The global seaweed industry

Agar and carrageenan are phycocolloids or marine gums which are synthesized by red seaweeds, principally those of the genera Gracilaria and Eucheuma. Phycocolloids are valued for their unique gelling, stabilizing, and emulsifying properties. They are commonly used as ingredients in cosmetics, tooth paste, ice creams, dairy products, and diverse biotechnology products.

Global production of carrageenan amounts to about 25,000 metric tons (MT) per year, which requires approximately 400,000 MT of red seaweeds as raw material. This generates annual revenues of $240 million U.S. Processing plants in Denmark, France, the US, and Spain currently control this market, but there are emerging industries in Southeast Asia and Chile. Close to 80 percent of the raw material required for carrageenan production comes from tropical species of Eucheuma (Kappaphycus alvarezii and E. denticulatum) farmed in Indonesia, the Philippines, and Tanzania.

Successful seaweed farms in the phycocolloid industry have been closely linked with the sustainable development of coastal communities, mainly in the Indo-Pacific and East Africa, where Eucheuma farming has created more than 500,000 direct jobs and about 6,000 ha under cultivation. The domestication and establishment of Eucheuma farms has allowed new settlements in remote islands of the Pacific. Annual world production of food-grade agar is approximately 7,500 MT, with major processing plants in Chile, Japan, Spain, Taiwan, Korea and Morocco, and sales over $130 million U.S. Most of the raw material for agar production comes from Gracilaria sp. farms in Chile, Taiwan and Indonesia, where 72,000 MT of these seaweeds are produced, and with current FOB prices of around $1,000 U.S. per MT. Additional material comes from natural beds of species of Gelidiales (Gelidium, Pterocladia and Gelidiella spp.) from Spain, Portugal, Morocco, and Japan.

Ecological considerations of seaweed farming

The introduction of exotic species has become a controversial issue between environmentalist groups and aquaculturists, considering the threats and risks to the environment and biodiversity. This has led us to adopt a responsible Seaweed Mariculture Program in Venezuela. Information about the negative effects of intentional introductions of seaweed for aquaculture purposes is scarce. There was a major concern with the introduction of the giant kelp Macrocystis pyrifera, an alginate producing species from the Pacific coast of the Americas, to Europe. However, this project was canceled due to the invasion risks of such a large plant, which is able to grow to more than 15 meters in length.

Another environmental threat has been the accidental introduction of exotic species together with crops of commercial interest. This happened when the Japanese oyster Crassostrea gigas was introduced for mariculture purposes to the Pacific coast of the United States and Canada, bringing along Sargassum muticum and Codium fragile subs. tomentosoides, two macroalgae that eventually caused severe environmental disturbances to the surrounding areas.

On the other hand, Kappaphycus alvarezii and E. denticulatum have already been introduced into at least 12 countries, including regions and remote islands of the Pacific, with seaweed farming as the main purposes. Only five countries have developed projects that are currently at the commercial level. The failure of most of these attempts has been due to the particular environmental requirements of these strains, which are limited by several factors, including light availability, water exchange, salinity ranges, nutrient levels and predators (grazers).

In the Caribbean and South America, successful introductions are already reported in Cuba and Brazil, with very promising results for the establishment of seaweed industries. But these initiatives have faced several environmental problems. In Cuba, intensive grazing by fishes has made the establishment of farms around coral reef areas very difficult. In Brazil, the low temperatures have limited the growth and development of Eucheuma farming in the state of Sao Paulo during the winter months.

Seaweed farming as an alternative – Venezuela as a case study

In Venezuela, we have searched for new alternatives for sustainable development, through the implementation of rural mariculture programs aimed at assisting artisanal fishing villages, particularly in the Araya Peninsula and the nearby islands of Coche and Margarita located on the country’s northeastern coast. These coastal communities traditionally report high unemployment rates and malnutrition, infant mortality and illiteracy. Excluding the artisanal and subsistence fisheries, only very small-scale farming and limited animal husbandry are practiced, due to a general lack of funding and basic services, such as electricity, running water, transportation and medical assistance. In Araya Peninsula and Coche Island, salt works and artisanal fisheries have been the only economic activities since colonial times. However, the salt industry has suffered severe changes since its privatization in 1995, increasing the unemployment rates.

Paradoxically, this is one of the richest regions of the Caribbean, where the coastal waters are affected by a seasonal upwelling phenomenon caused by the trade winds and the ocean currents. This is clearly shown by the low temperature, high fertility, and high productivity rates of the marine flora, particularly in areas where seaweed are grown for the phycocolloid industry. In Venezuela, marine algae thrive naturally and have been known locally as “limo” or “marite,” a pejorative term that means garbage or weed of no use or value.

Seaweed farming trials started in the NW coast (Paraguaná Peninsula) in 1986 following a previous study on the quality of some species of Gracilaria and their potential as a phycocolloid source. These preliminary experiences were an incentive to design a pilot plant for agar production. In 1989, the company Geles del Caribe (GELCA) began to evaluate the potential to establish a phycocolloid industry there, based on a rural mariculture program in the Araya Peninsula. During this pioneer work, several aspects of seaweed farming and industrial processing were studied.

