Reservoir study: Fish sizes/prices must also be considered

Israel has suffered from a chronic water shortage for years. In recent years, however, the situation has developed into a severe crisis. The agricultural sector has been heavily challenged, but in spite of the obvious climatic constraints and overall shortage of water, both agriculture and aquaculture are highly developed in Israel.

A variety of methods are practiced to maximize water use and enable the production of fresh fish. First and foremost have been reservoirs to store rainwater during the wet season. Many of these are also used for fish culture in integrated farming systems. With support from the Ministry of Agriculture, fish farmers have invested around 100 million new shekels (U.S. $28 million) during the last three decades in developing this unique dual-purpose reservoir culture system and associated technology.

Water reservoirs

Traditionally, tilapia have been raised in ponds with differing structures, bottom types and depths. The main difference between an earthen pond and a reservoir is the depth of the water. Typical reservoirs in Israel, which have areas between 5 and 20 hectares, range between 4 and 15 meters in depth.

Originally, irrigation reservoirs were built to collect rain and flood waters in winter and brackish spring water for use in irrigating crops in summer. In order to catch larger amounts of rainwater during winter, the reservoirs were deepened.

The farmers of communal settlements decided to use the irrigation reservoirs for fish culture, in addition to their original purpose. In a few years, it became evident that rearing fish in such reservoirs was profitable, although professional and technological know-how was still lacking.

The introduction of tilapia to irrigation reservoirs improved the efficiency of water usage and reduced the cost of water needed for tilapia culture in conventional earthen ponds. However, the main problem was harvesting the fish, since the engineers who planned the reservoir construction did not take such activity into consideration.

Dramatic technological development has occurred since then, and many new dual-use reservoirs were constructed and equipped with a range of solutions for efficient harvesting. This has, in turn, changed the emphasis such that in the newly constructed reservoirs, tilapia culture became the primary activity and crop irrigation a byproduct.

Integrated reservoirs reduce the cost of water for fish farming, as some of the costs are recorded as irrigation expenses. These reservoirs are usually deeper than 5 meters to allow irrigation during the summer and ensure there is sufficient water until the end of the tilapia production season in the autumn. Heavy investments are necessary to install the equipment required for tilapia production and harvest in reservoirs.

Tilapia production

Due to the large volumes of the reservoirs, the fish output is much higher than for earthen ponds, reaching 10,000-20,000 kg/ha yearly. This quantity of fish is too large to be harvested from the pond pits at the end of the season. As a result, fish farmers usually harvest fish that have reached market size during the season to reduce the biomass. The reservoirs are equipped with harvesting equipment, such as lifting nets attached to motorized booms that are lifted with the catch.

The fish gather in a sleeve, which can be detached and dragged to the reservoir bank, where they are sorted and handled. Some reservoirs have concrete harvest pits at the ends of the outlet pipes by the drainage canals. The pits have strainers for separating the fish from the water, as well as life-support systems to ensure the welfare of the fish.

Technology improvements

The desire of fish farmers to recoup their investments in building reservoirs within five to seven years has led them to develop technologies that enable greater production per unit area. While in conventional earthen ponds, yields consist of 0.5-0.7 fish/L water, those achieved in reservoirs can approach threefold higher at 1-2 fish/L water. Various technical and biological factors contributed to this dramatic rise in yield.

High-density study

The author recently evaluated the economic feasibility of tilapia grow-out at high stocking density in irrigation reservoirs. The main question was whether the increase in fish yield resulted in higher profits. The data analyzed were collected from representative fish farms as well as economic reports.

