Cost-based decisions vary for hatchery operators

Some of the questions most often asked our laboratory about larval shrimp nutrition include which diets are best and how should they be fed? Like most questions concerning shrimp larval culture, there are no simple answers that can be applied to all hatcheries, universally.

Formulated diets are generally fed to shrimp larvae, starting with the protozoea stage and fed through the PL7-8 stages. Presently, several commercial diets are on the market and most perform well. They almost always recommend to be fed supplementary to the feeding of traditional live diets such as algae, yeast, and artemia. Supplemental diets serve two functions: first, they reduce the cost of feeding by replacing the more expensive “natural food”; and second, they ensure that the nutritional requirements of the larvae are met.

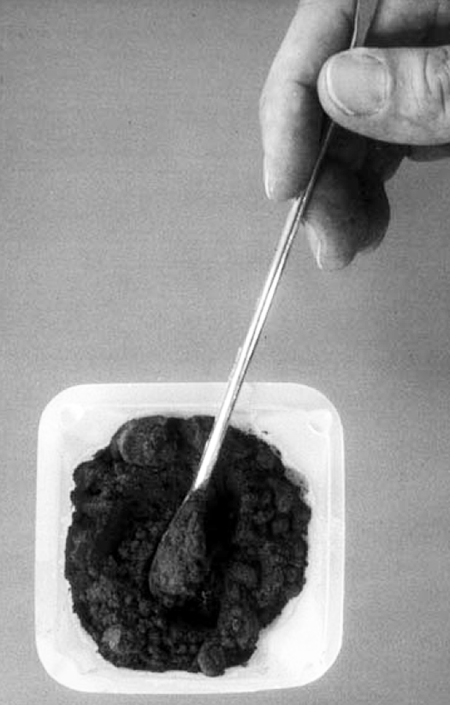

The majority of the diets on the market are “dry diets,” packaged under vacuum or in nitrogen filled cans or pouches. These diets are produced in a range of particulate sizes that best fit the feeding habits of the larval stages for which they are intended. Although the sizes of particles may vary from one manufacturer to another, the following is a good representation: protozoea diets are less than 50 μ, mysis 50-100 μ, PL1-4 100 to 150 μ, and PL4-8 150 to 250 μ.

The crude protein in most of the commercial larval diets range from about 42 to 48 percent. Fats are in the range of 12 to 16 percent, fiber is less than 5 percent. Carbohydrates are normally not listed. The digestibility of proteins and the amino acid composition are more relevant to survival and growth than is the percentage of crude protein. It is important that the lipid portion of the diet contain sufficient levels of highly unsaturated fatty acids. A good diet also contains cholesterol and a phospholipid such as soybean lecithin. Supplementation with a complete vitamin and mineral premix is also a requirement.

Over the past couple of years larval diets in liquid form have gained popularity. At least three commercial companies, Cargill (LiquiLife), Zeigler Bros. Inc. (E-Z Larva) and Epicore Networks, Inc. (Epifeed Liquid) are now marketing liquid diets. They are generally easier to feed and foul the water in the tanks less than dry diets, but they are also more expensive to feed.

While artificial diets make a valuable contribution to the success of larval culture they are not a complete replacement for natural food. However, when used as supplements to natural food, they can increase both survival rate and growth, as compared to the feeding of natural diets (algae and artemia) alone.

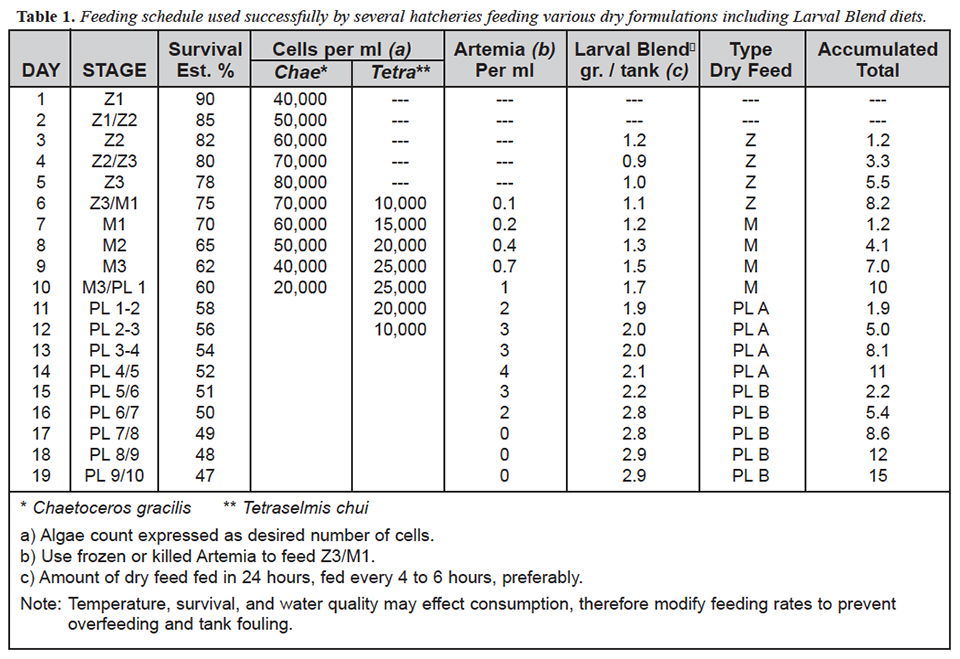

The greatest problem that I have encountered with using formulated diets has been in overfeeding and allowing the uneaten feed to accumulate in the bottom of the tank. The uneaten food provides an excellent substrate for fouling bacteria such as Leucothrix and epiphytes such as Epistylis or Zoothamnium. The dissolved organics also contribute to the accumulation of ammonia and nitrite. As an example Table 1 has been used successfully by several hatcheries feeding several dry formulations, including Larval Blend® diets for which this table was developed. However, this table should not be used to supercede the recommendation of the manufacturer.

