Process converts carbon dioxide, nitrogen and phosphorous into protein, and releases oxygen

The search for sustainable fish feed has led innovators to ingredients like soy, peas, wood, rapeseed, insects and even microbes fed natural gas. Now Marissa Cuevas is trying a different feed input: fish output.

Cuevas is the founder and CEO of MicroTERRA, a Mexico-based startup developing systems that use microalgae to turn fishpond wastewater into protein for fish feed. The circular system not only cleans and oxygenates dirty pond water for re-use, but could allow a fish farmer to produce up to 60 percent of their own feed, she says.

“It’s autonomous production on-site,” Cuevas told the Advocate. “The idea is to provide technology so they can be self-sufficient in their fish feed production.”

Cuevas, who has a background as a renewable energy engineer and a master’s degree in sustainability management, came up with the upcycling idea after learning about the impacts of wastewater and agricultural runoff, which can deposit high levels of nitrogen and phosphorous in oceans and waterways, leading to toxic algae blooms, fish die-offs and low-oxygen areas known as dead zones.

“I thought, there must be a way to take those nutrients out of the water and put them back in the soil, because ultimately nitrogen and phosphorous are key to our nutrition,” she said.

From microalgae to fish feed

Cuevas ruled out using kelp or seaweed to capture wastewater nutrients, because of the plants’ long growing time. “Then I looked at the smallest plants in the world – microalgae,” she said.

She developed a system in 2018 for turning wastewater into fertilizer but found there was not enough of a market for the product. Then while interviewing a farmer for her market research, she noticed tilapia tanks on his property.

“As soon as I saw the tilapia tanks, I thought, this is the water we need,” she said. “It was full of nutrients and it was already in the pipeline.”

When Cuevas learned that one of the farmer’s biggest problems was the cost and variability of his fish feed, the lightbulb went off.

“I went back to our CTO and said, ‘Can we do fish feed?’” Cuevas recalled. “She said, ‘of course we can.’”

For Cuevas, the idea “made so much sense,” she said. “By creating a sustainable product out of that wastewater, we’re also replacing fishmeal. The impact on oceans would be even bigger.”

A self-contained system

In 2019, the company launched its pilot project, a 5,000-liter system now operating at a fish farm in Irapuato, Mexico, which produces around 4 kg of fish feed per day.

In the MicroTERRA system, wastewater flows into bioreactors, where it mixes with microalgae. The tiny organisms absorb carbon dioxide from the water, along with nitrogen and phosphorous, converting the nutrients into protein, and releasing oxygen. The cleaned water is returned to the fish pond, while the protein is mixed with other ingredients to create pellets for fish feed.

Technicians can monitor the system remotely with sensors and communicate with the farmer if something needs attention, like adjusting the pH, or opening a valve to circulate water.

Cuevas estimates a 100,000-liter system would cost about $250,000.

“The idea is that because it’s displacing fish feed, the payback period is approximately five to seven years,” she said.

MicroTERRA is focusing on Latin America as a market for the systems, because of the region’s warm climate and abundance of sunlight. With no need for artificial lighting or temperature, “our systems can stay affordable,” said Cuevas.

In addition to selling systems to fish farmers, Cuevas is looking at fish feed producers as a potential market. “Latin American has a huge market not just for fish but also for fish feed,” she said. “They’re already searching for sustainable protein, and I think for them our system could be super interesting.”

The company’s next project, a 25,000-liter system, which will produce an estimated 20 kg of fish feed per day, is scheduled to be deployed in February and March at a tilapia farm in Apaseo el Grande, Mexico.

‘Really intriguing idea’

The company was selected for the 2019 cohort by the Techstars Sustainability Accelerator, a prestigious three-month mentoring and business development program backed by The Nature Conservancy. The program seeks to support viable businesses that are addressing top environmental challenges, including protecting land and water, providing food and water sustainably, building healthy cities, and tackling climate change, according to Robert Jones, global lead for aquaculture at TNC. The accelerator had been actively seeking aquaculture companies to apply; MicroTERRA was the first to be accepted.

