Avoid unit processes, excess piping and other components that are difficult to clean and disinfect

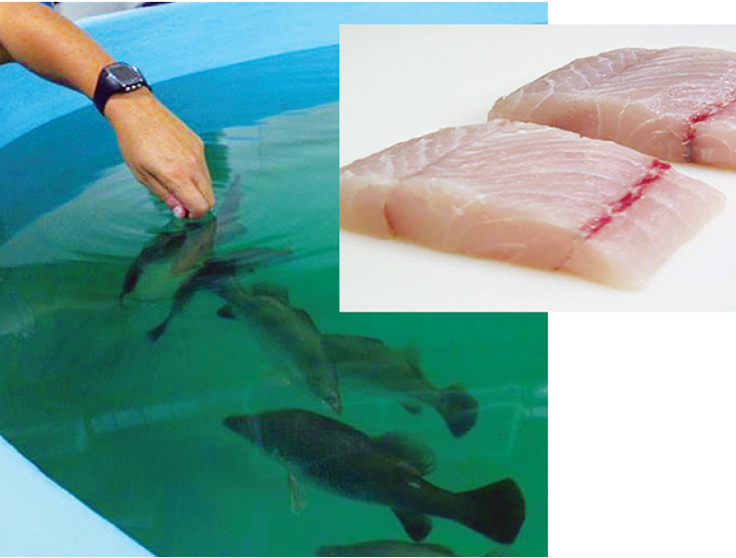

Fish cultured within recirculating aquaculture systems (RAS) can bioaccumulate the off-flavor compounds geosmin and 2-methylisoborneol (MIB) in their flesh. These off-flavor compounds are produced by actinomycete bacteria associated with biosolids and biofilms that form on tank walls and the submerged surfaces of unit processes.

These off-flavors are often described as “earthy” or “musty” by consumers, and if present at high enough concentrations can result in product that is unpalatable and unacceptable for the marketplace. Therefore, it is critical for RAS facilities to establish effective standard operating procedures that consistently mitigate off-flavor and result in good-tasting end products.

Removing off-flavor

The standard practice used to remove off-flavor from RAS-produced food fish prior to slaughter is known as depuration or purging. Ideally, fish are relocated to separate systems operated with some water flushing, such as flow-through or partial-reuse systems with no biofilter. While fish are held in depuration systems, they are kept off feed for a period depending upon a variety of factors, such as fish species and size, temperature and water quality of the purge system and supply water, and intensity of the off-flavor in the fish flesh.

When concentrations of geosmin and MIB are maintained at sufficiently low levels within depuration systems, off-flavor compounds gradually diffuse out of fish flesh, thereby resulting in “on-flavor” fillets. At The Conservation Fund’s Freshwater Institute research facility, rainbow trout and Atlantic salmon are effectively purged for six days while held in clean partial-reuse systems flushed with odor-free, 12-14 degrees C spring water.

Although depuration is arguably one of the most important steps for RAS food fish production, very little research has been devoted to optimizing standard operating procedures to mitigate off-flavors. Therefore, the authors recently conducted a study to evaluate operating practices and system design parameters that could potentially enhance depuration of off-flavors from Atlantic salmon cultured to harvest size of about 4 kg within a semi-commercial-scale freshwater RAS.

Key design parameters

The key system design parameter evaluated during the trial was the presence or absence of water aeration media within the gas transfer columns of each depuration system. This focus was based on anecdotal evidence that ineffective purging can occur in partial-reuse systems that contain biofilm-coated water aeration media. The high-surface-area media was suspected to harbor actinomycete bacteria and biofilms associated with off-flavor production, which could explain inadequate purging experiences.

Water aeration media is often used within RAS and partial-reuse systems to evenly distribute water to facilitate gas exchange such as carbon dioxide removal or oxygen addition during aeration. Such media is purposely designed with high specific surface area.

However, the increased surface area also provides significant substrate for the attachment and growth of bacterial biofilms. In addition, it creates a challenge for effective disinfection, because water tends to channel around layered media, thereby inhibiting complete contact of recirculated disinfectants with all surfaces.