After five years of research, an integrated program involving the coastal communities was developed for the fishing villages of the north coast, where several families, including women and young people, worked in the marine farms. Some of the harvested raw material was used in a pilot processing plant located in the city of Cumaná, and the rest was exported to factories in Namibia, Ireland, and Chile for food grade agar. Unfortunately, this program was canceled in 1994 due to the tight market control exercised by the Chilean industry and the lack of a better quality crop. Gracilariopsis tenuifrons (G. lemaneiformis) is a fast growing strain but produces a below average food grade agar, and therefore GELCA was unable to find a market for the raw material.

Introduction of Eucheuma

In May 1996, 5 kg of Kappaphycus alvarezii and Eucheuma denticulatum were shipped by air cargo from a commercial farm located in the Danajon Reef, Sea of Bohol in the Philippines, where they have been grown vegetatively for at least 25 years. After their arrival, the algae were quarantined for a period of six weeks, treated with antibiotics, and kept in a tank with a closed circulating water system. During this period, we tried to avoid the proliferation of exotic and undesirable organisms and epiphytes, including other species of seaweed, microalgae and animals. We also checked for the absence of sexually reproductive structures, avoiding the dispersion and settlement of spores, which could eventually cause the competition and displacement of benthic organisms. After this period, the plants were placed in a mesh bag in the sea for one week, then cut into smaller pieces and tied to ropes at the Araya pilot farm.

Field observations during more than three years have shown that both strains have been innocuous in the different environments where they have been cultivated. The absence of spores, attachment, or floating structures has limited their dispersion and settlement beyond the farms. Some algal material has been able to grow and establish temporarily in a shallow sandy area; however, this population could only be maintained by the influx of thallus fragments coming from the marine farms. Water depth is the single physical factor that most limits the growth and dispersal, with a maximum of 20 m in the clearest waters.

Among the major ecological limitations are the presence of herbivores and epiphytes from coral reefs, particularly species of parrot (Scaridae) and surgeon (Acanthuridae) fishes and the white sea urchin Litechinus variegatus. In a recent study conducted at an Eucheuma farm in Coche Island, ropecultivated K. alvarezii was found to be an ideal substrate and shelter for more than 22 species of fishes (mainly juvenile stages) and 35 of invertebrates, including larval stages of crustacean, mollusks, solitary and colonial ascidians, sponges, sea urchins and holothurians. These results showed that Eucheuma thalli have a higher diversity index of species when compared with control areas without any farming activity.

Regarding the possible shading effect that could be caused by K. alvarezii cultivation on seagrass communities, we have found significant differences, even though the seaweed are grown above large beds of Thalassia testudinum. This is probably due to the high light available in depths < 2 meters, the size of the mature implants and the length of the cultivation period (which is usually less than six weeks). On the other hand, seagrasses are of vital importance in the recycling of nutrients and heavy metals required for the optimal growth of Eucheuma denticulatum, as shown in a field experiment in the island of Zanzibar, East Africa.

In 1996, a new company called Cultivos & Biotecnología Marina (BIOTECMAR) resumed seaweed farming activities in the Araya Peninsula, reactivating a pilot farm along with several cultivation trials in the nearby islands of Coche and Margarita. In order to diversify the supply of raw material for the phycocolloid industry, two species of Eucheuma were introduced from the Philippines in April of that year. These strains, Kappaphycus alvarezii and Eucheuma denticulatum, have traditionally had great demand in the carrageenan industry, particularly in Europe, the U.S, and more recently in SE Asia. K. alvarezii, known commercially as Eucheuma cottonii, supplies more than 80 percent of the raw material required for this important colloid.

