Hanging park, long-line facilities near farm capacity

Historical records show that marine aquaculture was practiced in Greece as early as the 5th century B.C., but modern marine aquaculture in the country started about 40 years ago. Following the global trend, it is now a rapidly emerging industry growing faster than any other animal production sector.

Major species in production are the euryhaline finfish species sea bass and sea bream, and the Mediterranean mussel (Mytilus galloprovincialis). The farming of the latter was introduced in the 1970s, but it really boomed as soon as the technological developments of the Italian pioneers in the 1950s were eventually adopted by the Greek farmers in the mid-1980s.

Traditional production

At first, the farming systems adopted by the Greek farmers were the traditional hanging parks cultivation implemented in soft-bottomed, shallow, highly eutrophic near-shore waters. The productivity of such systems is usually very high, ranging 150 to 400 metric tons of live mussels per hectare. As they are quite easy to maintain and to handle production, the systems became very popular and widely expanded.

Typically, a mussel farm of this technology occupies less than 2 hectares and involves mainly the farmer and his family in its management. However, farm development is limited by available space and competition with tourism and urbanization for suitable sites. Farms also raise questions regarding their installation in highly appreciated natural river delta ecosystems.

Long-line culture

As a solution to several constraints of the traditional methods, the long-line floating culture system was introduced for mussel farming to depths over 6 m, thus overcoming the space limitation near shore. The productivity at higher depth is lower – from 100 to 120 metric tons per hectare – and requires a boat for access. On the other hand, the farms can be expanded to occupy larger surfaces, provided that the local trophic status can support the necessary growth rates and maintain quality.

A typical long-line farm covers 100 to 120 meters, with long ultraviolet-resistant polypropylene ropes set in parallel 10 meters apart and suspended from 200-L buoys, which are often second-hand plastic barrels. A pair of 3-metric-ton moorings is typically used to anchor the floating installation to the bottom with the whole farm oriented parallel to the direction of the prevailing currents.

Some long-line farms still use a near-shore site as a support installation for the finishing of the product, spat collection or biofoulant removal by exposing the mussel bunches to the air for a period.

Mussel business

Mussels are ready for the market when they reach 6 cm long, usually at the end of the spring, one year after the harvesting of the seed from the spat collectors. The majority of the final product is exported live to the Italian, French and Spanish shellfish markets.

Mussel farming in Greece supports approximately 1,500 full-time jobs, which reflect mainly self-employment of the mussel farmers and 500 part-time positions during the peak seasons. Another 500 people – the majority of them women – work in the mussel-shucking houses and packing stations.

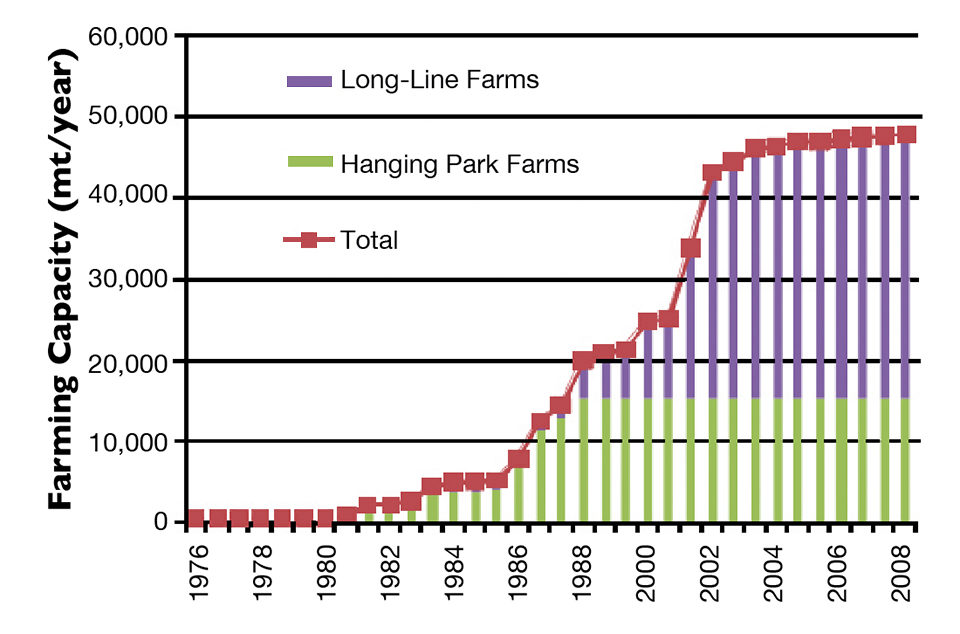

Although the total production capacity is higher (Fig. 1), annual production volumes indicate that total mussel production grew quickly after the year 2000 and reached 23,000 metric tons (MT) of product worth over 10 million euros in 2009. Further expansion of the industry is limited, as few new licenses are being issued, and most of the traditional sites cannot be expanded further.

In the future, mussel farming may increase the industrialization of its production methods and possibly consolidate to take advantage of larger-scale economics. Major goals for the future would be to reduce production costs and establish branding through the introduction of a quality development scheme and enhanced marketing.

(Editor’s Note: This article was originally published in the January/February 2011 print edition of the Global Aquaculture Advocate.)

Authors

-

J.A. Theodorou, M.S.

Department of Fisheries and Aquaculture

Technological Educational Institution of Epirus

G.R. 46100 Igoumenitsa, Greece[114,103,46,112,101,105,101,116,64,111,101,104,116,106]

-

Dr. I. Tzovenis

Department of Fisheries and Aquaculture

Technological Educational Institution of Epirus

G.R. 46100 Igoumenitsa, Greece

Tagged With

Related Posts

Responsibility

A look at integrated multi-trophic aquaculture

In integrated multi-trophic aquaculture, farmers combine the cultivation of fed species such as finfish or shrimp with extractive seaweeds, aquatic plants and shellfish and other invertebrates that recapture organic and inorganic particulate nutrients for their growth.

Intelligence

An emerging shellfish farming industry in Namibia

For shellfish farming in Namibia to continue expanding, industry must better comply with approved sanitation standards. The Namibian Shellfish Monitoring and Sanitation Program, currently in development, will help.

Innovation & Investment

Pioneering U.K. mussel farm channels innovation, ambition

John Holmyard’s family has navigated a complex journey to get their rope-grown mussel farm operational in the waters off southern England. Offshore Shellfish Ltd. has solved the puzzles of bespoke equipment, a perplexing permitting process and the social license to operate.

Responsibility

Lease, seed and repeat: GreenWave’s replicable aquaculture

Don’t call it integrated multi-trophic aquaculture: Former commercial fisherman Bren Smith says polyculture of non-fed species is the future of aquaculture.