Implementing GAA’s responsible aquaculture program

The Global Aquaculture Alliance has initiated the task of implementing its Responsible Aquaculture Program. GAA’s main objectives are to assist shrimp farmers with the application of practices outlined in its “Codes of Practice for Responsible Shrimp Farming” guide, and verify that the practices are being used to improve environmental performance. As part of the plan for implementation, shrimp farmers must conduct a self-evaluation and prepare a compliance plan.

Standards and compliance

The compliance plan will require shrimp farmers to install certain practices, keep records on various activities, and satisfy effluent water quality standards. One of the major environmental concerns about shrimp farming is the possibility that shrimp farm effluents could cause eutrophication and sedimentation in coastal waters. Thus, water quality standards for shrimp farm effluents are an extremely important feature of the GAA program.

Environmentalists and government agencies might accept voluntary environmental management programs relying on best practices, but without effluent standards, for small shrimp farms. However, for large farms, they certainly would not favorably view environmental management programs without effluent water quality standards.

New standards

It is not easy to formulate water quality standards for effluents from a previously unregulated activity such as shrimp farming. Standards must be strict enough to provide environmental protection, or those representing environmental interests will object. On the other hand, standards must not be too strict, or shrimp farmers will not be able to comply with them.

Based on best management practices

A reasonable approach to this problem is to compare water quality concentrations in shrimp farm effluents with water quality limits applied to activities that are currently regulated. This comparison should reveal if some variables in shrimp pond effluents are likely to be outside normally accepted ranges, and suggest the measures necessary to provide a satisfactory effluent. Standards could then be established based on the effluent concentrations that can be expected if shrimp farmers apply the best management practices and treatment methodology economically feasible within the industry.

Literature review

To develop effluent standards for application on large shrimp farms, a literature review was conducted to obtain as much information as possible on concentrations of water quality variables in shrimp farm effluents. The results of the literature review helped establish suggested water quality limits for GAA effluent standards.

Effluent composition

Effluent data were separated according to semi-intensive and intensive shrimp farms using the criterion that intensive farms use mechanical aeration, while semi-intensive ones do not. Depending upon the water quality variable, one to five references dealing with semi-intensive shrimp farm effluents were found, and five to nine references were located concerning intensive shrimp farm effluents.

