Results of trials at commercial shrimp farms in Ecuador show improved production indicators

Currently, there is a trend to identify production areas that can be improved and to make adjustments that can help make aquaculture farms increasingly efficient and profitable by adopting new technologies in these areas. In shrimp aquaculture, these areas are fairly well identified; one involves manufactured aquafeed that makes up a considerable cost of production, and another one involves feeding strategies.

This article – adapted and summarized from the original publication [Molina Poveda, C. and M. Espinoza Ortega. 2020. La extrusión del alimento combinada con tecnología de alimentación acústica, maximiza la producción en el cultivo del camarón (Feed extrusion combined with acoustic feed technology maximizes production in shrimp farming). Revista Aquacultura, Cámara Nacional de Acuacultura (Ecuador), No. 140 (October 2020), p. 48–52] – reports on trials evaluating pelleted and extruded diets, and manual and automated feeding at commercial shrimp farms in Ecuador, and the potential to significantly improve growth and reduce the feed conversion ratio (FCR) in Pacific white shrimp (Litopenaeus vannamei) juveniles.

Advantages of extruded vs. pelleted aquafeeds

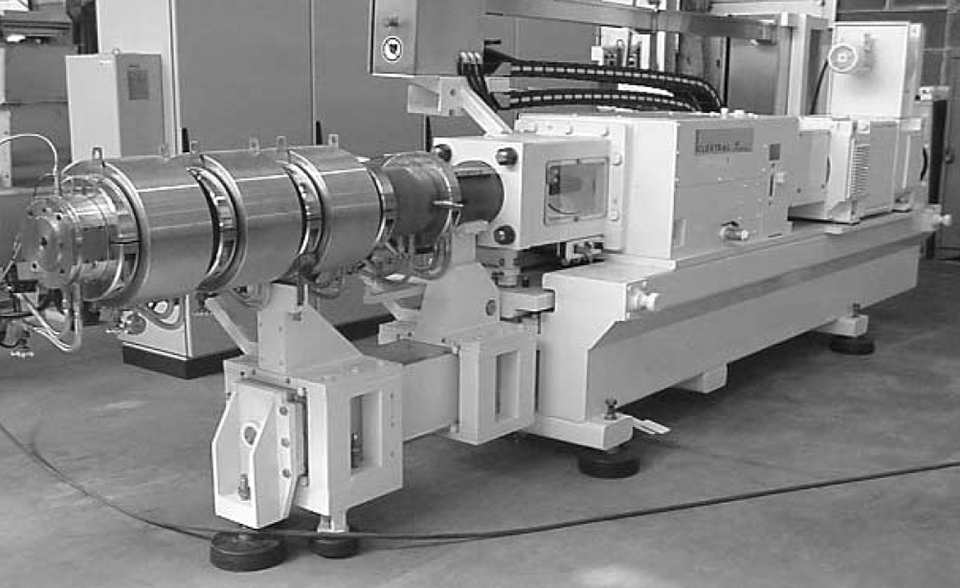

There are important differences between feed manufacturing processes. Extrusion as a processing technology was adapted from different applications to the feeding of aquacultured species and represents one of the most versatile and energy efficient developments when it comes to the cooking of feed ingredients.

One of the greatest challenges to adapt extrusion for shrimp feeds and farming was to accomplish the sinking of the extruded pellets, which was achieved with degassing systems designed in such a way that they allow the extraction of water in the form of steam, which in turn allows the extruded pellets to be 100 percent sinkable.

A wide variety of configurations or technology options for the production of extruded shrimp feeds is available. For example, with the use of twin-screw extruders with specific mechanical energy control, the shear rate is regulated by managing the speed of the screws. This way, it is also possible to compensate for wear so that the mechanical energy is constant. Finally, with pellet density control it has been possible to improve feed stability in the water, as well as other characteristics and advantages when compared to traditional pelletizing.

Extrusion has a leading role in the context of modern aquafeed production. Unlike pelleting, the extrusion process includes cooking and mixing ingredients at high temperature and pressure for a short time (≈5 seconds). Extrusion can be used for the development of feeds with specific applications, as it allows better management of raw materials, and the use ingredients previously regarded as inadequate due to nutrient composition. On the other hand, extrusion as a multifunctional manufacturing process allows several applications for the production of aquaculture feeds for larval, nursery and grow-out.

Extrusion manufacturing conditions have a direct impact on the physicochemical properties of the feeds, which can affect the durability and stability of the pellets. The conditions during processing can also affect the nutritional quality of the ingredients and therefore influence digestibility. In addition, the extrusion process denatures undesirable enzymes and deactivates some anti-nutritional factors, which enhances the bioavailability of the ingredients.

