Melanosis, or blackspot, can be presented with antioxidant treatments like sodium metabisulfite

Harvest

In both types of harvesting, manual or mechanized, personnel involved must always be aware of time and temperature. The shrimp must be chilled as soon as possible when they are removed from the pond, and this is accomplished by dipping the shrimp in a tank with water and ice. After removing the shrimp from this tank, the shrimp can be placed in either crates (30-40 L) or bins (500-1000 L); both work properly if adequate procedures are followed.

If processing and transporting the harvested shrimp in crates, this usually involves immersing the crates with shrimp in tanks containing a mixture of water and ice. If using bins to process and transport, the bins usually are already partially filled with the ice/water mixture or with slurry ice. At this stage it is important to avoid mistakes that can compromise the quality of the shrimp.

The temperature of the ice/water mixture and the shrimp must be controlled with a thermometer, not by hand feeling. When the atmospheric temperature is higher than 20 degrees-C, dipping one’s hand in a 15 degrees-C solution can feel like it is really chilled, but 15 degrees-C is not chilled. The temperature at the core of the shrimp must be lowered as quickly as possible to below 2-3 degrees-C to quickly slow all biochemical reactions that will cause irreparable tissue degradation.

At ambient temperature, a water and ice mix will have a temperature of only 9-15 degrees-C, which is not cold enough to drop below 3 degrees-C the temperature of a shrimp harvested from the pond at between 20 and 28 degrees-C. Lack of control of temperatures inevitably leads to the “red head” phenomena in shrimp that will downgrade product quality.

An easy and inexpensive solution is to add regular salt (sodium chloride) to the solution of ice and water. This mixture of water, ice and salt used for chilling the shrimp after their harvest can reach temperatures lower than -5 to -8 degrees-C. Dipping the 25 degrees-C shrimp in this mixture can lower their temperature to 1-2 degrees-C in a few minutes . This use of salt results in a significant reduction of ice consumption during the harvest, with a more efficient way to reach the desired lower temperatures of the product.

Effect of salt to decrease ice temperature

Sodium chloride and water form a eutectic mixture, which describes the mixture of two or more substances that will bring down the freezing point – called the eutectic point – of any mixture of its components. The dissolution of salt and ice melting requires energy: the dissolution of 1 gram of salt requires 66 Joules, and this energy will be extracted from the mixture, and this explain why the temperature of the mixture goes down.

Sodium chloride is formed by the regular assembly of negatively charged chloride ions and positively charged sodium ions. At a microscopic level, when a grain of salt (which contains billions of molecules) comes into contact with the surface of ice, the atoms of solid water and the ions of solid salt rearrange to form a new phase (H2O × NaCl) and this is called an eutectic, which melts and produces a thin film of liquid water on the surface of the ice (solid water). The process then propagates throughout the rest of the ice, as the ions in the liquid film progressively contact the rest of the ice still present, slowly transforming it into salty liquid water.

To dissociate and extract individual molecules of water ice, the salt molecules need energy that is removed from the water molecules that form the ice crystals, and so its temperature drops sharply. This is an endothermic reaction that “produces cold.” In fact, the salt takes the heat from the ice that is surrounding it. Therefore, when the salt melts the ice, it makes it much cooler, contrary to what one might think. In this reaction, the temperature of the mixture can go down to minus-21 degrees-C.

For harvests using crates and tanks on site, it is necessary to follow the evolution of the temperature of the bath to maintain its temperature by adding ice and salt as needed. In this regard, we must consider that most of the salt is consumed because the ice is melting due to the warming effect caused by adding newly harvested shrimp that is warmer. To maintain the same salinity in the cooling tank at the beginning of the harvest and to keep the correct temperatures, the same proportion of salt must be added after each ice addition.

A common approach is to use 600 liters of mixed water and ice, or slurry ice (50 percent ice and 50 percent water) for every 400 kg of shrimp. The quantity of salt should be previously determined empirically by doing tests at the farm and under the conditions that will be prevalent during the harvest. The quantities would vary in relation to water composition, temperature of the harvested shrimp and their size, and other variables. Therefore, the numbers above are a general guide derived from experience. This is an important step, which should be done carefully. If not enough salt, the mixture is not efficient. But too much salt and the temperature of the shrimp could be too low (below-20°C), which would be undesirable.

For this process to be efficient, it is absolutely necessary to mix well, slowly and constantly, the shrimp in this mixture until the desired temperature is reached. If the mixed water/ice/slurry ice/shrimp contents of a bin or a crate are not well mixed, the shrimp in contact with the chilled water will be cold but the shrimp not in contact will remain warmer even if there appears to be plenty of ice in the bin.