Variables evaluated

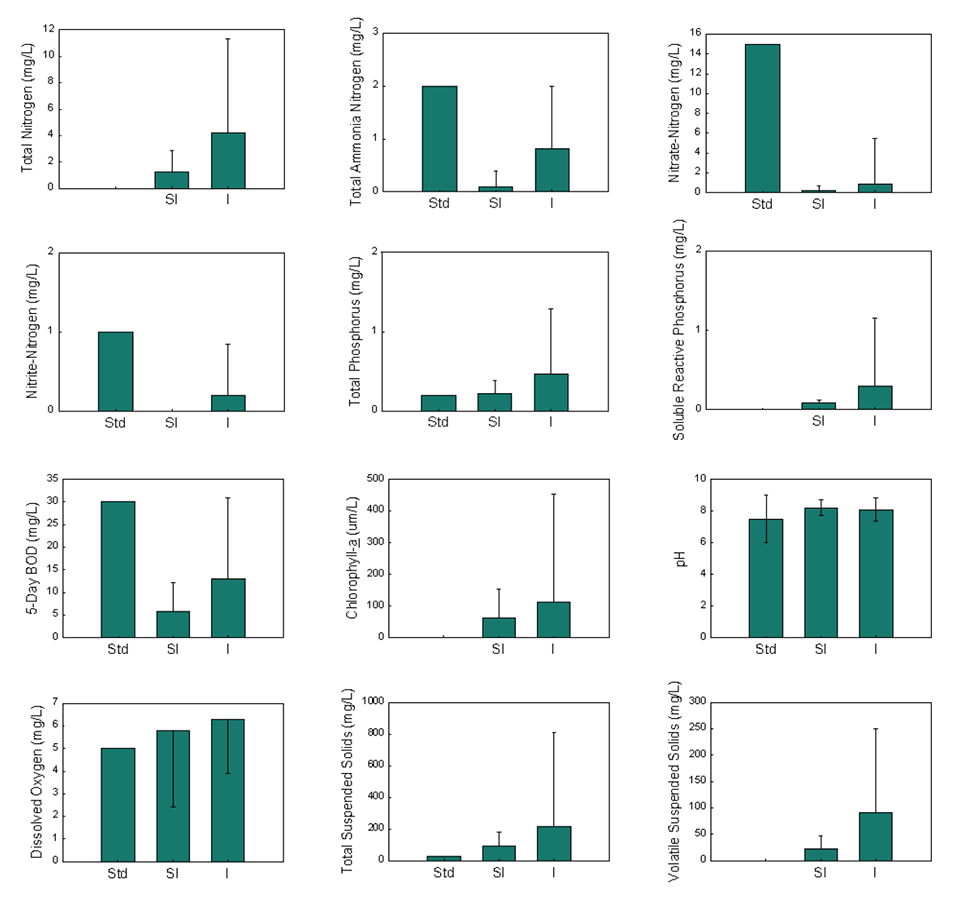

Twelve water quality variables were measured in enough of the studies to permit statistical evaluation, although half of these variables are not commonly included in effluent permits. Findings from these references are presented in Fig. 1 as the averages of all data from semi-intensive farms and averages of all data from intensive farms. Variability in the data is depicted by standard deviations. For each variable, 68.3 percent of shrimp farm effluent samples should contain within ±1 standard deviation of the mean, and 95.4 percent of shrimp farm effluent samples should contain within ±2 standard deviations of the mean.

High variation in concentrations

Variation in concentrations of water quality variables was high as evident from large standard deviations. Means must be used with caution, because the highest concentration of a variable may be twice the mean concentration. Moreover, it is the high concentrations that cause non-compliance with water quality standards. Intensive shrimp farms have more concentrated effluents than semi-intensive farms.

TSS and BOD

For example, total suspended solids (TSS) concentrations averaged 91 milligrams per liter in semi-intensive shrimp farm effluents, and 214 milligrams per liter in effluents from intensive farms. The five-day biochemical oxygen demand was about twice as large in intensive shrimp farm effluents as in those from semiintensive farms. The greater concentrations of suspended solids in intensive shrimp farm effluents result mainly from sediment resuspension by mechanical aeration, but greater phytoplankton abundance from larger nutrient inputs also contributes to suspended solids.

The higher biochemical oxygen demand (BOD) in intensive shrimp farm effluents results primarily from the greater density of phytoplankton. Nevertheless, shrimp farm effluents have very low concentrations of potential pollutants in comparison to untreated municipal or industrial effluents.

