Goal is to efficiently extract shrimp from the drain and chill them to near freezing temperature within seconds after harvest

Shrimp is a delicate and highly perishable product. Once quality is lost, no amount of manipulation can restore it. The most demanding market for premium quality is the European heads-on market. Shrimp that meet the standards of the European market will be judged as first-quality anywhere in the world. The following describes a harvesting system that consistently yields quality product suitable for that market.

Basic steps in shrimp harvesting

The process of harvesting a shrimp pond is simple in concept. The pond is most often drained through a net, which captures the shrimp as they leave the pond with the draining water. Following capture, shrimp are either manually or mechanically lifted out of the drainage area, chilled with ice, and transported to the processing plant. This can be a major task considering that a pond may contain five to 40 tons of shrimp that must be harvested in a few hours, chilled from 30 degrees C to near freezing, and packed without damage.

In a well-designed pond that has been skillfully drained, little or no shrimp remain on the pond bottom to be picked up by hand. Shrimp that are picked from the pond bottom do not meet the highest quality standards due to delayed chilling and to mud embedded in gills and joints between tail segments. Thus, the major challenges at harvest are to minimize the quantity of shrimp left on the pond bottom, immediately chill shrimp to near freezing, and pack them in a manner that avoids damage.

Pond design

The first prerequisite of a successful harvest is pond design and construction. The bottom must be sloped to drain completely without leaving large puddles, where shrimp tend to remain. Cylindrical drainage culverts have diminishing cross-sectional area as the pond level drops. Culverts should be installed slightly below the level of the pond bottom to help avoid slow drainage as the water level decreases at the end of the harvest.

Shrimp behavior

Shrimp behavior varies with a number of factors such as species, lunar stage, temperature, and molt stage. As a general rule, shrimp do not begin to move toward the pond outlet until most of the water has drained from the pond. Consequently, it is a common practice in large ponds that require more than six hours to drain to slowly reduce the pond level by about 50 percent the day before harvest.

Once the harvest begins and shrimp begin to move toward the outlet, the emigration process tends to accellerate as long as the pond continues draining. This can result in several tons of shrimp reaching the outlet over the course of a few minutes. If the harvesting crew gets overloaded and the drainage process must be interrupted, shrimp tend to settle back to the bottom again.

To re-establish the emigration generally requires considerable drainage of water. As a result, the pond may completely drain before many of the shrimp have had an opportunity to exit. It is important to maintain continuous water flow throughout the harvest process. Skillful harvesting reduces the number of interruptions and results in less than 1 percent of the shrimp remaining on the pond bottom.

Importance of chilling

Shrimp begin to deteriorate within minutes after death at normal pond temperatures of 25 to 30 degrees C. Initial damage is caused by digestive enzymes released from the hepatopancreas (liver-like organ in the head). At elevated temperatures, these enzymes quickly break down tissue at the junction of the head and tail.

This makes the interior of the head darken in color and the attachment of the head with the tail loosen and sag, which is unacceptable to the European market for head-on shrimp. Some European buyers simulate the conditions in their seafood markets by taking a frozen block of shrimp out of its packaging and leaving it at room temperature for four hours. If the heads turn black or loosen, the product is rejected.

Shrimp digestive enzymes also cause protein destruction, which reduces product weight and may effect meat texture. High temperatures also promote chemical and bacterial decomposition. These enzymatic, chemical, and bacterial processes can be slowed to a standstill by immediately reducing the body temperature to near freezing.

It is important to handle shrimp gently during packaging into containers with ice. Rough handling can break appendages or bruise the head, which also limits acceptability to certain markets.

Timing the harvest

In the hot tropical sun, temperatures at the bottom of a drained pond can exceed 40 degrees C. At these temperatures, stranded shrimp can begin to spoil before they can be picked. To avoid this problem, harvests are most often conducted during the night with the intention of completing the process by early morning, when lighting is available for hand picking but temperatures are still moderate enough to avoid rapid spoilage.

In areas where ponds can be drained only at low tide, harvests must be timed to reach the final stage of drainage at low tide, or sufficient pumping must be available to quickly remove all the water.

Mechanical harvesting systems

Just as combines and tractors have long harvested agricultural row crops, shrimp pond harvesting is also becoming more mechanized. There are several types of mechanical harvesting systems including Archimedes screw systems, reciprocating vacuum/pressure pumps, and recessed impeller pumps.

Each of these has advantages and disadvantages. For example, the screw system has many advocates, because it is a simple mechanism that is easily repaired on the farm. It requires only a small electric motor, because it is designed to elevate only shrimp, not water. Pump harvesters require larger motors to move water and shrimp, but the watermoving capability can be a useful tool. Our experience has been with recessed impeller pumps, so we will focus our discussion on these systems.

