Natural biofilters improve water quality

In aquaculture production systems, no more than about 30 percent of the nitrogen in formulated aquafeed is retained as growth by the cultured species while the excess is mainly released as dissolved, toxic ammonia. Most aquaculture species have a low tolerance to ammonia-toxicity, and a high rate of water exchange is necessary to maintain adequate culture conditions. To reduce the use of fresh seawater by implementing recirculation, many land-based production systems have adapted the use of bacterial biofilters that convert ammonia into less toxic forms, but the discharge may still have an environmental impact. The use of integrated mariculture systems incorporating seaweed (sea lettuce, Ulva lactuca) biofilters is a relatively new approach that addresses this issue and promotes more sustainable production.

Seaweed biofilters

Fish or shrimp excretions serve as fertilizer and are converted into algal biomass, stripping significant amounts of nutrients from the effluent. Previous small-scale experiments by Neori et al. (1996) on modular integrated systems at the integrated system department of the National Center for Mariculture in Eilat (southern Israel) have shown that it is possible to reuse seawater once it has been purified through a seaweed biofilter. When grown under a high nutrient supply, the algae contain high levels of protein and are a suitable food for macroalgivores like abalone or sea urchin. Seaweed is also an ingredient in the increasingly popular East Asian cuisine, and the health food and cosmetics industries.

Integrated system

With financial support from the Israeli Ministry for Infrastructure and a European Union grant, we tested an intensive, recirculating, integrated system of gilthead sea bream, Sparus aurata, and sea lettuce. In addition to practical system improvements, its goal was upscaling to a semi-commercial level and closely assessing the abiotic interactions between the system modules.

Aspects monitored were seaweed production and 24-hour fluctuations of temperature, dissolved oxygen, water pH, and dissolved nutrients. The experiment was carried out during autumn 2000 and winter 2001, generally a critical time when lower solar irradiance and temperature can lead to reduced seaweed performance. The effects of a bio-filter greenhouse on the system’s heat budget were also evaluated.

System design

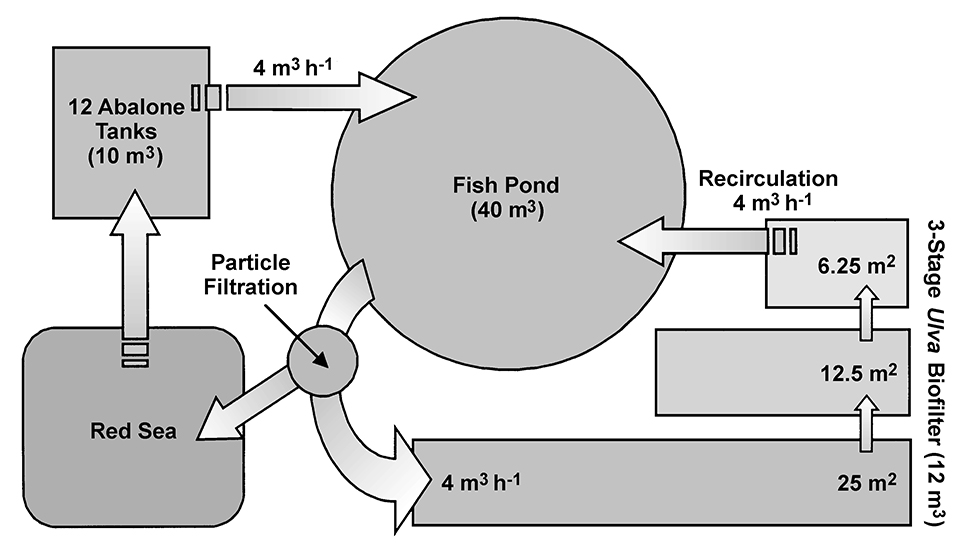

The core unit of the system (Fig. 1) contained an intensive 40,000-liter fish tank, made of tough plastic foil mounted on a metal frame and supported by a concrete base that was stocked with 500 kg of gilthead sea bream. It received seawater previously used in a large shellfish (abalone and sea urchin) rearing unit and an equal amount that previously recirculated through the seaweed biofilter.

Effluent treatment

Because this was the first time that this water reuse was tried on a large scale, only 50 percent of the fish tank effluent was biofiltered and recirculated. Before treatment in the biofilter, the effluent was mechanically screened for particles larger than 0.5 mm. Because abalone needs a very high rate of clean water exchange, the shellfish unit was not included in the recirculating loop. However, both abalone and sea urchin were fed on seaweed produced in the biofilter, which improves system sustainability by increasing nutrient uptake efficiency.

The biofilter was built similarly to the fish tank, with plastic foil and a metal frame. A central pipe along its bottom supplied a continuous stream of air bubbles that maintained the seaweed in suspension. Tank outflows were covered with 0.5-cm plastic mesh to avoid biomass loss. Seaweed harvests were facilitated by a drainage system discharging into a large concrete box below ground level.

Nutrient removal efficiency

When supplied with a higher amount of nutrients, Ulva lactuca removes quantitatively more nutrients (grams per m2 per hour) but at a lower efficiency ( percent). Therefore, either high removal rates or efficiencies can be achieved, but not both at the same time. And when aiming for high removal efficiency, the protein levels of the produced seaweed tend to be low.

