FEDEACUA leads sustainable development

Colombia has taken on challenges to enhance its competitiveness and productivity in the aquaculture sector, which have been led by FEDEACUA — Colombian Federation of Aquaculture (www.fedeacua.org), a national guild formed in 1998 that represents inland fish farming with the production of tilapia, trout, and cachama and other native species. FEDEACUA in his role as a national guild leads the sustainable growth of the activity and develops a prospective of technical work through four technical axes of functional work: AQUASOST, Science and Technology Unit; AQUAGAP TECNIPAB, Technical Assistance Unit; EDUAQUA, Aquaculture School for the Productive Sector; and INFOAQUA, Observatory for the Competitiveness of Fisheries and Aquaculture.

Colombian aquaculture production

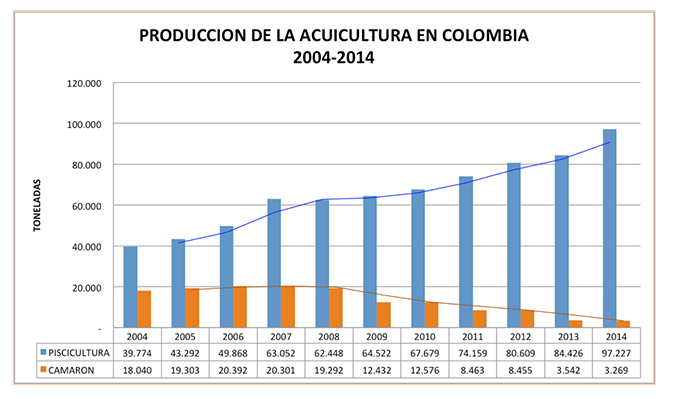

The dynamics of production of inland fish farming (tilapia, trout, cachama and native species) in Colombia had an annual growth of 15 percent in 2014, up from 84,426 metric tons (MT) produced in 2013 to 97,227 MT in 2014 (Ministry of Agriculture and Rural Development 2015). Exports of inland fish farming products (tilapia and trout) grew 34 percent in the same period, from exporting $37,133,596 in 2013 to $49,889,604 in 2014 (PTP – FEDEACUA Analysis). These figures indicate that fish farming is an important sector of Colombia’s agro industry and is growing at two-digits. And these data lead to very interesting figures in terms of job creation, social investment, development of small farmers and food security, among others. The following graphs show the evolution of aquaculture in Colombia in terms of production and exports:

Production of the Colombian aquaculture industry during 2004-2014, and Colombian exports of aquaculture products in USD million for the same period. Source: MADR 2015 – PTP – FEDEACUA Analysis.

Production of the Colombian aquaculture industry during 2004-2014, and Colombian exports of aquaculture products in USD million for the same period. Source: MADR 2015 – PTP – FEDEACUA Analysis.

This significant growth in production and export markets has been due to a large degree to the efforts of the industry and the producers’ guild. Since 2010, with FEDEACUA under an international cooperation agreement with Germany (Project GIZ, Deutsche Gesellschaft für Internationale Zusammenarbeit; GmbH, INWENT), developed a methodology for implementation of quality standards for aquaculture with emphasis on small producers, which currently is – in the organizational structure of FEDEACUA, a technical assistance unit called “AquaGAP – TECNIBAP,” which encourages producers in Colombia to obtain international quality seals required by the markets.

Methodology

The methodology currently developed and implemented in Colombia consists of a qualification method in a technical advisory mode for each production unit, through which the following are carried out: a diagnosis, an implementation plan, an internal audit and monitoring of the evolution of compliance with an international standard required by the market, like Best Aquaculture Practices (Global Aquaculture Alliance; BAP). The usual qualification method by a body-accredited auditor has the options of Complies/Not Complies and leaves challenges that must still be met in the non-conformities. The methodology used by FEDEACUA emphasizes the main verification by the body-accredited auditor, consisting of the review of records and certificates, conducting visual inspection, meeting in an interview with those in the production unit for process compliance, verifying the traceability scheme, and determining if they conduct self-evaluation processes. The qualification or rating method is as follows:

| Qualification | Interpretation |

| 1 | Not documented, Not implemented |

| 2 | Not documented, Implemented |

| 3 | Documented, Not Implemented |

| 4 | Documented, Implemented |

| 5 | Documented + Implemented+ Internal Audit |

Source: FEDEACUA – Program for Integral Quality Assurance

Transferring technical knowledge to small, medium and large producers from the technical point required by each standard is not easy, more so when it must be intertwined with existing national regulations. This is why the methodology developed by FEDEACUA is a permanent aid for producers because it specifies the difference between having registration and obtaining certificates. The latter involves visual inspection, preparing the workers of the production unit so that they can demonstrate knowledge through constant training in Food Safety, Animal Welfare, Social Development, Environmental Sustainability and Traceability, and socializing the interpretation of the implementation of existing national regulations, among others.