Farm productivity and economic returns

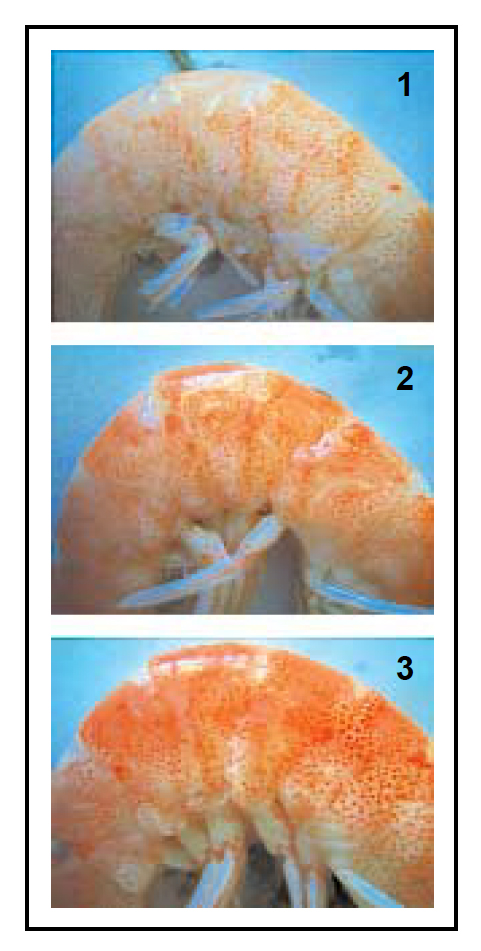

Eucheuma cottonii (K. alvarezii) is the only species currently farmed commercially in Venezuela, due to its market demands by the carrageenan industry in Europe and the U.S. Small cuttings of 80 to 100 grams. are tied to ropes with plastic straws and attain a final biomass of 600 to 1,000 grams. Harvesting takes place every 40 days, with mean productivity rates close to 2.5 MT per month, equivalent to 30 MT per hectare per year. The income generated by the seaweed farmers has always been above the minimal rural wage, in a region where unemployment rate is traditionally over 40 percent. The cultivation area depends on the input and effort of the farmers, but our experiences have shown that four to five people (usually members of the same family, including women and young people) could operate a one-hectare plot. This is done on a contract basis with a local integrating company, which buys the sun-dried algae at a fixed beach price of around $0.30 U.S. per kg.

The harvested material is bailed and shipped to carrageenan markets in Europe (and there are unfulfilled demands for this material in the U.S., Brazil, Chile and Japan). Soft loans are provided to each family interested in starting a new farm, and all materials and equipment are provided. The cost of each 1- hectare farm, using the bottom monoline method of wooden stakes and polypropylene ropes, is about $6,000 U.S. ($1 U.S. = Bs. 660 as of mid-February 2000). Each 1-ha farm includes forty modules of 250 square meters (100 ropes 5 meters long) each. This also includes a sheltered area for seeding the ropes in the beach, a small warehouse for storage, solar dryers, and basic working equipment such as scales, diving masks, machetes, knives, a net pen for seedling storage in the water, and a small rowing boat (locally known as “cayuco”). We have estimated the potential for the sustainable development of these systems to be about 200 ha, considering available areas in the States of Sucre, Nueva Esparta (Margarita and Coche Islands) and the Paraguaná Peninsula on the NW coast. Development of this potential could create around 1,200 to 1,500 new jobs, with an annual production of 6,000 MT of raw material for the international phycocolloid industry.

Conclusion

Pilot cultures of K. alvarezii and Eucheuma denticulatum in the Araya Peninsula and Coche Island during more than four years have produced excellent daily growth rates in the range of 4 to 9 percent. This is equivalent to 30 to 35 MT per hectare per year, compared with similar values in commercial farms of Indonesia, the Philippines and Tanzania. The international prices and demand of K. alvarezii have considerably increased in the last three years due in part to the economic uncertainties in Southeast Asia, where more than 95 percent of the raw material is produced. In 1997, K. alvarezii (E. cottonii) FOB prices in Europe were around $600 U.S. per MT. During 1999, Venezuela started commercial operations, exporting farmed E. cottonii to France and Denmark with a mean FOB price of $720 U.S. per MT. Several industries based in Europe and the U.S. are expecting a sustainable supply that could be on the order of at least 2,000 MT per year, equivalent to the operation of about 100 ha. This will create more than 600 direct jobs in the states of Sucre, Nueva Esparta and Falcon, some of the poorest regions of the country.

In order to achieve these goals, we need resources and assistance for development, which is usually the most expensive and difficult part of seaweed farming. This includes financial aid, such as soft loans to support the farmers and their basic requirements. As mentioned earlier, the cost of a farming unit operated by four to six family members is about $6,000 U.S., including technical assistance and training. Additionally, we require a legal framework that would allow the establishment and management of marine farms, including ownership rights and long-term leasing to protect the farmers and integrating companies from other conflicting activities such as tourism and urban development. After all these years, our farming experiences have led to the establishment of a growing seaweed industry with important impacts on the socioeconomic structure of coastal communities. Among the most relevant of these changes is the active participation of women, expanding on their limited and traditional role as housewives. If all these factors are considered, seaweed farming could be an important alternative and source of income to the coastal communities of many developing nations. The experiences in Venezuela prove it can be done.

(Editor’s Note: This article was originally published in the April 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Raúl E. Rincones

Fundación Agromarina

P.O. Box 377

Porlamar Isla de Margarita, Venezuela[109,111,99,46,108,105,97,109,116,111,104,64,97,110,105,114,97,109,111,114,103,97]

Tagged With

Related Posts

Responsibility

Integrated multi-trophic aquaculture, part 2

Regulatory frameworks and financial incentives may be required to fully realize the benefits of integrated multi-trophic aquaculture systems.

Responsibility

Seaweed aquaculture provides diversified products, key ecosystem functions, part 2

Seaweed remains a relatively untapped resource with potential as edible food, feed ingredients, cosmetics, agrichemicals, biomaterials and bioenergy molecules.

Responsibility

Seaweed farming offers avenue toward greater food security

Seaweed farming has both proven history and huge potential. Large-scale farms could produce raw materials for biofuel, aquatic feeds and human consumption.

Aquafeeds

Enteromorpha tested as shrimp feed ingredient

With vitamins, minerals, carotenoids and higher protein content than other species, Enteromorpha is a superior seaweed choice and a potential shrimp feed ingredient.