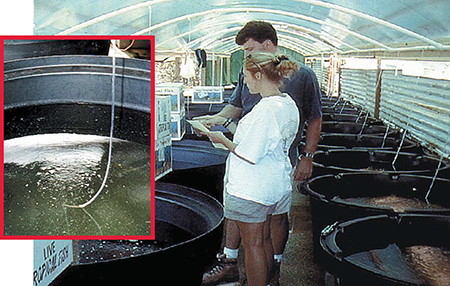

Expanding stock enhancement program releasing juveniles

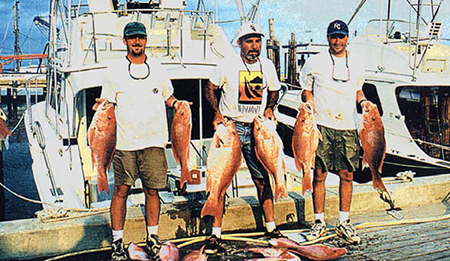

The red snapper (Lutjanus campechanus) is an offshore reef fish that is highly desirable as a recreational and commercial fish in the Gulf of Mexico. But because snappers remain in the vicinity of an underwater structure until the area is overfished, they can become depleted.

Overfishing and stock enhancement

Red snapper were recently designated as overfished in the Gulf of Mexico by the U.S. National Marine Fisheries Service. This created controversy among federal agencies, state agencies, and private individuals. Catch limits on the recreational fishery and quotas on the commercial fishery have only intensified the debate.

Red snapper was selected by the U.S. Gulf of Mexico Marine Stock Enhancement Program as the subject of a program to demonstrate a responsible approach to stock enhancement. At the Gulf Coast Research Lab in Ocean Springs, Mississippi, USA, red snapper have been successfully reared during the past three summers and released offshore for two years. During the first two years of the lab’s program, larvae were obtained with the assistance of the Alabama Department of Natural Resources. During the third year, larvae were produced at GCRL.

Maturation and spawning

Mature snapper can be caught by hook and line, transported to shore, and injected with human chorionic gonadotropin hormone to induce final maturation. Suitable fish are generally available between May and October. Even though a large female snapper can produce several million eggs, fish of 0.90- to 1.36-kg size are easier to handle, and therefore preferred subjects. Strip spawning and fertilization of these smaller snappers will produce 100,000 to 300,000 eggs per fish, 30 percent to 50 percent of which will hatch. The eggs are generally stripped 24 hours after hormone injection.

Hatching and early development

Buoyant, fertilized eggs are collected from the water surface and transferred to a hatching tank. Hatching generally occurs 24 hours after fertilization. Newly hatched larvae, about 2.2 mm long and transparent, consist of only a tail and a small, bulbous mass that will become the head.

They can be transported for up to 24 hours with minimal loss, and can be moved by gentle wet transfer in beakers or buckets. They cannot be pipetted or netted, so stocking is done on the basis of sub-sampling and estimation. By day 2, they develop pigmented eyes and a large head. By day 3, the small yolk reserve is exhausted, but they have a mouth and are ready to feed.

Attempts to rear the larvae have until recently been unsuccessful, due largely to feed problems. Previous researchers generally offered rotifers, the food of choice for larval fish culture, to snapper larvae as a first feed. More rotifers, better rotifers, and smaller rotifers were all tried without success. Oyster larvae were also tried, but the snapper larvae seldom survived more than five days.

Such results were discouraging, since it is now known that fair numbers of larvae can survive to day 5 without feeding, and some can live seven days without food. At GCRL, shaded culture tanks combined with a new diet of copepods to produce higher survival rates.

Larval culture system

At the Gulf Coast Research Lab, larvae are cultured in black tanks placed inside a shaded, open-sided greenhouse. One-day-old larvae are stocked 10 per liter into lightly aerated 30-ppt water in the tanks. Although a variety of containers and locations have been tried for rearing, the lab’s only successes have been achieved in these 200- or 1,000-liter tanks located in the outdoor greenhouse.

It is necessary to cover outdoor tanks to prevent rain from diluting and polluting the culture. In Mississippi, if a clear cover is placed over an outdoor tank during the summer, the temperature can reach 36 degrees-C, which is lethal for snapper larvae. Therefore, GCRL uses a shade cloth that blocks 85 percent of the sunlight and reduces temperature. Even with this shade, temperature still fluctuates between 24 and 32 degrees-C.

