Preparation of cooked, ready-to-eat shrimp requires greater control of processing parameters than freezing or raw product

Grupo Granjas Marinas (GGM) operates a 6,000-hectare shrimp farm in Honduras (Central America) and exports its products to highly discriminating retailers, who demand superlative product quality and safety. In 1998, GGM committed to a two-year investment plan to build a new shrimp cooking facility adjacent to its existing processing facility in Honduras, and to concurrently replace its existing refrigeration equipment. The following is a discussion of the considerations involved in designing a value-added shrimp processing facility.

The new cooking facility was designed to improve product quality by reducing overall product handling from pond harvest to retail sale. Since the product would be sold in “ready-to-eat” form, it was very important that the new facility comply with all USDA and E.U. technical and manufacturing requirements. Prospective equipment suppliers were screened for the hygiene and food safety of their equipment, and also for the yield performance of their cookers and IQF freezers.

GGM also placed high importance on employee safety and working conditions, as well as the environmental impact of various processing options. From a number of capable vendors, we chose several that met our specific needs under the circumstances of this project.

Added-value cooking facility

After initial screening of equipment manufacturers for the seafood industry, GGM chose Carnitech, a Danish manufacturer specializing in seafood equipment. Carnitech offered a turnkey solution based on its experience in seafood processing – including factory layout and design drawings – through to the detailed and specific designs of equipment that could accommodate handling and yield issues specific to our product and production.

The two main parts of the processing line were shrimp cooking and freezing. After running cooking tests comparing water and steam, we selected Carnitech’s patented “isometric steam cooker,” which gave improved yields and superior product quality when compared to water cooking.

Freezing options

The freezing choices considered were cryogenic (nitrogen) and mechanical freezing. The advantage of nitrogen freezing is the lower capital cost, which includes installation cost and a small monthly rental charge. Its downside is the higher running cost. Operational running cost for nitrogen freezers are typically five to seven times higher than for mechanical freezers.

During the early years of nitrogen freezing, the equipment produced significant yield improvements compared to mechanical freezers. However, this is not the case anymore. Today’s modern, redesigned mechanical freezers operate with yields similar to those of nitrogen freezers.

Considering the above, we installed Carnitech’s inline mechanical freezer (with an after-freezer) to ensure product temperatures below minus-8 degrees-F on completing the IQF freezing, glazing, and after-freezing processes.

Other important design aspects

Preparation of cooked, ready-to-eat shrimp requires greater control of processing parameters than freezing or raw product. The new facility included the following design criteria to avoid microbiological or physical contamination of products after cooking:

- For the processing area, a modular building concept was used. All internal walls and ceiling within the processing area were made with insulated stainless steel panels to give optimum hygiene on all surfaces.

- All lights were encapsulated in safety tubes to avoid the risk of broken fragments falling into food products.

- Complete segregation was established between lowrisk (raw) and high-risk (cooked) areas.

- Separate air conditioning units were installed in the high-risk facility to create positive air pressure, which reduces the risk of microbiological contamination from outside air.

- Separate drains were included throughout the facility to separate high- and low-risk areas.

- Different floor levels ensured that no low-risk water could flow to high-risk areas.

- Restricted access was established in high-risk areas to allow only qualified personal to enter.

Refrigeration system

The first decision one must make in selecting a refrigeration system is the type of refrigeration media. Over the past decade, freon-based refrigerants have been widely implicated in depletion of the ozone layer of the atmosphere, and they are being phased out globally through government directives.

Several new refrigerants have been introduced to the market, but these also have been found to cause environmental damage. Consequently, we chose a central refrigeration system that uses ammonia as its refrigeration media. Ammonia has been around for many years, and does not have any known negative effect on the environment.

(Editor’s Note: This article was originally published in the August 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lasse Hansen

Grupo Granjas Marinas

United Kingdom[107,117,46,111,99,46,116,101,110,108,97,98,111,108,103,64,101,115,115,97,108]

Tagged With

Related Posts

Intelligence

A brief look at genetically modified salmon

If approved by FDA, fast-growing genetically modified salmon will provide a safe and nutritious product similar to other farmed Atlantic salmon.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Intelligence

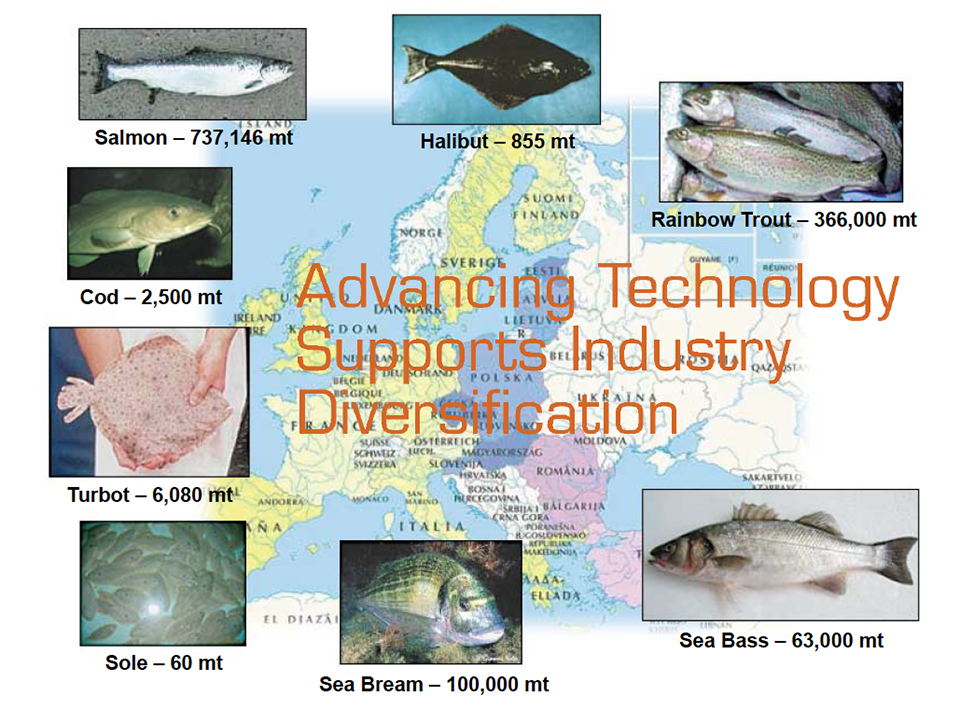

A review of European marine finfish hatcheries

As European aquaculture continues to diversify in the marine fish sector, technology advances and methodology in marine finfish hatcheries are proving vital.

Intelligence

An emerging shellfish farming industry in Namibia

For shellfish farming in Namibia to continue expanding, industry must better comply with approved sanitation standards. The Namibian Shellfish Monitoring and Sanitation Program, currently in development, will help.