In the early days of using automatic feeders, the combination of these with pelleted diets affected production parameters. However, in the of shrimp feeds, we foresee a continuous and progressive migration to extruded feeds, which can better withstand physical stress without breaking up, and ultimately allow the entire nutritional package to be completely delivered directly to the shrimp being fed.

This was the case in the Chilean salmon industry in the 1980s, when it took a few years for the benefits of using extruded diets in combination with marine cage feeders to become fully evident and for producers to grasp the benefits of this technology. This evolution in salmon farming towards the use of extruded feeds most likely accelerated because feeds are transported to the feeders in sea cages using pneumatic hoses. These work with air currents that carry the feed from a mother hopper to the feeders and make the generation of feed fines (dust) and feed breakage and disintegration in pelleted feeds much more evident.

Therefore, in the next few years there could be a gradual replacement of pelleted feeds for shrimp. This process would be faster in some regions than in others since feed extrusion plants require greater investment and specialization to operate. However, the benefits of extruded aquafeeds compensate for the price and complexity of manufacturing operations, making this technology increasingly acceptable to producers due to its adaptability to automation in the dispensing of the feed in production ponds. Efforts should focus on how to improve extrusion methods for shrimp feeds to further improve their suitability for use with automatic feeders.

Several authors have reported on the advantages in the use of extruded feed in crustaceans. For example, Misra et al. (2002) working with giant freshwater prawn (Macrobranchium rosembergii) post-larvae (14.5 to 14.9 mg) fed with pelleted and extruded feeds for 60 days, reported better specific growth rate, hydrostability and protein efficiency ratio for the extruded feed. And the loss of nutrients was minimal in the extruded feed, which was verified by a reduction in the feed conversion factor.

Chamberlain (2004) evaluated two pelleted and extruded feeds in two different sizes of L. vannamei juveniles stocked at 50 shrimp per square meter for 12 weeks; results showed greater survival and weight gain, as well as greater feed efficiency for animals receiving the extruded feed. And Tacon et al. (2003) demonstrated that extruded feeds produced better growth than pelletized feeds when tested in 0.95 grams shrimp in an indoor tank system with clear running water. More recently, published results by Molina and Espinoza (2019, 2020) showed better performance of extruded feeds due to improvements in protein, carbohydrate and amino acid digestibility. Additionally, better physical characteristics of extruded feeds maintain their integrity when using automatic feeders.

The conditions during processing influence the nutritional quality of the ingredients and, consequently, influence digestibility, as shown by Welker et al., (2018) for rainbow trout. In addition, the extrusion process denatures undesirable enzymes and deactivates some anti-nutritional factors that improve the bioavailability of ingredients. This same effect was reported by Molina and Espinoza, (2020) for L. vannamei juveniles, where trial results showed that the digestibility coefficients of various amino acids – arginine, isoleucine, lysine, methionine, threonine, glycine and proline – were significantly higher in extruded feed than in pelleted feed.

Extruded feeds in automatic feeding

Better flow in hoppers

Extruded feeds are well-suited to the operation of automatic feeding equipment. The minimum amount of fines generated favors the continuity in the work of the dispensing motors, located under the hoppers where the feed is deposited. Other types of non-extruded feeds generate fines, which affects the components of the feeding system, causing jams and mechanical failures. And the firmness of extruded feeds, as well as its properties for easy flow, are also very important to maintain the continuous operation in an automatic feeder.

Also, the easier discharge into hoppers of the automatic feeders is due to the fact that the length of the extruder cut is constant and precise, which results in greater homogeneity in the feed pellet length and with it a greater number of feed pieces per kilogram, compared with pelleted feeds. This in turn allows a better, more compact and efficient arrangement of the extruded pellets within the hopper, with less space between pieces.

Regarding the interaction between the feeder hopper and extruded feeds, it should be noted that the designs and selection of materials for hoppers have improved considerably in recent years. Hopper materials must allow uninterrupted flow, and the coefficient of friction between the feed and the hopper material must be as low as possible. Also, the free flow of feed in the hopper is highly dependent on the angle of inclination in the discharge cone, but the coefficient of friction between the feed and the material also influences.

Because extruded feed is smoother, it generates less friction (lower coefficient of friction), which leads to a better discharge compared to pelleted feed (Fig. 1). Pelleted feed tends to get stuck in certain parts of the hopper, forming a “funnel” pattern (Fig. 1A), while extruded feed flows freely in mass flow towards the lower opening (Fig. 1B).

