Determining optimal stocking and harvesting strategies allows managers to maximize results

Nowadays in aquaculture production, managing the uncertainty of costs is more complicated than determining what they are. For a given set of production factors, why do we not always get the same results? The uncertainty over the outcome of the production process is called operational risk. During the farming process, the courses taken by events can result in different levels of production. The volatility of the results can be used as an indicator for measuring operational risk. So the difference between the best and the worst results shows the level of exposure to uncertainty.

Aquaculture factors

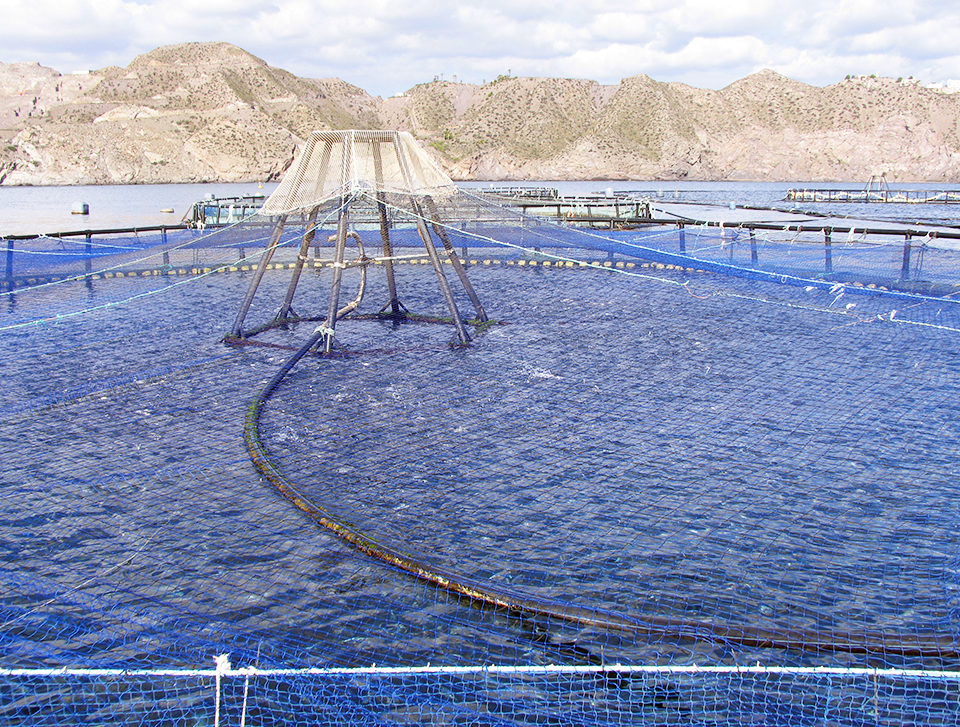

Offshore aquaculture production involves a large number of factors whose evolution cannot be controlled by companies, or their control is costly or not cost effective. Such factors include weather conditions, water parameters like salinity or oxygen levels, feed prices and diseases. However, there is another factor – management – that firms can influence to reduce their uncertainty.

Aquaculture management, particularly involving decisions about operational strategy, does not often receive the same attention management gets in other sectors. Yet aquaculture managers must regularly make decisions that affect efficiency, competitiveness and economic performance. Decisions on stocking and harvesting times, ration sizes, types of feed, or even the location of production facilities are under the responsibility of managers.

Potential risks

Uncertainty over the outcome of the production process is a risk that affects different areas of activity. When a strategy does not evolve as expected, the company may be unable to supply the agreed quantity of fish to its customers, or it may not have the money needed to meet the repayment of a loan. These imbalances have a high cost for the company in terms of both economics and reputation.

One way to reduce the level of uncertainty associated with decisions is to employ qualified managers who not only have biological and technical knowledge, but also economic and managerial skills. However, this is a partial solution, since human rationality does not guarantee optimal operational planning. To overcome this limitation when evaluating all possible production strategies in determining the one that maximizes economic performance, firms can apply different optimization tools.