Shrimp collecting funnel

The vast majority of water drained from a pond is not pumped by the harvesting system. It simply drains through a funnel-shaped net or cage, which concentrates the shrimp, while the majority of the water passes through the sides of the net or cage. The continual flow of water directs shrimp toward the cone of the funnel where a submersible pump or suction hose is located. In SouthTexas, we typically use a stainless-steel collecting funnel connected to a submersible harvesting pump. A tripod is used to lower the funnel into the harvest box using a block and tackle and “come along” (hand winch).

The funnel measures 2 ft deep by 4 ft wide by 2 ft long (60 x 120 x 60 cm), and fits over the culvert outlet on the discharge side of the harvest gate. A rubber gasket is positioned between the harvest box and the funnel to assure a complete seal. A jack is used to hold the funnel tightly against the concrete harvest box. The cable from the tripod to the funnel is kept in place for support.

Recessed impeller pumps

Recessed impeller pumps create a water current, which moves the shrimp upwards to a de-watering tower without the impeller touching it. These pumps have been used for many years for applications ranging from tomatoes to live trout. Marine Culture Enterprises, the super-intensive raceway project developed in Hawaii during the 1980s, used these pumps to transfer juvenile shrimp from one raceway to another during the grow-out process.

Recessed impeller pumps are hydraulically driven by a separate electric, diesel, or gas-powered motor. The pumps are available in submersible and non-submersible designs. The non-submersible design tends to lose its prime periodically, which can be problematic during peak harvest periods. Both in Texas and Belize, the submersible design is used.

De-watering tower

The mixture of shrimp and water is pumped from the collecting funnel via a 6- to 8-ft- (15- to 20-cm-) diameter hose to a de-watering tower at the top of the levee. The dewatering tower consists of a funnel-shaped vessel, which decelerates the water velocity from the hose and directs the water and shrimp over an angled grating. The water drains through the grating, while the shrimp tumble over it.

The result is that clean, live shrimp with a minimum amount of water are delivered to the top of the levee, where they can be further processed or dropped directly into insulated boxes with ice. The discharge water from the tower can be directed either to the drainage ditch to speed up water removal from the pond, or back to the pond to replenish oxygen or conserve water needed by the remaining shrimp.

Insulated totes

We prefer to discharge shrimp from the de-watering tower directly into an ice slurry within 1-cubic-meter insulated boxes. We prefer boxes without drainage plugs due to danger of unintentional draining, which can result in spoilage if the product is stored in boxes for several days.

To minimize the number of workers needed during harvest, boxes are pre-filled with about 21 in (53 cm) of ice slurry using a mark on the inside of the box. Slush ice is ideal for this purpose (see article, page 55). Another option is to pass about 1.5 bars of block ice through a flaking machine and then add water to create a slurry. If bacteria are a problem, chlorine can be added at low levels to the ice slurry. For the European market, sodium bisulfite is also added to the slurry to prevent blackening within the head.

During harvest, shrimp from the de-watering tower are discharged directly into the boxes, which results in immediate chilling to near freezing. The traditional system of alternately applying a layer of shrimp and a layer of ice provides nearly equivalent chilling, if it is done properly. However, if a particular scoop of shrimp is too large or a scoop of ice is too small, then hot spots can result. These hot spots result in product deterioration.

The ice slurry system provides consistent chilling every time. Also, crushing is avoided due to suspension of shrimp in the ice/water slurry. Each box is filled to about 4 in (10 cm) from the top, whereupon it contains about 800 lbs (360 kg) of head-on shrimp.

Transport, storage, and weighing

Various methods can be used to transport the insulated boxes to and from the ponds. To operate at the top of the pond levee, inexpensive low-riding trailers with wide tires are sometimes used. Six to eight boxes can be hauled per trailer. In advance of a harvest, several trailers can be connected together like railroad cars under the discharge from the de-watering tower.

As the first totes are filled, the chain of trailers is simply pulled forward by a truck or small tractor. In Belize trailers have been assembled that carry three insulated boxes, and another three boxes are placed in the back of the truck that pulls the trailers.

Harlingen Shrimp Farms harvests beside a road that can handle 18-wheeled trailers that can pack 22 insulated boxes per trailer. In advance of a harvest, several trailers of insulated boxes pre-filled with ice slurry are dropped off at the pond. A pallet jack is used to lift and wheel each insulated box to the door of the trailer, where a fork lift puts it in place to be filled with shrimp.

Once at the processing plant, boxes are lifted off the trailers by forklift. The shrimp can be held for several days in the totes without loss of quality if the excess water is siphoned off using a PVC pipe and replaced with clean water and ice. When the plant is ready to receive the shrimp, the boxes are unloaded into the thaw tank using a forklift to load a simple counterbalanced dumper.