Median values

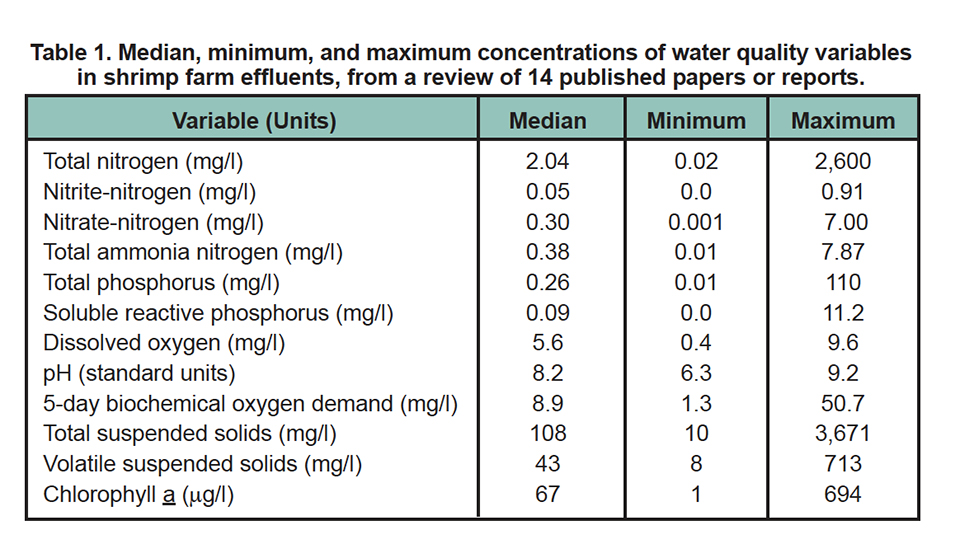

Median values were determined for each water quality variable by using combined data from semi-intensive and intensive shrimp farms (Table 1). Medians tended to be lower than means, suggesting that the distribution of the concentrations were skewed toward lower concentrations.

Median values were quite low for nitrogen, phosphorus, and five-day biochemical oxygen demand. In fact, median values for these factors were within the concentration ranges often found in natural water near shrimp farms. Median values for pH and dissolved oxygen were ideal for aquatic life. However, concentrations of total suspended solids, volatile suspended solids and chlorophyll a were higher than those typically found in natural waters around shrimp farming areas.

Wide-ranging concentrations

Maximum and minimum values (Table 1) reveal a wide range in concentrations of all water quality variables. Minimum concentrations are of concern only for pH and dissolved oxygen. The lowest pH of 6.3 is acceptable because it is not low enough to harm aquatic organisms, but the lowest dissolved oxygen value of 0.4 milligrams per liter would be harmful to aquatic organisms.

Maximum pH exceeded 9.0 in a few samples. High pH is a common afternoon event in ponds with dense phytoplankton blooms and results from removal of carbon dioxide for photosynthesis during daylight hours. Where high pH occurs, it is doubtful shrimp farm effluents would have pH above 9.0 for more than two or three hours per day, and these afternoon excursions of high pH should not be harmful to aquatic life in coastal waters.

Very high concentrations of total nitrogen, total phosphorus, total and volatile suspended solids, and chlorophyll a were measured in a few samples. Nearly all of the exceptionally low or high concentrations of water quality variables were recorded in the final water discharged from ponds during draining for shrimp harvest.

At harvest time, agitated shrimp, wading workers, and rapidly outflowing water resuspend sediment, resulting in high concentrations of nitrogen, phosphorus, suspended solids and biochemical oxygen demand. The suspension and oxidation of sediment, reduced compounds, and organic matter during harvest can result in low dissolved oxygen concentration and a decline in pH.

Effluent water quality standards

Relatively few organizations have prepared water quality standards for shrimp farm effluents. Although three examples of effluents standards are available for the United States, they were not considered suitable for GAA use.

