Tools can help manufacturers control product density based on desired product characteristics

Aquaculture of an ever-increasing variety of aquatic species requires flexible feed manufacturing processes. Aquatic feeds can be broadly categorized based on their total fat content requirements as:

- low-fat diets (less than 12 percent fat)

- medium-fat diets (12 to 24 percent fat)

- high-fat diets (greater than 24 percent fat).

The diets in each category require different expansion ratios (bulk densities) to achieve the desired level of fat absorption and the desired floating/sinking characteristics.

Controlling feed density

Several process tools are available to control the feed density of extruded marine fish feeds, including:

- internal/external fat levels

- specific mechanical and thermal energy inputs

- extrusion moisture

- vented extruder barrel (with or without vacuum assist)

- extruder die value

- separate cooking and forming extruders.

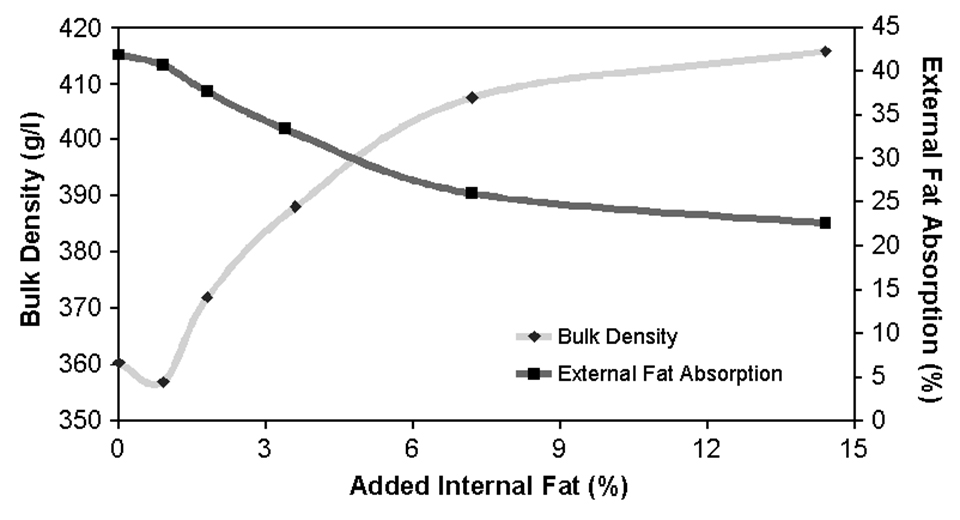

Internal/external fat levels

Nutritional requirements dictate the levels of fat required in aquatic feeds. The total levels can vary from 3 to 40 percent in diets. As the fat level increases, there is an expected increase in bulk density of the feed. For example, a diet containing 60 percent fishmeal, 24 percent soybean and 16 percent wheat grain was extruded at six internal fat levels. The internal fat level was adjusted by continuously injecting fish oil into the preconditioning phase of extrusion system at 0, 0.9, 1.8, 3.6, 7.2 and 14.4 percent levels. As the internal fat addition increased from 0 to 14.4 percent, bulk density of the extruded product increased and external fat absorption decreased (Fig. 1).

Specific mechanical, thermal energy inputs

Energy management is essential in controlling bulk density of extruded marine diets. A correlation exists between an extruder’s specific mechanical energy inputs and the bulk density of uncoated diet. As these energy inputs are increased, density will generally decrease.