Natural water is pumped from Davis Bayou, off Biloxi Bay, filtered through a 10-micron filter bag, and adjusted with artificial sea salt to 32 ppt. The 200-liter tanks are filled to capacity to achieve proper water circulation. To increase the initial density of prey, the 1,000-liter tanks are initially filled with only 400 liters of water, but still stocked with 10,000 larvae. The water volume is increased after day 12 to the full 1,000 liters. Therefore, initial stocking in the 200-liter tanks is 10 per liter, while initial stocking for the 1,000-liter tanks is 25 per liter with a final density of per liter.

Larval production methods

During the first rearing trials at GCRL, larval survival was greatly reduced in tanks that were intensively managed by daily siphoning, recirculation, or water exchanges. It is possible that turbulence from aeration and other maintenance in the small tanks was responsible for the low survival. Therefore, GCRL modified the management to utilize very light aeration and no daily tank maintenance until at least day 12 for the production tanks.

After day 12, tanks are siphoned and water additions made. Care is taken to check salinity, as evaporation in the open greenhouse increases salinity in the tanks to 40 ppt over the first two weeks.

Starting at day 2, larvae are offered calanoid copepod nauplii produced in 100-square-meter tanks utilizing a brown-water culture method. Technicians attempt to keep prey densities at greater than 2.5 per milliliter with 5 milliliter preferred. The copepods are size selected, with the fraction from 23 to 68 meters offered initially.

The prey size is increased at day 5 to the 23- to 125-meter range, and at day 8 to 68 to 200 meters. During the first two years of GCRL’s program, enriched artemia nauplii were offered beginning at day 12. By day 14, the larvae were receiving artemia at a rate of 5 to 10 milliliter artemia were eliminated the third year. Fish fed exclusively on copepods were larger and survival was slightly higher.

Brown-water culture method

GCRL’s success in rearing red snapper larvae has been due to its ability to produce copepods in outdoor tanks. As early as 1979, the Gulf Coast Research lab developed a brown-water culture method for operation of an oyster hatchery. At that time, it was discovered that the brown water would also produce copepods. Twenty years later it seemed natural to retry that method in an attempt to produce a food that might be suitable for red snapper larvae.

The term “brown water” describes the natural color of the estuarine waters of Biloxi Bay (Mississippi, USA) after they are pumped through a filter bag into a lightly aerated tank. The brown water is sufficiently nutritious to support oyster larvae and copepods. No additional feed is applied and no fertilizers are used.

The copepod cultures are predominantly Acartia sp., or Pseudodiaptomus sp. Rotifers and other invertebrate larvae may be present but will seldom dominate. The brown water in the tanks will start to clear in two to three days, at which time 50 percent of the volume is replaced with new brown water. The original oyster hatchery used 4,000-liter tanks; however, it was obvious that not enough copepods could be produced in such small tanks, so 100-square-meter tanks were used for the red snapper.

When copepod production slows in a tank, the cause of the decline is usually an abundance of settled oysters, attached barnacles, tunicates, mussels, or free-swimming jellyfish. These may directly consume the copepods or compete for the food. The tanks can be drained and cleaned in a matter of several hours, refilled, and back in full production in three to five days. Unlike zooplankton ponds, these tanks can be more easily managed and normal zooplankton succession more rapidly controlled.

Brown-water production system

During 1998, copepods were produced in one 100-m2 tank and used to supply a variety of larval rearing tanks. Copepods were harvested from the tank by pumping water through a sieve and returning the water to the tank. Every few days, 50 percent of the water was exchanged with new brown water and food in this fraction was lost. Therefore, during the second year the exchanged water was harvested for copepods before being discharged. In addition, three more 100-square-meter tanks were constructed, allowing half the volume of two tanks to be harvested daily.

A submersible pump was used to transfer the water to a central location where a battery of 45-cm-diameter sieves was tended daily by several workers. An average of four million nauplii were harvested daily, with a maximum of six million. Construction of two additional production tanks, the centralization of sieving activities, and the use of larger sieves both increased production and reduced the labor required to produce copepods. An average of six million – with a maximum of 24 million – nauplii per day were harvested by one person operating the sieve station during this past year.

Larval mortality

Young red snapper larvae are transparent and difficult to see. However, by day 19, dead post-hatch larvae are obvious and it is possible to estimate mortalities. As a result, GCRL originally noted an apparent die-off that accounted for 50 percent of total mortality at days 19 to 21. This past year, larval tanks were sampled daily and inventoried at day 5. This data suggested that 50 percent to 70 percent of the larvae are actually lost in the first five days.

Transfer to nursery tanks

Fish are generally harvested from the hatchery tanks between days 21 and 25, and transferred to nursery tanks that receive a flow of water from a large recirculating reservoir. Large numbers of fish can be lost during transfer. In the first year, harvests using buckets and mesh nets resulted in fish immediately spiraling to the bottom of the tank and dying. The use of clear plastic nets seems to have reduced this stress response.