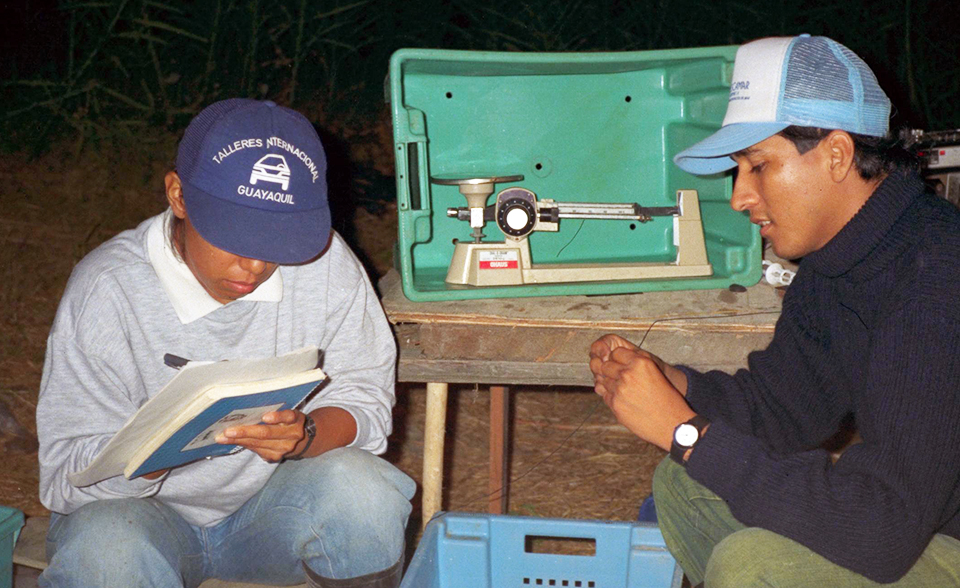

Final accounting of the weights and sizes of shrimp occurs at the processing plant. If a third-party processor is used, it is prudent to provide a trusted farm employee to oversee the weighing process.

Labor requirements

Mechanical harvesting systems reduce labor requirements for pond harvesting by at least 50 percent. For example, Harlingen Shrimp Farms utilizes six people to harvest ponds that yield up to 40 tons each. This includes a supervisor, two workers for the pallet jack, a forklift operator, and two workers operating the harvest machine.

Optional post-harvesting steps

In some cases, it may be beneficial to conduct additional processing at the pond bank. This can include:

- Dipping live shrimp in sodium bisulfite to reduce blackening of the head for head-on shrimp.

- Removing crabs, fish, and trash.

- Selecting the largest animals to be used as potential broodstock.

These processes can easily be incorporated by addition of a conveyor following the de-watering tower.

Conclusions

Mechanical harvesting systems have been developed to assure consistently top quality by efficiently extracting shrimp from the drain and chilling them to near freezing temperature within seconds after harvest. These systems have the capability of handling large volumes of shrimp over a short period of time with minimal labor. By avoiding the need to stop water flow during harvest, these systems also minimize the number of shrimp left in the pond to be hand picked. The process involves screening shrimp from the drainage water, pumping them to the dewatering tower where they are separated from pond water, and discharging them into an ice slurry.

(Editor’s Note: This article was originally published in the August 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Les Hodgson

Marco Sales, Inc.

Brownsville, Texas USA[109,111,99,46,108,111,97,64,112,109,105,114,104,115,115,109]

-

Keith Gregg

Harlingen Shrimp Farms, Ltd.

Los Fresnos, Texas USA[109,111,99,46,101,118,114,101,115,117,112,109,111,99,64,119,101,105,118,121,97,98,102,115,104]

-

Robins McIntosh

Belize Aquaculture, Ltd.

Belize[116,101,110,46,108,116,98,64,97,117,113,97,101,122,105,108,101,98]

Tagged With

Related Posts

Health & Welfare

Building a better shrimp nursery, part 1

Shrimp nursery systems offer an important opportunity to increase profits. Properly designed and operated nurseries are highly biosecure facilities to grow postlarvae at very high densities.

Health & Welfare

Harvesting head-on shrimp

EU markets have special requirements for head-on shrimp. Organoleptic criteria are evaluated, including firmness of shell and head, malformations and color.

Intelligence

Ice slurry expands product cooling, preservation options

Ice slurry can provide even chilling of seafood at harvest to slightly above the freezing point and maintain this temperature throughout the cold chain.

Health & Welfare

Culture of Pacific white shrimp juveniles in super-intensive conditions

Results of this study showed that L. vannamei juveniles can be cultured at high densities with adequate survival, growth and feeding efficiency, and with minimal water exchange or full water reuse through recirculation.