Determining which diet to use on a cost-benefit basis should be a high priority with the hatchery manager. The design of the studies is important, making sure that the data obtained provides information that is statistically valid. However, a hatchery selling its postlarvae to other shrimp farms may make the decision on what constitutes the most cost effective diet on a slightly different basis than a hatchery integrated into a large farming (grow-out) operation.

The objective of an independent hatchery may be to produce the largest postlarvae possible in the shortest amount of time, while an integrated hatchery may more closely evaluate the cost of producing postlarvae. If the higher cost of producing larger postlarvae is not compensated for at harvest of grow-out ponds, the integrated hatchery may be reluctant to bear the extra expense. On the other hand, a farmer may be reluctant to purchase postlarvae that he considers small or less active. In reality, a couple of days in a fertile pond or nursery may compensate for a less robust animal, and little or no difference may be seen in size or survival by the time the shrimp are harvested.

(Editor’s Note: This article was originally published in the February 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Rolland Laramore, Ph.D.

Technical Director

Aquatic Animal Health and Shrimp Nutrition Laboratory

Harbor Branch OceanographicInstitution

Ft. Pierce, FL USA

[116,101,110,46,116,101,110,117,115,64,104,108,98]

Related Posts

Aquafeeds

Barnacles to shake up live feeds for aquaculture?

Norwegian startup Planktonic AS believes that it has hit upon a viable alternative to traditional live diets in the form of nauplii from barnacles.

Health & Welfare

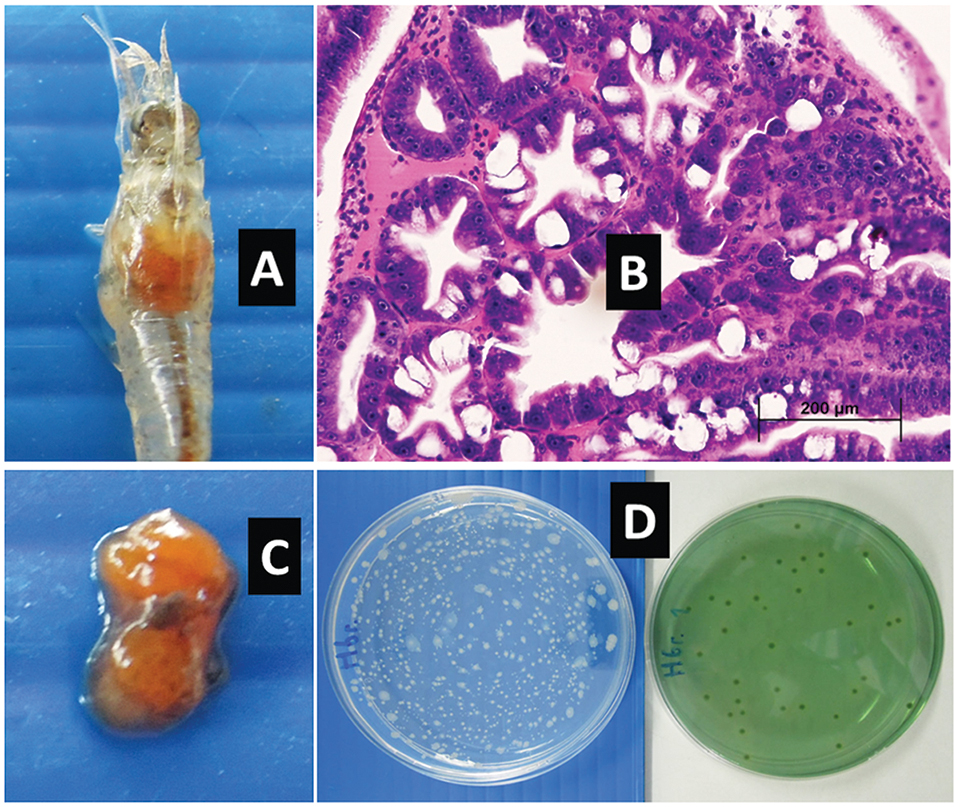

Hepatopancreas colors predict survival of shrimp to EMS

Monitoring of Vibrio bacteria in shrimp larvae determined a relationship among hepatopancreas color, bacteria concentration and signs of early mortality syndrome.

Health & Welfare

Cost-effective biosecurity crucial for shrimp farming

Many shrimp producers give only perfunctory attention to routine biosecurity at hatcheries and farms. A cost-effective biosecurity program for farmed shrimp requires reliable diagnostic tools to make timely decisions to control or exclude pathogens.

Aquafeeds

Aquaculture Exchange: Dr. Tom Zeigler

The World Aquaculture Society’s latest Lifetime Achievement Award recipient reflects on 50 years in the business of producing high-quality, nutritious feeds for the poultry, livestock and aquaculture industries.