“I think MicroTERRA has a really intriguing idea,” Jones said. The company stands out because it addresses two major challenges facing aquaculture: reducing the environmental impact of effluent, particularly from pond-based systems; and feed sustainability. The concept addresses both challenges in a self-contained system, while also building on the concept of a circular economy and regenerative agriculture, he argued.

“We do need innovations like this to help aquaculture become more sustainable,” Jones said. Particularly intriguing is the fact that MicroTERRA’s system would be beneficial to small and medium-sized pond-based aquaculture operations. “I think that’s very compelling.”

Scaling up

Jones worked with MicroTERRA to address technical challenges around commercialization, including building connections with technical experts to help design studies on feed profiles.

Cuevas said the program helped MicroTERRA transition from R&D to the next phase, and scale up. “Techstars was an amazing experience to grow the business behind the idea,” she said.

The startup’s next step is a fundraising round, planned for the first quarter of 2020. Cuevas also hopes to form a strategic partnership with a fish feed producer. “Ideally we would focus only on the wastewater treatment and transforming it into a sustainable protein and let the experts in the field create the fish feed,” she said.

MicroTERRA has a bright future, Jones said.

“The leadership of the company is very strong. This is a high-energy, enthusiastic, very knowledgeable group of female entrepreneurs from Mexico, who really want to see this done for the good of the planet and think they can make money at it,” he said. “I wouldn’t underestimate the ability of this group to be successful.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Ilima Loomis

Ilima Loomis is a freelance journalist in Hawaii who covers science, travel and business.

Tagged With

Related Posts

Aquafeeds

Waste not: Novel protein-recapture initiatives for aquaculture

A Norwegian fermentation technology firm utilizes volcanic matter to transform salmon waste, including feces and uneaten feed, into a high-protein powder.

Responsibility

Integrated utilization of microalgae grown in aquaculture wastewater

A study shows that wastewater from recirculating aquaculture systems is suitable for microalgal cultivation and that sludge amendment to the wastewater increases production.

Health & Welfare

Culture of Pacific white shrimp juveniles in super-intensive conditions

Results of this study showed that L. vannamei juveniles can be cultured at high densities with adequate survival, growth and feeding efficiency, and with minimal water exchange or full water reuse through recirculation.

Aquafeeds

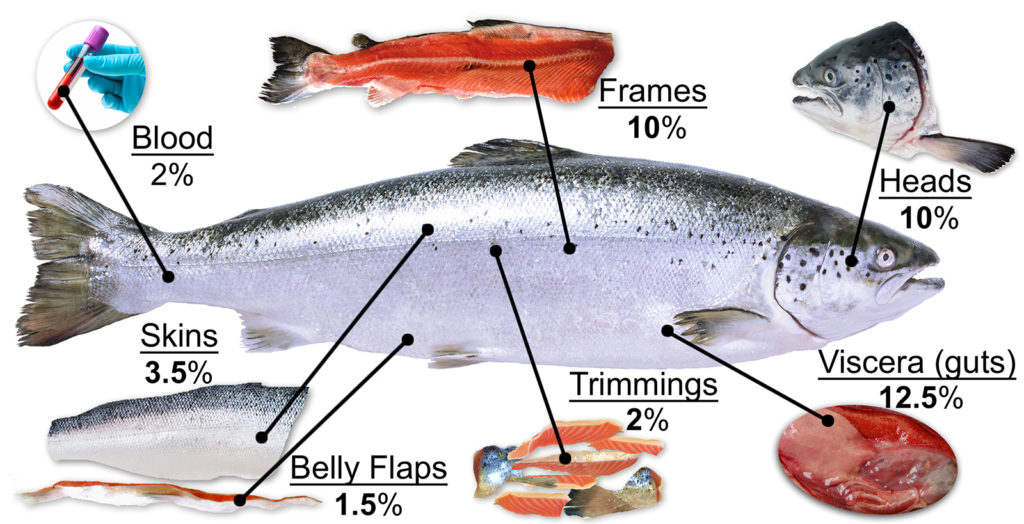

It takes guts to advance sustainability in aquaculture

With byproducts representing between 25 to 50 percent of the weight of various fish species, we need to be looking at how the entire fish is being used: even the heads, guts and skin.