To address this, the biofilter included several stages with a 50 percent size reduction between each of the three units. Water purification increased after treatment in each algae tank, but the residence time in each subsequently smaller tank was reduced, which increased the availability of ammonia to units downstream. High removal rates can be achieved in each tank, while keeping high filtration efficiency in the biofilter and protein levels optimal.

Ammonia removal and light

Ammonia removal by seaweed has been reported to be partially light dependent, with the highest uptake occurring during times of strongest solar irradiance. To take advantage of this, fish were fed to satiation during morning hours, leading to top nutrient excretion during daylight hours.

Water flow rates between the system components and temperatures in each unit were measured automatically. After an initial determination of peak times, weekly ammonia samplings plus measurements of dissolved oxygen and water pH were done every six hours.

To preserve water heat and reduce the growth of unwanted algae, the fish tank was covered with a greenhouse like those typically used in intensive desert aquaculture in Israel. The seaweed biofilter unit was only covered with a transparent greenhouse during the winter, when night time air temperatures dropped to as low as 5 degrees C.

Nutrient flux

The biofilter successfully maintained an adequate nutrient flux in all three tanks. It produced high protein level U. lactuca (34 percent dry weight protein ±8.4 SD) at a yield of 117 grams per m2 per day (±23 SD, fresh weight) in all three tanks. This is equivalent to a weekly production of about 36 kg of high quality seaweed. The amount of this seaweed can support the production of up to 3 kg of abalone (FCR 12:1).

During daylight hours, the biofilter removed the maximum ammonia concentrations of 3.2g (±0.6 SD) per hour and with an efficiency of over 95 percent. When there was no light available, these levels dropped but were still considerable, with a minimum removal of 1.1g ammonia per hour (±0.4 SD) and an efficiency of more than 45 percent at night. By recirculating only 50 percent of the fish tank effluent through the biofilter, the input of ammonia to the environment was reduced by over 30 percent.

System naturally self-buffered

As anticipated, peak ammonia excretion by the morning-fed fish coincided with maximum seaweed ammonia removal. Concentrations of the toxic compound in the fish tank remained within safe limits at all times. Due to the recirculation of more efficiently purified water at the times of highest ammonia excretion in the fish tank, the midday-afternoon peak that is common in intensive fish tanks occurred on a reduced level.

CO2 uptake by Ulva through daytime photosynthesis coincided with increased fish respiration and production of CO2 after feeding and during higher daytime activity, thus maintaining pH levels in the fish tank within safe limits in regards to ammonia toxicity. Similarly, the increased oxygen demand by the fish was partially covered by the photosynthetically generated, supersaturated oxygen levels in the recirculated water.

Greenhouse use

Significant amounts of heat were lost in the three shallow biofilter tanks before being covered with the greenhouse. After covering the biofilter in January, higher ambient air temperature and an exclusion of convection resulted in heat gain.

Consequently, by recirculating this warmer water, the fish tank temperature was raised substantially above influent temperature from the shellfish unit and seasonally normal levels. Unfortunately, the large scale of the experiment prevented any replicates and it was not possible to test whether this raise in temperature led to a comparably faster growth of fish and seaweed.

Conclusion

Fish and seaweed have a co-productive effect on each other, because they are heterotrophic and autotrophic organisms (i.e., consumers and producers), respectively, and each utilizes the other’s “waste.” This approach improves use of resources, water quality and the sustainability of the operation, reduces any impact on the environment, and may also be applied to other aquaculture species. Recirculation reduces the introduction of pathogens and fouling organisms and the conversion of excess nutrients into high-quality seaweed biomass recoups the cost of biofiltration. Additional profits can be generated by sale of the seaweed for abalone culture or human consumption. We believe – after operating the system with 50 percent recirculation – that higher water volumes can be recirculated through a larger seaweed biofilter, to further reduce water use and pumping costs and increase seaweed production.

(Editor’s Note: This article was originally published in the February 2003 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Andreas Schuenhoff, M.Sc.

Universidade do Algarve

FCMA

Campus de Gambelas, 8000-117

Faro, Portugal[101,100,46,98,101,119,64,102,102,111,104,110,101,117,104,99,115,46,97]

-

Muki Shpigel, Ph.D.

National Center for Mariculture

Eilat, Israel -

Ingrid Lupatsch, Ph.D.

National Center for Mariculture

Eilat, Israel -

Arik Ashkenazi

National Center for Mariculture

Eilat, Israel -

Flower Msuya

National Center for Mariculture

Eilat, Israel -

Amir Neori, Ph.D.

National Center for Mariculture

Eilat, Israel

Tagged With

Related Posts

Health & Welfare

Double duty: Seaweed provides both biofiltration, marketable product

Most seaweed species that function as biofilters for finfish aquaculture have little market value, so produced biomass remains a byproduct of biofiltration.

Responsibility

Integrated multi-trophic aquaculture, part 2

Regulatory frameworks and financial incentives may be required to fully realize the benefits of integrated multi-trophic aquaculture systems.

Responsibility

Lean and green, what’s not to love about seaweed?

Grown for hundreds of years, seaweed (sugar kelp, specifically) is the fruit of a nascent U.S. aquaculture industry supplying chefs, home cooks and inspiring fresh and frozen food products.

Responsibility

Biofilter start-up problems? Just add sugar!

One way to jump start biofilter operation is by adding sugar, which can provide sufficient organic carbon to neutralize the ammonia-nitrogen produced.