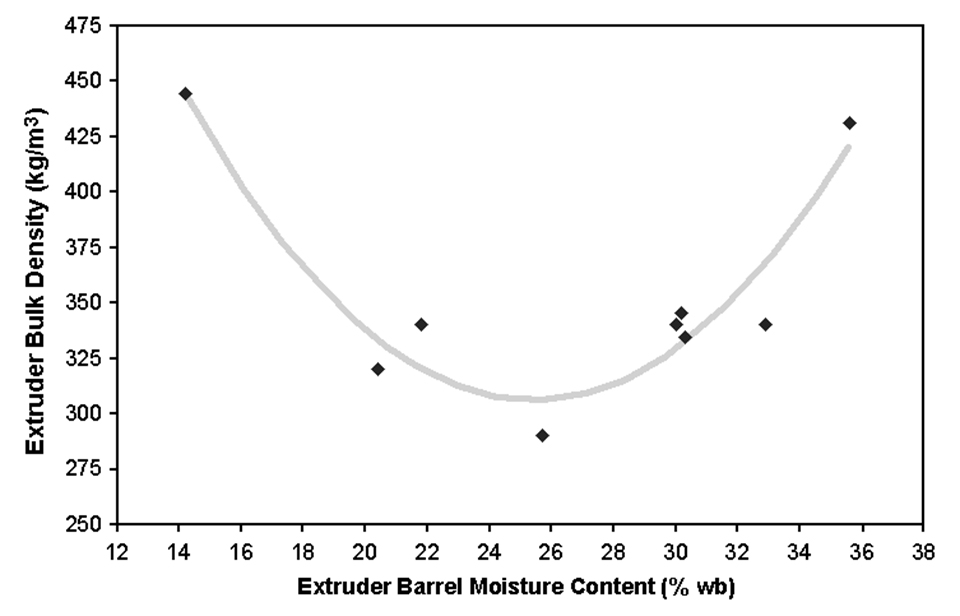

Extrusion moisture

Extrusion moisture is an important process variable for controlling final product characteristics, including bulk density. Extruded product bulk density first decreases and then increases as extrusion moisture decreases. (Fig. 2).

Vented extruder barrel

Extruder barrels can be configured to include an atmospheric vent to permit reduction in extrusion pressures to cool and densify the extrudate. Extruded feeds can be further densified by coupling a vacuum system to the vented barrel (Table 1). Vacuum levels of up to 50 kPa (15 inches of mercury) are employed to assist densification.

Rokey, Effect of vacuum-assisted extruder venting on pellet density, Table 1

| Pellet Size (mm) | Piece Density (g/ml) Without Vacuum | Piece Density (g/ml) With Vacuum |

|---|---|---|

| 6 | 0.87 | 1.23 |

| 20 | 0.92 | 1.14 |

| 25 | 1.12 | 1.19 |

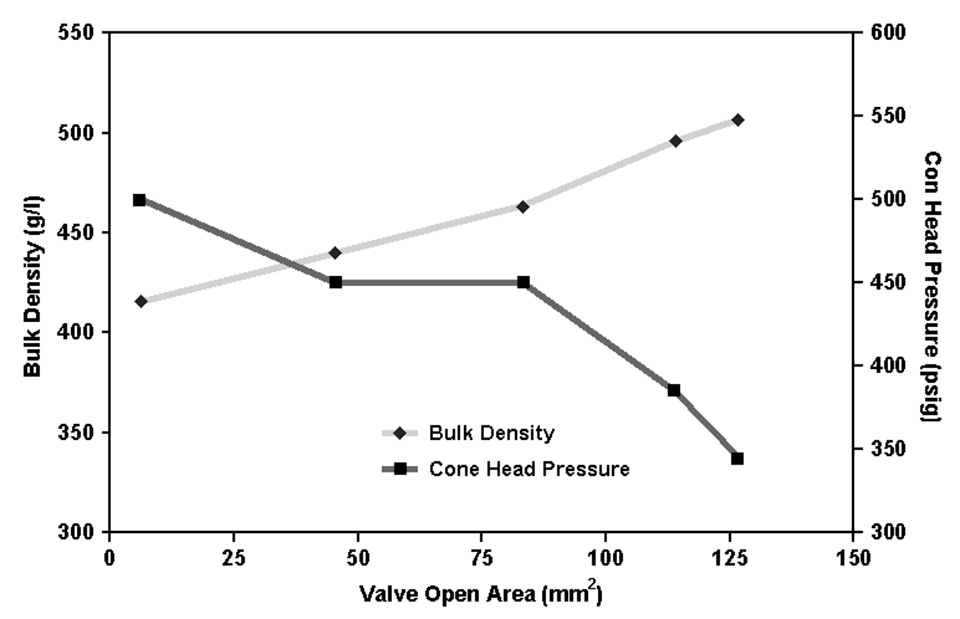

Extruder die valve

Extrusion pressure can be varied by adjusting the opening size of die flow-control valves. As the die valve open area is increased, extrusion pressures decrease and final product densities increase (Fig. 3).