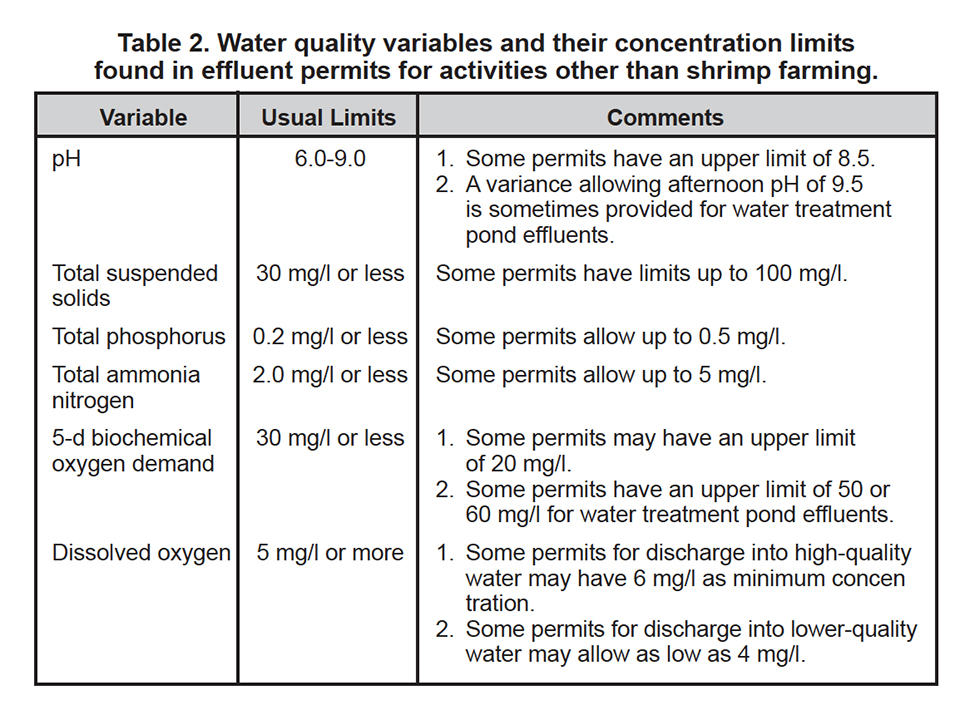

Water quality standards are commonly formulated for inclusion in permits for discharge of municipal, industrial, and other types of effluents. The usual variables and concentration limits found in effluent water quality standards are provided in Table 2.

Variables currently in effluent permits

Only six of the water quality variables that have been carefully measured in shrimp farm effluents (Fig. 1, Table 1) are commonly found in effluent permits. Total nitrogen, soluble reactive phosphorus, volatile suspended solids, and chlorophyll a seldom are included in effluent permits. Nitratenitrogen and nitrite-nitrogen are also rarely used.

Turbidity, which was measured in only one of the effluent studies, is commonly included in effluent permits. Limits on turbidity are typically 25 to 50 nephelometer turbidity units (NTU). Obviously, data on the turbidity of shrimp farm effluents should be collected and evaluated. Incidentally, turbidity has been a major factor (and problem for shrimp farmers) in effluent permits issued to shrimp farms in Texas.

Typical standards

Typical effluent standards for water quality variables are plotted in Fig. 1 for easy comparison with the composition of shrimp farm effluents. This comparison, and maximum concentrations of variables (Table 1), suggest that shrimp farm effluents will often exceed typical limits for total suspended solids and total phosphorus concentrations. Shrimp farm effluents also may occasionally have pH above 9.0 and dissolved oxygen below 5 milligrams per liter.

Adoption of BMPs

Shrimp farms have limited options for effluent treatment. The only economically feasible ways of improving effluent quality appear to be adoption of best management practices (BMPs) and installation of sedimentation basins. Application of BMPs can lower nutrient inputs, reduce sediment resuspension and erosion, and improve dissolved oxygen concentrations. It can also moderate pH and total ammonia nitrogen concentrations in pond waters, with resulting effluents of higher quality.

Nevertheless, on many shrimp farms, application of BMPs alone will not be sufficient to lower total suspended solids and total phosphorus concentrations below limits in typical effluent standards. Total phosphorus is associated mainly with suspended particles, and sedimentation lowers both total phosphorus and total suspended solids concentrations.

Reference practices in GAA codes

References to many better management practices can be found in “Codes of Practice for Responsible Shrimp Farming,” and shrimp farmers can readily adopt these practices. Sedimentation basins are already in use on some shrimp farms, but most farms would have to design and construct them.

Sedimentation basins should have hydraulic retention times of six to eight hours to allow settling of coarse and medium-sized particles, and cause a decrease in total suspended solids and total phosphorus concentrations. Water with a low dissolved oxygen concentration will become re-aerated while standing in the sediment basin. There also should be a moderate reduction in biochemical oxygen demand, and possibly a moderation of pH and some decrease in total ammonia nitrogen concentration through nitrification during retention.

