding in terms of environmental and nutritional requirements, before moving to produce other commercially important species, such as flounder.

Cobia In Chile?

Cobia, Rachycentron canadum, is a warmwater fish, so the northern coast is the only area in Chile suitable for culture of the species. The sea temperature does not fit all the needs for its growth and production, however. The authors therefore proposed an innovative project to the thermoelectric company E-CL, which belongs to GDF Suez, given that its process of electric production needs water to cool the boilers. Cooling water pumped from the sea shore gains temperature and becomes more suitable for aquaculture purposes.

After three years of preliminary project work and finally obtaining the necessary permits, the authors started the construction of the experimental, land-based fish farm. Consisting of nine recirculating aquaculture systems (RAS), the project allowed them to experiment with different temperatures and salinities to establish the best culture conditions for cobia in northern Chile.

Alternative species

The company that started the farm, Agroaqua Ltda., has been in the salmon-farming industry for 23 years, including the designing, building and operating of commercial RAS systems for the last 10 years. To diversify into producing cobia, the company decided to seek assistance from the University of Miami Experimental Hatchery in Miami, Florida, USA, which is well-known for having the most advanced technologies in the world for production of cobia and other marine species. This was a crucial step toward the successful development of the operation.

RAS systems

Each of the RAS systems consists of four 8-m3 tanks: one mounted high as a biofilter, two on the ground to hold the fish and one tank underground for use as a mechanical filter. Water is exchanged twice hourly with 98 percent recirculation.

A main idea behind the design and distribution of the nine RAS systems was to have a 3-x-3 matrix that allowed combinations of three different temperatures and three different salinities. E-CL provides three sources of water: freshwater with no salt, normal “cold” seawater and warm seawater.

First experiences

Cobia eggs and larvae were shipped from Miami to Mejillones in the Atacama Desert in northern Chile in three batches. The first arrived October 17, 2012; the second arrived December 24, 2012; and the last batch came June 26.