Many shrimp farmers are often afraid to shake well the shrimp in the bins or crates because they fear that this could physically damage them, especially breaking the head. Live shrimp are stronger than we think; however, they become more fragile when they have been dead for some time. Mixing them vigorously when they have just been collected from the pond will not damage them except if they are crushed against the wall of the container, which should absolutely be avoided (employee training). If using crates, the shrimp should be gently mixed by hand; if using bins, the best mixing tool is a snow shovel made of plastic.

This is a physically demanding job and the person in charge must rotate personnel so the process is effective, so there must be enough workers present throughout the entire duration of the harvest.

Once the desired temperature is reached in the bin, it can be drained as needed, because otherwise the weight of shrimp inside could be affected by osmosis. If the salinity of the slurry ice is higher than 26 ppt (this is the intracellular salinity of the shrimp body), the shrimp could lose intracellular water and this would be lost product weight.

If the slurry salinity is lower than 26 ppt, the cells of the shrimp would absorb water and gain weight. The latter will affect the texture of the shrimp flesh, and this extra water will be lost immediately when the shrimp are cooked. In any case, consumers will not be pleased and this would negatively impact your product reputation.

Monitoring controls of shrimp quality and temperature must be carried out regularly throughout the entire harvest time. This will help identify any quality changes, for example in the case of massive molting in the pond, and to make the appropriate decision to suspend or resume the harvest. A good guideline is to carry out these controls for every 500 kg of harvested shrimp.

Antioxidant treatment to prevent melanosis

When crustaceans die, oxidation and enzymatic reactions will induce the blackening of the animals, and this is called melanosis or blackspot. It is a harmless discoloration or darkening that happens in the head, tail, swimming legs and other parts of the shrimp body. This is a well-known phenomenon that has no impact on product taste and is not an indication of bacterial spoilage of the product, but the appearance can be repulsive for consumers. If necessary, melanosis can be prevented using anti-oxidant products.

The most used and efficient product to prevent melanosis is sodium metabisulfite (SMBS): the sulfite SO2 in SMBS captures oxygen and become SO42-. However, its effects are temporary and when all the SO2 is transformed to SO42-, the melanosis resumes.

The accumulation of SO42- will lower the pH of the shrimp and at a certain level could affect its taste. However, nowadays SMBS is the most efficient product to control melanosis, especially for shrimp intended for the industrial cooking market in Europe. It may have some undesirable side effects, particularly an allergen that may cause severe illness in some susceptible people. It is, however, a product widely used in the food industry, especially in wine and beer manufacturing. For other shrimp markets, there are other antioxidants that can be used like citrus extract, rosemary extract and others that are less efficient to prevent melanosis. In my opinion, research is needed to find other products to replace SMBS, but currently it is the only efficient and easy to use one.

The traditional SMBS treatment involved taking the already chilled shrimp and dipping them in a solution of SMBS (7-8 percent depending on the protocol used) during several minutes (7-10 minutes depending on the protocol used). The problem with this method was how to properly control the real SMBS concentration in the bath. As for the salt in the chilling bath, the SMBS is diluted by the addition of ice, which could also be reduced by adding salt, as it help to keep the temperature down, and farmers were routinely adding SMBS to compensate for this dilution.

But SMBS is soluble in water with temperatures higher than 25 degrees-C. At lower temperatures, a large portion of the crystals are in suspension and are not efficient. So it is necessary to previously dilute the SMBS in water with a temperature higher than 25 degrees-C before adding it in the treatment tank. Until a few years ago this was not too important because regulations were light, but fortunately stricter regulations are now in place, and any product batch with excessive residual concentrations in the shrimp flesh is refused.

A few years ago, when harvesting in bins became more popular, the procedure was to add a small quantity of SMBS to the bin with the slurry ice during a longer time, to reach an adequate residual concentration of SMBS. This procedure avoided using additional SMBS but required maintaining the shrimp in the treatment water for a longer time, which as mentioned before could affect the flesh texture because of osmosis.

However, as soon as personnel stop mixing the shrimp in the bin, sedimentation occurs and the ice floats to the surface. As this ice melts it dilutes the SMBS at the surface of the water in the bin. This can create a concentration gradient of SMBS in the shrimp, with a higher concentration at the bottom of the bin; this gradient could be significant and make the treatment non homogenous.

The best approach is to chill the shrimp at the farm during the harvest, and drain the container (bin) as soon as the shrimp temperature goes below 2 degrees-C. If the shrimp reach a temperature lower than 2 degrees-C, they can be maintained without risk of melanosis development during more than 10 hours.

But the control of the temperature is a key factor. Then the shrimp can be transported to the packing plant and the SMBS treatment can be applied there. It is very important to reiterate that the harvested shrimp should be rapidly chilled (below 3 degrees-C) immediately after harvest when they are still alive, and should be kept chilled during the entire process. This is an essential condition to prevent the early development of melanosis and to obtain a resulting, high-quality product.