Artificial diets

Over a two-week period, fish are transitioned from live feed to artificial pellets. The juveniles readily accept a variety of fresh and artificial feeds. In the first year of GCRL’s program, however, juvenile fish fed chopped squid and cigar minnows showed signs of deformity and chronic mortality.

The fish were subsequently fed a pelleted diet developed for mahimahi (dolphinfish, Coryphaena hippurus) at the Oceanic Institute in Hawaii, USA, and the deformities and mortality ceased. During the past two years, juveniles fed the Mahi-Mahi diet have not exhibited problems.

Cannibalism

There can be a high loss of fish in the nursery due to aggression. Larger fish will attack and kill smaller fish, resulting in a population of very uniformly sized fish. The use of increased water flow, substrates, habitat, and continuous feeding has not lessened the problem.

Red snappers were first discovered in the Gulf in the mid-1800s by a Connecticut fisherman becalmed on his way from Tampa to New Orleans. The cook on the fisherman’s boat threw the table refuse overboard and “very soon many strange-looking red fish were seen in the water alongside.”

The fish – which snapped at anything, even a bare hook – became known as “snappers.” A commercial snapper fishery developed around Pensacola, Florida, USA, during the 1870s. Those boats fished the Tortugas grounds after their discovery in 1885. In the 1900s, the fleets fished off Campeche, Mexico, but still called Pensacola home. Today, red snapper is one of the more popular sports fishes, and the recreational catch can exceed the commercial catch.

Conclusion

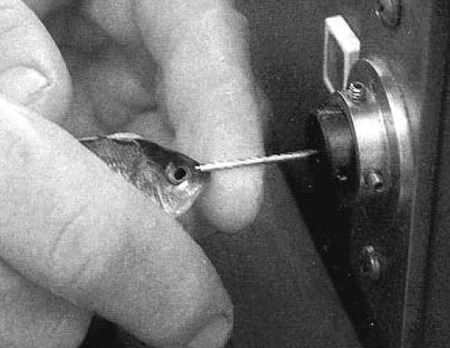

During the summers of 1998 to 2000, the numbers of red snapper successfully reared by the Gulf Coast Research Lab rose steadily from 3,574 to 5,564. During 1999 1,200 juvenile red snappers were tagged and released off the shore of Mississippi. This October, a release of 1,800 tagged juvenile snapper is planned for the Gulf waters of Mississippi, with another 900 fish to be released off the coast of Florida.

The goal of GCRL’s snapper program – supported in part by grant awards from the U.S. Department of Commerce, National Oceanic and Atmospheric Administration, and the National Marine Fisheries Service – is to produce sufficient numbers of fish to experimentally investigate the utility of offshore releases of a cultured marine fish. However, GCRL’s results should also contribute to starting the commercial aquaculture of red snapper. For this to become viable, however, hatchery production will have to increase.

At the Gulf Coast Research Lab, hatchery survival rates over the past three years (6.7 percent, 8.6 percent, and 12.5 percent) seem consistent with those of other newly cultured fish. Such numbers offer the opportunity for research to increase survival rates up to commercial levels. Success this year in producing fish in smaller tanks and in tanks located indoors offers further experimental opportunities to investigate the effects of environmental and nutritional factors on larval survival.

(Editor’s Note: This article was originally published in the October 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

John Ogle

Gulf Coast Research Lab

(GCRL-U.S.M.-IMS)

Ocean Springs, Mississippi, USA[117,100,101,46,109,115,117,64,101,108,103,111,46,110,104,111,106]

-

J.M. Lotz, Ph.D.

Gulf Coast Research Lab

(GCRL-U.S.M.-IMS)

Ocean Springs, Mississippi, USA

Tagged With

Related Posts

Health & Welfare

Advances in fish hatchery management

Advances in fish hatchery management – particularly in the areas of brood management and induced spawning – have helped establish aquaculture for multiple species.

Health & Welfare

Advances in intensive copepod production technology

Research at the Oceanic Institute has been successful in overcoming bottlenecks associated with rearing small-mouthed fish larvae by finding a suitable first feed. Early work on the calanoid copepod Parvocalanus crassirostris focused on parameters necessary for successful maintenance of stock cultures.

Intelligence

Aquaculture key to increasing seafood supplies to Arab states

Arab States have substantial natural resources to increase aquaculture production. Several types of systems are readily adaptable and can be implemented relatively quickly.

Intelligence

Canned mahimahi and more bits from Boston

Global Aquaculture Advocate Editor James Wright is covering Seafood Expo North America in Boston, Mass., USA. Check back periodically for updates.