Israel-based Agam’s automatic, ‘in-habitat’ sorting and counting system reaches second prototype phase

As VP of AgTech at Trendlines, an investment firm in Israel, Maya Schushan Orgad has assessed current aquaculture technology and concluded that it’s “medieval” and lagging behind other food sectors that have embraced automation. That’s why she seized the opportunity to invest in Agam, an Israeli company developing an automatic, in-habitat fish sorting and counting system.

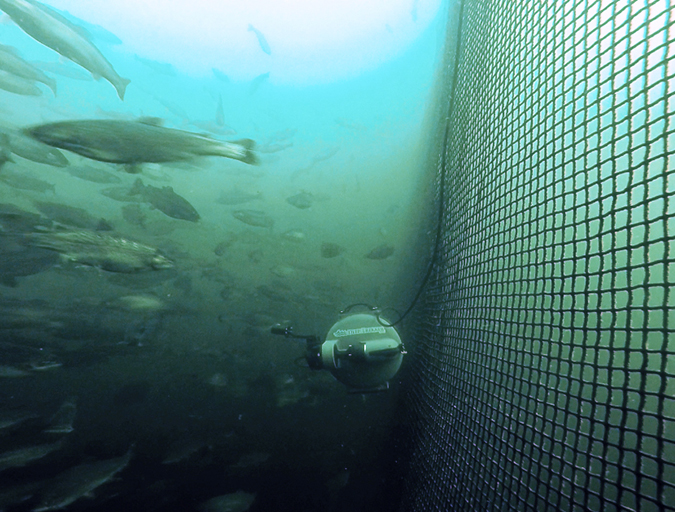

Launched in 2018, Agam has been working on an in-water, sensor-based and electro-mechanical system that consists of a sorting cage and storing net with the goal of automating the labor-intensive tasks of sorting and counting on fish farms while improving accuracy and harvest yield.

With Trendlines’ support as well as funding by the Israeli Innovation Authority, Agam has reached the proof-of-concept stage after testing a prototype in three inland fish farms, sorting and counting three tons a day of fish like tilapia and carp, two of the world’s most important commercially produced species.

Fish farmers at both large and small operations know the challenge of having to manually catch fish to assess their size for optimal harvest times.

“It’s a lot of labor and very intense work,” said Eli Liraz, CEO of Agam Aquaculture. “It’s also not accurate. They must throw the net again and again as they evaluate if they have enough fish of the desired size.”

Such a manual process also puts stress on the fish, he said, which can significantly impact their health and affect the yield.

With the Agam system, users first set the type of fish as well as a desired size to sort. This alters the compartment openings of an underwater cage, only permitting fish of a certain size to enter. After fish are enticed into the sorting cage via feed or luring materials – which depend on type of fish and other variables, such as time of day – sensors count the fish and estimate the fish’s weight while software calculates biomass. Once the desired quantity of an ideal size is collected, the fish are moved to an adjacent storing net.

There’s a lot of room for new technology like this to create substantial value.

An obvious application is to use the system to sort and count big fish, which land higher prizes on the market. Yet the system is also useful for sorting and collecting smaller fish, Liraz explained, either to take them out of the breeding pool or to move them to another pond in order to feed them without competition from bigger fish. “This way, the whole farm can reach the optimal size for harvest,” he added.

Because this process occurs in-habitat, it’s better tolerated by the fish, Liraz said, noting that instances of mortality and damage can affect up to 15 percent of a harvest. “With our software, we can also check when fish are eating or if they need to eat,” he said. “We can even follow the known curve of growing and if we see fish are not growing, we can alert farms as issues arise in real time.”

Partial harvesting also gives fish more space and oxygen per square cubic meter as farmers can remove the larger fish ready for harvesting before they keep eating feed and adding pollution to the water.

“This leads to a better feed conversion ratio as well as reduced water consumption because farmers don’t have to add more and more water to keep it clear,” Liraz said. “You can then also use the pond water as a source of irrigation.”

To date, Agam has been part of Trendlines’ incubator program, in which the investment company provides seed money and support towards a disruptive technology during its early stages when it may be viewed as too risky by other investors.

“One of our investment focuses is aquaculture because it is an emerging, growing market, but it’s lagging back from other agriculture areas in terms of technology, disruption and adaptation,” said Orgad of Trendlines. “There’s a lot of room for new technology like this to create substantial value.” For example, a farm with 10 hectares of tilapia and a yield of 220 tons can expect a return on investment from the Agam system within 1 to 2 years, according to Liraz.

To date, Agam’s product testing has focused on inland fish farms but Liraz says the system is suitable for ocean farming as well because the sensors can function in any water type and for any fish species. After reaching proof of concept, Agam developed a second prototype with added improvements that will launch in test sites soon.

“We’ve upgraded the control system and found a way to expedite how fast the fish move from the sorting cage to the storing net by narrowing the size of the cage and changing the water volume,” he explained.

Meanwhile, for investors like Trendlines, the clear practical advantage of such a system is an enticing opportunity. “The system is either sorting and counting or it’s not,” said Orgad. “The advantages are very easy to see and to quantify.”

Agam is currently seeking industry partners to complete product development and launching its round-A funding effort with the hopes of going to market in 2022.

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Amanda McCorquodale

New York-based freelance writer Amanda McCorquodale covers emerging trends in the food industry.

Tagged With

Related Posts

Innovation & Investment

One fish, two fish: Counting technology nets funding for Canadian engineering firm

XperCount, aka the “magic bucket,” uses optics and photonics to deliver 95 percent accurate count of microorganisms, such as fish or shrimp larvae, in just seconds.

Innovation & Investment

Little fish in a big pond: Minnowtech aims to give fresh vision to shrimp inventory

Because shrimp farmers lack accurate in-pond inventory, startup Minnowtech is on the verge of offering a data-driven solution. It’s got something to do with jellyfish.

Innovation & Investment

Fish behavior-tracking tech aims to curb aquafeed wastage

Overfeeding is a waste stream for aquaculture. Underwater cameras in pens help, but a company mixing hydroacoustics and machine learning has another idea.

Innovation & Investment

Rise of the machines: Aquaculture’s robotic revolution

Technological advances are revolutionizing aquaculture. From airborne inspection tools to underwater drones, innovative robotics and automation technology are unveiling a brave new world of futuristic farming.