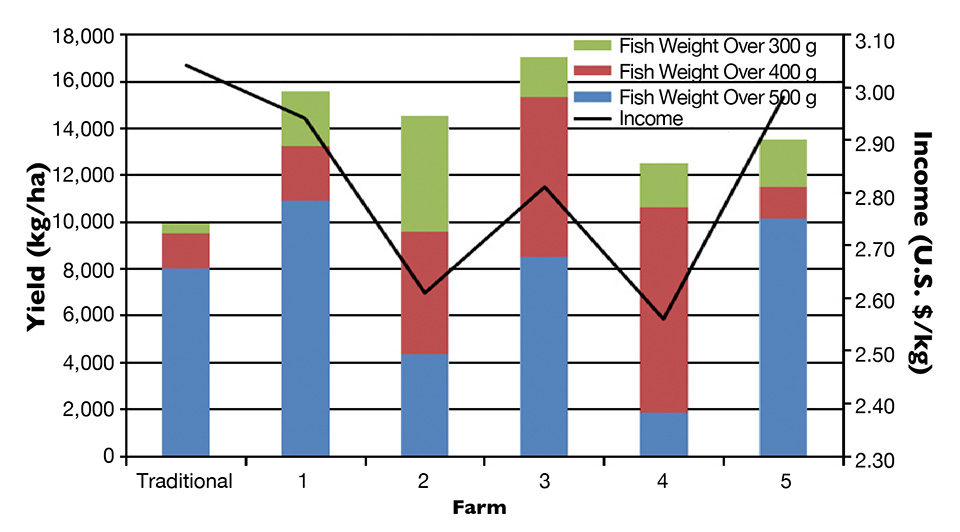

Current typical reservoirs yield about 1 metric tons (MT)/ha (1 kg per cubic meter) annually, while intensively managed reservoirs can yield higher volumes of fish. On average, fish weights at harvest are above 500 grams under typical management and 400 grams in the intensive reservoirs. Size distributions and incomes are presented in Fig. 1. Farmers receive average market prices of $3.19/kg for large tilapia over 500 grams in weight, $2.50/kg for 400- to 500-gram fish and $2.22/kg for 300- to 400-gram tilapia.

With increasing stocking density, farmers increase the number of paddlewheels for aeration by 25 to 35 percent, which results in higher energy costs. Variations among farms in production expenses for fingerlings, feed, energy and fixed costs not related to stocking density are due to differences in tilapia size at stocking, mortalities during grow-out, culture periods and management.

Results

Table 1 shows the results obtained in five fish farms practicing intensive culture compared to the average values for conventional culture of tilapia. The table presents average income and expenses for fingerlings, feed, energy and fixed costs – all calculated per 1 kg tilapia produced.

Simon, Profit analyses for traditional ponds, Table 1

| Traditional | Farm 1 | Farm 2 | Farm 3 | Farm 4 | Farm 5 | |

|---|---|---|---|---|---|---|

| Yield (kg/m3) | 1.00 | 1.50 | 1.35 | 1.70 | 1.25 | 1.30 |

| Fingerlings (U.S. $/kg) | 0.80 | 1.02 | 0.64 | 0.98 | 0.97 | 0.72 |

| Feed (U.S. $/kg) | 1.25 | 1.18 | 1.22 | 1.53 | 1.53 | 1.50 |

| Energy (U.S. $/kg) | 0.25 | 0.33 | 0.33 | 0.38 | 0.38 | 0.33 |

| Fixed costs (U.S. $/kg) | 0.64 | 0.70 | 0.61 | 0.68 | 0.73 | 0.65 |

| Total production cost (U.S. $/kg) | 2.94 | 3.23 | 2.80 | 3.57 | 3.61 | 3.20 |

| Income (U.S. $/kg) | 3.04 | 2.94 | 2.61 | 2.81 | 2.56 | 2.98 |

| Profit (U.S. $/kg) | 0.10 | -0.29 | -0.19 | -0.76 | -1.05 | -0.22 |

The bottom line was that the profits gained from tilapia production were higher in the traditional system than in the intensive culture management. Most farms lost money producing tilapia at higher production levels. Apparently, the other fish produced in the reservoirs (15 percent of the total yield) enabled them to not lose money altogether.

Perspectives

The Israeli aquaculture industry has developed a unique technology for growing out fish in water reservoirs that attracts people from all over the world. What impresses most visitors is the high yield produced per unit area, a common measure for annual returns on reservoir investment. However, profitability was never evaluated based on the size distribution of the harvested fish, since tilapia have a size-dependent market price.

The conclusion from the author’s study was that maximizing yield did not guarantee profitability. On the contrary, lower total yields consisting of larger tilapia under traditional management resulted in higher returns per kilogram of fish.

Thus, increasing tilapia yields in reservoirs above current levels by increasing stocking density would not be profitable at current price levels. Production gains should be achieved by increasing culture area and other inputs, including water, labor, energy, fingerlings and administration.

(Editor’s Note: This article was originally published in the January/February 2014 print edition of the Global Aquaculture Advocate.)

Author

-

Yitzhak Simon

Head of Aquaculture Division, Extension Service

Ministry of Agriculture and Rural Development

Agricultural Center

68 Hamadabeem Street

Rishon LeZion, Israel[108,105,46,118,111,103,46,103,97,111,109,46,109,97,104,97,104,115,64,110,111,109,105,115,105]

Tagged With

Related Posts

Health & Welfare

A look at tilapia aquaculture in Ghana

Aquaculture in Ghana has overcome its historic fits and starts and is helping to narrow the gap between domestic seafood production and consumption. Production is based on Nile tilapia.

Intelligence

Adding value to tilapia to tap into U.S. market

New markets for tilapia and expansion of existing ones can be created by planning and implementing properly designed geographic strategies to meet discriminating consumer preferences. Low labor costs in most producing countries promotes value-adding by the production of fresh fillets.

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.