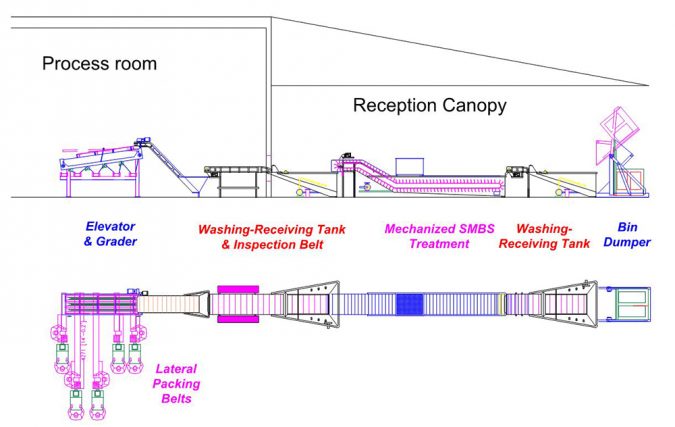

The SMBS treatment must not be applied inside the packing plant building but outside in a well-shaded and ventilated area to prevent any potential negative effects of SMBS vapor on the personnel and the equipment. An automated/mechanized treatment process, without the use of ice, can be implemented and the temperature of the SMBS solution can be controlled using the plant’s cold primary circuit. Not having to use ice significantly reduces the need for more SMBS additions to maintain the desired concentrations. The automated SMBS treatment unit can be combined directly with the inspection belt and the grader (Fig. 3).

For a long time, experts believed that for an efficient SMBS treatment the shrimp had to be treated while still alive. This is incorrect, as it has been demonstrated that the residual sulfite concentration is much more homogeneous in the shrimp flesh when the treated animals are already dead and chilled.

As for chilling them, another absolute requirement to have a uniform residual concentration of SMBS is to routinely mix and homogenize the shrimp treatment tank. Applying the SMBS treatment at the plant avoids the undesirable discharging of the SMBS solution anywhere within the farm, and instead uses the plant’s wastewater system to treat this water.

Transporting shrimp to the packing plant

If harvested shrimp are handled in crates, they must be transferred in at least an insulated truck – or preferably a refrigerated one – as soon as they have been chilled and, eventually, treated with SMBS. If bins are used, it is essential to avoid opening them unnecessarily, to better preserve the cold temperature as much as possible.

When filling a bin, it must be opened just for the time required to put the shrimp in and then be closed immediately after completely filling the bin. It will be reopened as needed when it is necessary to mix its contents to homogenize the temperature and/or concentration of SMBS, but the cover should be replaced immediately after completing the operation. Once the harvest is over, the shrimp must be shipped as soon as possible to the packing plant.

Sanitation considerations during the harvest

All personnel working in the harvest area must wear appropriate, clean clothes and use stringent hygiene and sanitation procedures that should be clearly specified in the harvesting SOPs. It is particularly important that they wash their hands, especially before touching any harvesting equipment or any shrimp. All equipment used in harvesting and pond-side processing must be thoroughly washed and disinfected before and after harvesting.

The water used for chilling the shrimp and/or for the SMBS treatment must comply with all required standards for microbiological quality and food biosafety. The ice used for the harvest and in pond-side or farm processing must be made with potable water complying with the pertinent international microbiological norms.

References available from author.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Hervé Lucien-Brun

Aquaculture & Qualite

9, rue Poupinel, F-78730

Saint Arnoult en Yvelines, France[109,111,99,46,108,105,97,109,103,64,98,108,101,118,114,101,104]

Related Posts

Health & Welfare

New management tools for EHP in penaeid shrimp

Authors examined the histological features from shrimp infected with the emerging microsporidian parasite Enterocytozoon hepatopenaei (EHP). A PCR assay method was used to detected in hepatopancreatic tissue, feces and water sampled from infected shrimp tanks, and in some samples of Artemia biomass.

Aquafeeds

Testing shrimp growth in different biofloc systems

A study conducted with juvenile shrimp (Litopenaeus vannamei) reared in experimental biofloc systems used four treatments. Results indicate that differences in management and carbohydrate source can lead to substantial disparity in system function and production.

Intelligence

We can grow better shrimp, and in better ways

The recent Central American Aquaculture Symposium in Choluteca, Honduras, brought together more than 600 participants to discuss industry issues and perspectives. The focus was shrimp diseases and their impacts on production, as well as practical alternatives to face these issues and move forward.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 1

Harvesting a crop of shrimp is a critical step for any shrimp farming venture. Several months of efforts and resources to properly raise a quality crop have already been invested, and this quality must be preserved. The decision to harvest involves consideration of various factors.