Proposed effluent standards for shrimp farm effluents

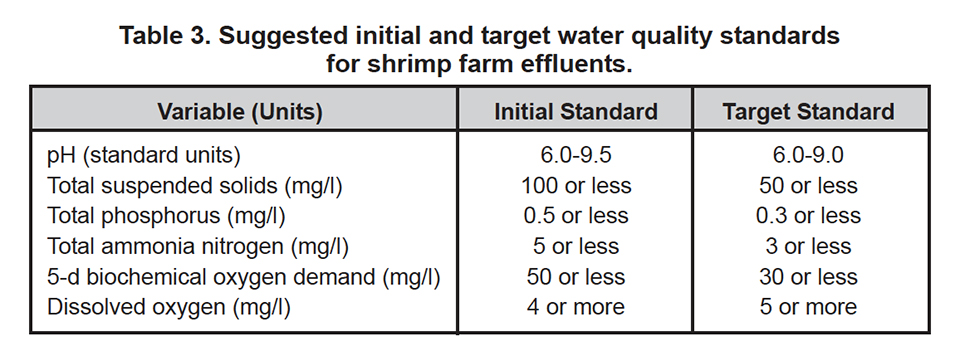

Compliance with newly developed effluent water quality standards cannot be achieved immediately. GAA will begin with rather liberal effluent standards. These will require participants to demonstrate improvements in effluent quality, and ultimately comply with more restrictive target standards.

Semi-intensive farms

Semi-intensive shrimp farms have better-quality effluents than intensive shrimp farms, but the same effluent standards should apply to both types of shrimp culture. It will just be easier for semi-intensive farms to comply with the standards.

Initial standards should be at least strict enough to prevent unusually low pH or dissolved oxygen concentration and extremely high concentrations of other variables (Fig. 1, Table 1). The GAA program uses the most liberal limits observed in other permits (Table 2) as the limits in its initial standards for shrimp farm effluents.

Target standards

The limits in the target standards are about the same as those frequently found in effluent permits (Table 2). Using this approach, suggested standards are listed in Table 3. Although it is common to have a turbidity limit in effluent standards, one was not included in the proposed effluent standards. Usually, if total suspended solids concentrations in aquaculture pond effluents are within acceptable limits, turbidity also will be below the maximum permissible concentration. However, collection of data to verify this generalization would be useful.

More data needed

Of course, it is desirable to collect more data on effluent quality, including turbidity, from a number of different shrimp farms for enhancing the GAA effluent quality database, and to determine how well shrimp farmers comply with the proposed standards. The proposed target standards are generous, so in the future, it may be desirable to lower the concentration limits in the target standards. Nevertheless, compliance with the initial water quality standards and progress towards the stricter target standards will be a major commitment to environmental stewardship by GAA participants.

Small farms

We feel that application of effluent standards to small shrimp farms of a few hectares in size, such as commonly found in Asia, will be extremely difficult. However, application of BMPs could greatly enhance the quality of effluents from small shrimp farms.

Verifying compliance

The monitoring program necessary to verify compliance with standards will be a substantial effort. However, pH and dissolved oxygen can be measured by instruments normally available on shrimp farms, and water analysis kits can be used for total suspended solids, total phosphorus, and total ammonia nitrogen. The biochemical oxygen demand is difficult to measure, so most farms may prefer to send samples to a commercial laboratory for this analysis.

Conclusion

These effluent standards play a significant role in GAA’s Responsible Aquaculture Program because they establish quantitative standards through which program participants measure their adherence to the “Codes of Practice for Responsible Shrimp Farming,” generate an informative self-assessment audit, and ultimately create an ongoing compliance plan reflecting responsible aquaculture practices.

More detailed data tables about each of the studies used in this review are on file at the GAA Home Office. Data includes species of shrimp cultured, stocking density, location, water quality summary, and literature citation.

Our intention is to continually update these tables as additional data becomes available. To receive a copy of these tables or to contribute additional data, please contact the GAA Home Office.

Additional effluent considerations

Although not specifically referenced in the GAA standards, the following best management practices are also encouraged.

Discharge from settling basins can cause erosion within final discharge canals or at outfall points if water velocity is too great. Final discharge should not suspend soil material, and thereby increase the concentration of total suspended solids or create a turbidity plume.