Greater resistance to mechanical stress

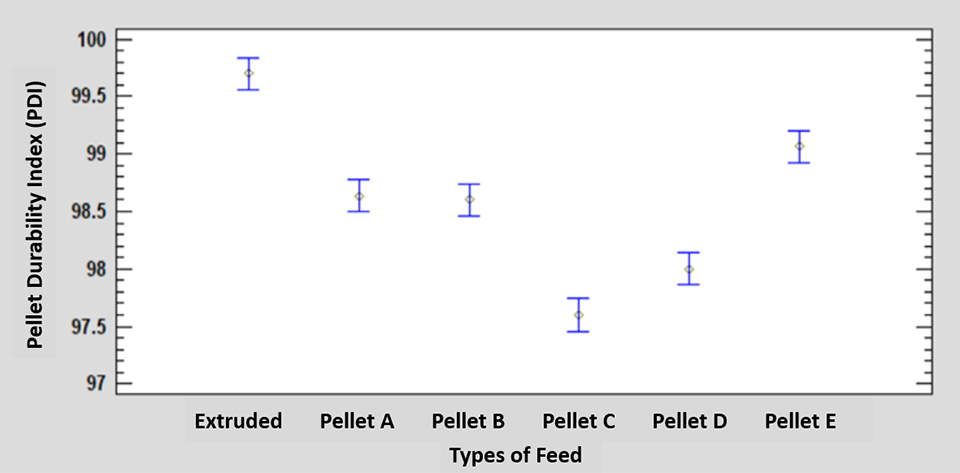

Another aspect of vital importance is the resistance of extruded feeds to their passage through the dosing motors. Extruded feed has higher strength than pelleted feed. An indication of the resistance by manufactured aquafeeds to mechanical stress is the pellet durability index (PDI). To evaluate the differences in resistance of an extruded feed and various pelleted feeds, we carried out a resistance trial using a Holmen NHP 100 (New Holmen Portable Pellet Tester, Holmen Feed, Norfolk, UK). In this device, a stream of air in a turbulent regime agitates a feed sample inside a perforated chamber, constantly eliminating the feed fragments that are separated during the test. The hopper had 2.5mm diameter perforations and the timer was set to 120 seconds. Results showed greater resistance in the extruded feed over any of the pelleted feeds tested (Figure 2). Having a high hardness index allows manufactured feeds to better withstand handling, storage and transportation, as well as dosing through automatic feeders.

The trend of pneumatic transport of feeds to feeding hoppers in shrimp farms is gaining momentum, so the determination of the PDI is a way of predicting the resistance that each type of feed will have under these conditions of mechanical stress. During this type of (pneumatic) transport, pelleted feeds – unlike extruded feeds – break down and generate dust and particles that are no longer consumed by the target animals.

Better sound characteristics

Due to its physical characteristics, extruded feeds would seem to be ideal to use in combination with acoustic automatic feeders, because their greater hardness could be an advantage for sound detection. Peixoto et al. (2020) reported that the texture of the diets was closely related to the acoustic intensity when the shrimp were feeding, so that a greater hardness of the extruded diet may be an advantage for improved sound detection by shrimp.

Field trials

We selected data for 639 shrimp earthen ponds, averaging 8 to 12 ha in area, and located in the Province of Guayas, Ecuador; the data for these ponds is for the 2018 to 2020 production period. Shrimp on these ponds were fed 35 percent protein, commercial pelleted and extruded diets. The production period was selected to evaluate the effect of the type of feed (pelleted and extruded) and the feeding strategy used (manual, automatic-timer and automatic-acoustic) on shrimp growth, survival, yield and feed conversion. The manual broadcast feeding one or two times a day corresponds to the established protocol and management applied by each shrimp farm with ponds fed nutritionally complete, 2.0 mm diameter pelletized feeds and 1.9 mm diameter extruded feeds.

Regarding the data from automatic feeding with time adjustments, solar feeders with timers were used, programmed to distribute feed every hour in a dispersion radius of 12 to 15 meters. As was for manual feeding, these diets were 35 percent protein with the same pellet dimensions. Two brands of automatic feeders were used for pelleted feeds, and a third brand with similar characteristics was used for extruded feeds.

A third group of production cycles, based on the use of two brands of automatic [acoustic) feeders with hydrophones, were remotely connected to computers that ran a program that processed the sound generated by the shrimp’s jaws when feeding on the pellets, and calculated the amount of further feed to distribute.

Results show that ponds using manual feeding of extruded feeds generated higher yields (49 vs. 40 lbs. per ha per day) than ponds receiving pelleted feeds, even though the production cycle lasted 12 days longer (Table 1). The same trend occurred for the automatic feeders with timers, with higher yields in the ponds that used extruded feeds. However, although their FCR was somewhat higher, their harvest weight was 3 grams more than the final weight reached with the pelleted feed. And a yield 22 percent higher resulted when the extruded feeds were supplied with automated acoustic feeders.