The technical team in FEDEACUA has official training on the following main quality standards for aquaculture: GlobalGAP; BAP-GAA, Best Aquaculture Practices by the Global Aquaculture Alliance; Aquaculture Stewardship Council (ASC); SQF, Safety Quality Food and the comprehensive package of HACCP International.

Quality standards are voluntary ones adopted and implemented by agricultural producers worldwide, responding to a commercial requirement to remain in that market. In the case of Colombian aquaculture, the production of tilapia and trout constantly faces this requirement in its trade negotiations with the United States, Canada, the European Union and Peru. This is why FEDEACUA undertook the development of this comprehensive program to improve the competitiveness of its inland fish farming sector, through the implementation of a technology package.

Program achievements

During 2014, 13 international labels were obtained for primary production and processing, covering 12 percent of the national production under the standards of BAP, ASC and the SMETA audit, which have a positive impact on exports with a growth of 26 percent during the first two months of 2015. Regarding processing plants, these increased from 9 to11 facilities with HACCP certification that improves their competitiveness in the domestic and export markets. And since Good Aquaculture Practices (Buenas Prácticas Acuícolas, BPA) is a recent topic for the aquaculture sector, FEDEACUA implemented a national training scheme “EDUAQUA,” the aquaculture school for academic training, which in 2014 trained 668 people (512 in the productive sector and 156 at institutions involved in the development of the activity). During 2015, they continued strengthening the program and aimed to obtain 40 seals of international certification for tilapia and trout producers, which not only are a tool for the export market but also will help achieve a better position for the commercial scheme in the local market.

Perspectives

Finally, it is noteworthy that the implementation processes take on average 18 months from the diagnostic to the accredited audit visit, during which the integrity of the production chain must be reviewed (seed production, grow-out system, chain of custody, processing plant and suppliers of concentrated feeds). For this, FEDEACUA has designed 24 technical programs to implement that cover 250 requirements of the international standards with their respective regulatory analysis of Colombian legislation and the design of traceability formats, among others, to ensure that Colombian producers have access to quality certification and improve their participation in domestic and export markets.

Author

-

Sara Patricia Bonilla

Executive Director

FEDEACUA – Colombia Federation of Aquaculture Producers

Cra. 7 #32-29 Oficina 1303

Bogotá D.C., Colombia[103,114,111,46,97,117,99,97,101,100,101,102,64,112,115,97,108,108,105,110,111,98]

Tagged With

Related Posts

Health & Welfare

Parasite treatment reduces F. columnare infection in tilapia

The authors conducted a study to evaluate whether treatment of Trichodina-parasitized tilapia with formalin would improve fish survival and reduce F. columnare infection. Tilapia not treated with formalin showed significantly higher mortality than treated fish.

Intelligence

Global finfish production review: Gradual growth

Recent surveys indicate that global finfish production has doubled over the last decade, but most of this growth happened in the first half of this period. Production is still growing but at slower pace than in recent years, and annual growth rates must increase to at least 7.2 percent to maintain the double-in-a-decade objective.

Intelligence

Commercial implementation of in-pond raceway system

An in-pond raceway system in Alabama was utilized to supply various niche markets, including Asian grocery store chains that desired fresh live fish, recreational pond stocking businesses, private pond owners and fee fishing operations. In many cases, a higher price was achieved.

Responsibility

Rice-fish integration for high saline, coastal areas of Bangladesh

The Southwestern coastal zone of Bangladesh is agro-based and one of the world’s most populous, poverty-stricken and food-insecure regions. There is an opportunity to diversify and increase productivity by integrating rice with aquaculture during the monsoon season through adoption of water management practices.