Shrimp farm effluent is brackish water or seawater, and to prevent salinization, it should not be discharged into freshwater or onto agricultural land. As a general rule, the effluent probably should not cause a salinity increase or decrease in the receiving waters of over 10 percent of the seasonal average. It would be difficult to establish salinity limits except on a site-by-site basis.

Shrimp farmers sometimes apply substances to pond water during preparation for the new crop in order to destroy disease organisms and their hosts. Drugs and antibiotics may be applied during crops in response to diseases. When mass mortality of shrimp occurs in ponds, substances may be applied to disinfect pond water as a disease prevention measure before the water is discharged into natural water bodies. Some of these substances can be harmful to native aquatic organisms. After pond treatments, water should be held in ponds with no discharge until the potentially harmful substances have degraded.

Water quality permits may specifically state that foam, scums, or turbidity plumes should not be visible at the discharge point. Shrimp farm effluent sometimes has foam on its surface. This foam probably can be contained in settling basins if a floating skimmer is mounted across the discharged end of the basin. Sedimentation should prevent turbidity plumes resulting from suspended soil particles, but discoloration of effluent by plankton can also result in a turbidity plume. The only method for preventing this plume would be subsurface discharge.

Water quality permits may specifically state that foam, scums, or turbidity plumes should not be visible at the discharge point. Shrimp farm effluent sometimes has foam on its surface. This foam probably can be contained in settling basins if a floating skimmer is mounted across the discharged end of the basin. Sedimentation should prevent turbidity plumes resulting from suspended soil particles, but discoloration of effluent by plankton can also result in a turbidity plume. The only method for preventing this plume would be subsurface discharge.

The management practices suggested in “Codes of Practice for Responsible Shrimp Farming” can prevent suspension of soil particles during final discharge, salinization, and discharge of toxic chemicals.

(Editor’s Note: This article was originally published in the October 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Claude E. Boyd, Ph.D.

Department of Fisheries and Allied Aquacultures

Auburn University, AL, USA[117,100,101,46,110,114,117,98,117,97,64,49,101,99,100,121,111,98]

-

Dominique Gautier, M.S.

Department of Fisheries and Allied Aquacultures

Auburn University, AL, USA

Related Posts

Responsibility

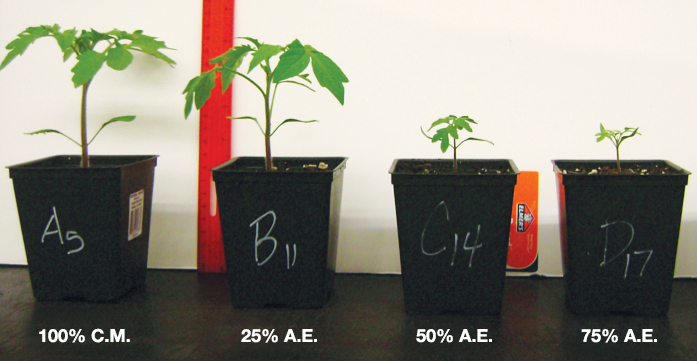

Aquaculture effluent partially replaces growing mix for plant production

Aquaculture effluent can be an effective fertilizer in land-based plant production. Research with tilapia utilized dewatered aquaculture effluent (A.E.) as a partial substrate replacement for tomato plant seedlings. Seedling growth decreased when effluent replaced a commercial growing mix at 25 percent or more.

Health & Welfare

Bacterial pathogens in biofilms pose health risks in recirculating systems

Recirculating aquaculture presents an increased potential for pathogenic bacteria to become established in the system through the formation of biofilms.

Responsibility

Cage design, placement affect water quality

Farm cages should be sited where water quality is good and water velocity is adequate. The size, shape and position of cages should be selected to favor rapid flushing.

Intelligence

End-of-pipe water treatment at salmonid hatcheries in Norway

Most of the approximately 250 Norwegian salmonid hatcheries are located on the coast and close to a freshwater source.