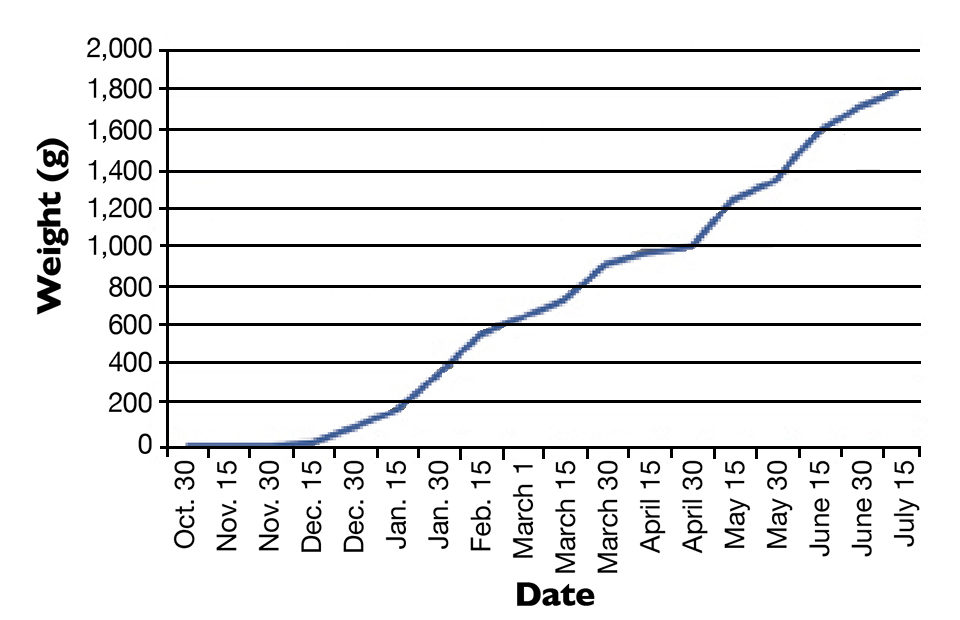

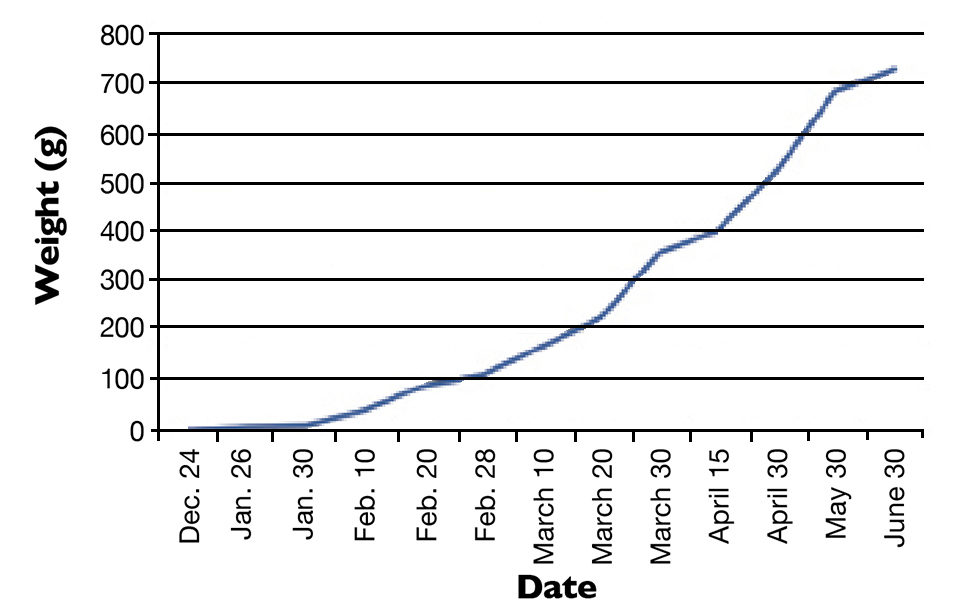

Figures 1 and 2 show the growth performance of cobia from batches 1 and 2 cultured at the RAS facility through June, starting in October and December 2012, respectively. Animals reached average weights of over 1.8 kg and 700 g with excellent survivals averaging 90 percent after larvae stage.

With such good results for the project – a first for cobia raised in an RAS in a desert environment – E-CL is motivated to continue its financing into the scaling analysis. All involved are committed to establishing development that generates employment and healthy protein.

Fishermen looking for a new job horizon have been trained, and their participation has been excellent. The cultivated fish have never been medicated with antibiotics or chemicals, and the farm management wants to continue practicing sustainable aquaculture.

Conservation, recycling

The project strives to minimize waste by recycling as much as possible. Everything is raw material for other processes. The current focus is on the use of effluent water to irrigate saltwort or sea asparagus, Salicornia – succulent, salt-tolerant plants that grow on beaches and in marshes and mangrove areas. An initial perimeter of the plants has been established, with plans to expand to a larger area watered with fish effluents treated with established disinfection protocols.

Worms are also being used to filter organic matter from fish wastes. Effluents from fish tanks run through a system of worm beds. The resulting compost product is incorporated into the Salicornia-producing areas to promote plant growth.

(Editor’s Note: This article was originally published in the September/October 2013 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Daniel Nieto Díaz-Muñoz, Med. Vet.

Cobia SpA

P. O. Box 614

Antofagasta, Chile[109,111,99,46,97,109,97,99,97,116,97,111,116,114,101,105,115,101,100,97,105,98,111,99,64,111,116,101,105,110,108,101,105,110,97,100]

Tagged With

Related Posts

Innovation & Investment

AlgaPrime, ingrediente de alimentos acuícolas, gana el Premio GAA a la Innovación

Una proliferación de ingredientes alternativos ha permitido a la acuacultura extender los recursos naturales de los que depende. AlgaPrime, con altos niveles de DHA, el ácido graso omega-3 de cadena larga, está siendo reconocido como una innovación que cambia el juego para los alimentos acuícolas.

Intelligence

Bahamas venture focuses on grouper, other high-value marine fish

A new venture under development in the Bahamas will capitalize on Tropic Seafood’s established logistics and infrastructure to diversify its operations from processing and selling wild fisheries products to include the culture of grouper and other marine fish.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Intelligence

Canned mahimahi and more bits from Boston

Global Aquaculture Advocate Editor James Wright is covering Seafood Expo North America in Boston, Mass., USA. Check back periodically for updates.