Swarm intelligence

One method that can be applied to improve risk management in aquaculture is the application of “swarm intelligence,” which includes all the artificial intelligence techniques used to describe the collective behavior of decentralized systems and self-organized systems, natural or artificial.

The authors particularly use a “particle swarm optimization” (PSO) algorithm, a population-based optimization technique inspired by the social behavior of birds or fish.

A PSO algorithm based on a bioeconomic model can be implemented to help managers of aquaculture firms in the process of decision making. It determines the production strategy that maximizes the operational gross margin and minimizes operational risk.

The PSO algorithm developed for aquaculture helps users deal with two types of decisions. For operational decisions, the algorithm obtains the optimal solution under the conditions determined by the manager to plan the daily activity of a facility for a given period. For strategic decisions, the algorithm can be applied to obtain the optimal economic result in different scenarios under different conditions for the factors analyzed. Among others, the algorithm can assist in decisions on site selection, feed, production capacity or harvest weight.

Influence of location

As an example, the algorithm is applied to determine how environmental conditions affect the profitability and operational risk level for offshore aquaculture of gilthead sea bream in the two main production regions in Spain, the Canary Islands and the Mediterranean east coast. There are significant differences in water temperature between these locations. The production conditions considered a time horizon of five years, maximum biomass density of 20 kg/m3, 5 percent interest rate, maximum delay of 60 days between harvest and restocking, harvest weight of 300 to 700 g and weight range for fingerlings of 3 to 10 g.

The results in Table 1 show how the higher average water temperature in the Canary Islands would generate faster growth and higher returns. However, the operational risk in the Canary Islands is higher due to the greater number of potential operational strategies that increase uncertainty about the gross margin.

Llorente, Operational risks, Table 1

| Location | Best Operational Plan Units | Best Operational Plan Gross Margin | Worst Operational Plan Units | Worst Operational Plan Location | Operational Risk |

|---|---|---|---|---|---|

| Canary Islands | 5 | U.S. $255.75/m3 | 4 | U.S. $181.80/m3 | 40.66% |

| Eastern Spain | 4 | U.S. $185.69/m3 | 4 | U.S. $160.43/m3 | 15.76% |

If a manager chose a production strategy based on knowledge and experience, the economic result would likely fall between the worst and best strategies obtained by the algorithm. However, if a manager uses this type of approach, the result will be the production strategy that allows achieving the maximum economic return given the conditions of production. This removes the risk arising from the uncertainty associated with manager’s decisions.

Perspectives

Aquaculture production management is an activity that depends on human knowledge and rationality. Determining optimal stocking and harvesting strategies allows managers to maximize results and eliminate operational risks. Artificial intelligence techniques such as PSO are a tool to optimize the results, minimize the costs and eliminate the uncertainty of aquaculture enterprises. These new methodologies open a future line of work in operational risk analysis in aquaculture.

The development of tools like a decision support system would allow managers to make decisions considering multiple aspects that affect the growing process, even if they do not have an expert knowledge of the same. Additionally, such systems would support the fast and efficient processing of large volumes of data. Greater capacity to address changes in the environment allows aquaculture companies to be more competitive and adapt to the rapid changes in markets.

(Editor’s Note: This article was originally published in the September/October 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

Prof. Ignacio Llorente, Ph.D.

Universidad de Cantabria

Avenida de los Castros s/n 39005

Santander, Cantabria, Spain[115,101,46,110,97,99,105,110,117,64,105,101,116,110,101,114,111,108,108]

-

Prof. Ladislao Luna, Ph.D.

Universidad de Cantabria

Avenida de los Castros s/n 39005

Santander, Cantabria, Spain -

Prof. José Fernández-Polanco, Ph.D.

Universidad de Cantabria

Avenida de los Castros s/n 39005

Santander, Cantabria, Spain -

María D. Odriozola

Ph.D. Candidate

Universidad de Cantabria

Avenida de los Castros s/n 39005

Santander, Cantabria, Spain

Tagged With

Related Posts

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Intelligence

Aquaculture key to increasing seafood supplies to Arab states

Arab States have substantial natural resources to increase aquaculture production. Several types of systems are readily adaptable and can be implemented relatively quickly.