Molina, Extruded Feeds, Table 1

| Parameter | Manual Pellet | Manual Extruded | AA Timer Pellet | AA Timer Extruded | AA Acoustic Pellet | AA Acoustic Extruded |

|---|---|---|---|---|---|---|

| Pond number | 179 | 237 | 39 | 89 | 42 | 53 |

| Pond average area (ha) | 8.7 | 8.5 | 5.4 | 7.9 | 12 | 11.8 |

| Stocking density (shrimp/ha) | 159,223 | 187,407 | 166,411 | 170,294 | 201,818 | 215,645 |

| Production days | 103 | 115 | 107 | 113 | 128 | 110 |

| Average cumulative feed (kg/ha/day) | 30.96 | 39.93 | 33.12 | 37.85 | 30.15 | 44.11 |

| Harvest weight (g) | 22 | 23 | 21 | 24 | 26 | 27 |

| Harvested biomass (lbs.) | 37,225 | 44,152 | 25,031 | 41,101 | 65,898 | 80,116 |

| Production (lbs./ha) | 4,075 | 5,195 | 4,411 | 4,989 | 5,711 | 6,327 |

| Yield (lbs./ha/day) | 40 | 49 | 43 | 45 | 46 | 59 |

| FCR | 1.72 | 1.93 | 1.65 | 1.89 | 1.96 | 1.67 |

| Survival (%) | 53 | 57 | 59 | 54 | 52 | 52 |

| Growth rate (grams/week) | 1.49 | 1.44 | 1.39 | 1.53 | 1.44 | 1.72 |

| Shrimp cost (US$/lb.) | 1.61 | 1.61 | 1.50 | 1.54 | 1.58 | 1.3 |

For stocking densities, we observed that, in general, the acoustic feeder strategy supports increasing the number of animals per area and still achieve a larger final weight. The number of days per cycle were 10 percent less when the combination of extruded feed and acoustic feeders was used, vs. pelleted feeds and acoustic feeders.

The average cumulative feed corresponding to the extruded feed – acoustic feeder combination is comparatively higher (44.11 kg per hectare per day) compared to all the other strategies and their combinations. This resulted in a higher weekly growth rate (1.72 grams per week), as well as more pounds harvested on average (6,327 lbs. per ha) for this combination. A decrease in FCR is evident when compared with the pelleted feed – acoustic feeder combination (1.67 vs. 1.96). Timer feeders and extruded diets also showed better results than timer feeders and pelleted diets in terms of pounds harvested and yield.

Acoustic feeding strategies had 52 percent average survival, which would be related to the highest final weight achieved (27 grams), compared to other strategies that reached 23 grams of average final weight with average survival of 55 percent.

In general, the acoustic feeding strategy makes production differences more evident when comparing pelleted vs. extruded diets. The cycles that received extruded feeds using acoustic auto-feeders achieved the highest growth and feeding efficiencies, with a reduction in the number of production days (around 18 days).

Perspectives

Precision aquaculture requires a combination of physical, nutritional and managerial factors, all part of a disruptive approach increasingly needed. The characteristics of extruded diets, physical, chemical and biological, allow a better, more efficient use of feed nutrients due to their greater cooking, which, added to the automatic distribution improves shrimp productive indicators, providing improved growth and feed conversion.

Better nutritional quality of extruded feeds (with better digestibility for protein, carbohydrates and essential amino acids) added to the correctly timed, on-demand distribution of feeds improves shrimp growth and feed efficiency.

With more shrimp farms adopting extruded feeds – which supports improved shrimp performance – we expect shrimp production to increase without additional production (ponds) area, which should also reflect on the sustainability of the industry.

References available from the corresponding author.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

César Molina Poveda, Ph.D.

Corresponding author

Investigación y Desarrollo. Skretting Ecuador[109,111,99,46,103,110,105,116,116,101,114,107,115,64,97,110,105,108,111,109,46,114,97,115,101,99]

-

Manuel Espinoza Ortega, M.Sc.

Investigación y Desarrollo. Skretting Ecuador

Tagged With

Related Posts

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

Demand feeding through automatic dispensing systems

Studies showed that the demand feeding system for farmed shrimp – based on multi-rations and combined with sound detection – can be used to distribute the correct dosage of aquafeed with high nutritional density.

Aquafeeds

Extruded shrimp feeds reemerge

The process for making extruded shrimp feeds has flexibility to produce diets with a wide range of fat levels, densities, shapes and sizes.

Aquafeeds

Extrusion processing of aquatic feeds, Part 1

Depending on the extrusion processing conditions and ingredients used, different products such as floating or sinking feed can be produced.