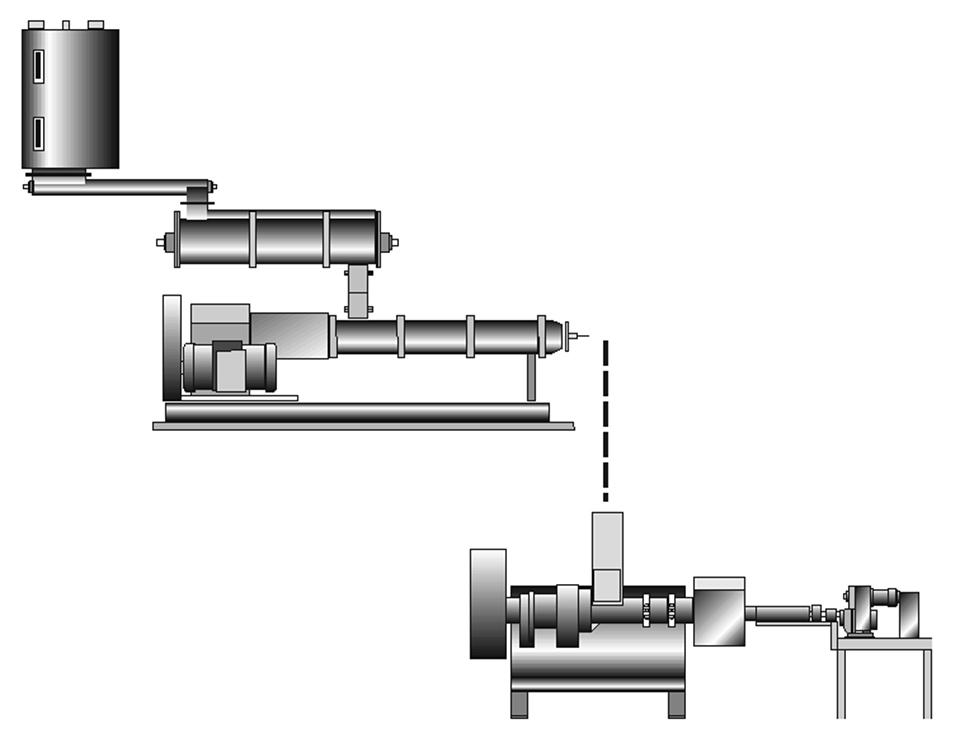

Individual cooking, forming extruders

Very high density aquatic feeds can be manufactured by processing diets through a cooking extruder followed by a separate forming extruder. This processing method requires extensive equipment installation, but the separate, secondary forming extruder cools and densifies the feed to a high degree (Table 2).

Rokey, Effectiveness of densification tools, Table 2

| Process Tool | Product Density Range (g) |

|---|---|

| Vented Barrel | 480-600 |

| Vented Barrel With Vacuum Assist | 480-720 |

| Cooking Extruder/Forming Extruder | 560-720 |

Conclusion

Various process tools are available to the manufacturers of marine fish feeds to control product density. The choice of which tool(s) to use depends upon the density required to achieve the desired product characteristics (floating/-sinking, fat absorption, pellet durability and others).

(Editor’s Note: This article was originally published in the October 2001 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Galen Rokey

Wenger Manufacturing Co.

714 Main Street

Sabetha, Kansas 66534-0130 USA[109,111,99,46,114,101,103,110,101,119,64,121,101,107,111,114,103]

Tagged With

Related Posts

Responsibility

A helping hand to lend: UK aquaculture seeks to broaden its horizons

Aquaculture is an essential contributor to the world food security challenge, and every stakeholder has a role to play in the sector’s evolution, delegates were told at the recent Aquaculture’s Global Outlook: Embracing Internationality seminar in Edinburgh, Scotland.

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Aquafeeds

A look at India’s fish feed industry

India's fish-farming industry makes limited use of modern feeds, providing potential for the feed sector to grow. Commercial feeds are predominantly used for pangasius farming, followed by a rising popularity in carp culture.

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.