With this in mind, the second variable evaluated during the study was the use of hydrogen peroxide to disinfect depuration systems prior to stocking fish. It was hypothesized that salmon depurated in systems disinfected with hydrogen peroxide and void of water aeration media would purge more effectively in comparison to alternative treatments.

Depuration study

The depuration study was conducted using 12 partial-reuse systems of 0.5-cubic-meter volume, each operated with a recycle rate of 95 percent on a flow basis. The systems were relatively simple in design, consisting of a circular single-drain tank, a water aeration column and a magnetic drive pump that recirculated the water. Four combinations of the two key treatments were evaluated by using three replicate systems per treatment.

It is important to point out that rainbow trout were intentionally cultured in the experimental depuration systems prior to the study to create biofilm-coated surfaces and a potential “worst case scenario” to purge off-flavors. One day prior to the study, the trout were removed, and the tanks were thoroughly brushed. However, the water aeration columns and media within them were not brushed or cleaned.

Six partial-reuse systems were disinfected with 250 mg/L hydrogen peroxide for one hour with no dilution. The peroxide was then flushed from these systems. The next day, 14 Atlantic salmon weighing 3 to 5 kg each were stocked into each experimental depuration system.

Six fish were removed directly from the semi-commercial-scale RAS and filleted to obtain samples for baseline assessment of off-flavor. On days 3, 6 and 10, three to four fish were removed from each depuration system to evaluate off-flavor mitigation kinetics. Fillet samples were vacuum sealed, frozen and shipped to the Lacombe Research Centre in Alberta, Canada, for analysis of MIB and geosmin concentrations.

Results

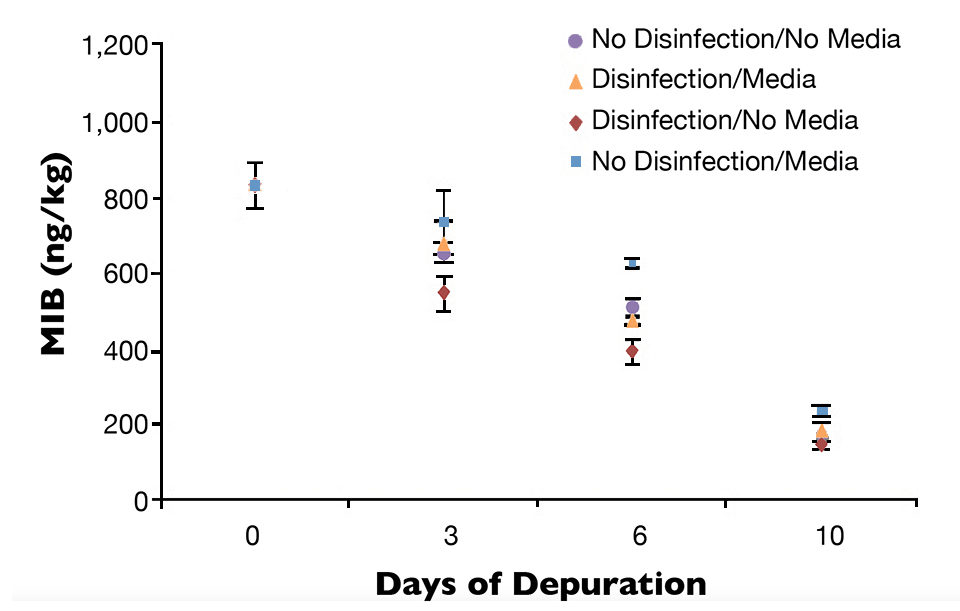

The results of the study matched the hypothesis that salmon depurated in disinfected systems void of water aeration media purged more effectively than fish depurated using alternative treatments. Fig. 1 illustrates that Atlantic salmon held in disinfected systems without the media depurated faster and had lower MIB concentrations throughout the depuration period compared to other treatment combinations. Conversely, salmon depurated in systems that were not disinfected and contained water aeration media released off-flavor at a slower rate and contained the highest concentrations of MIB.

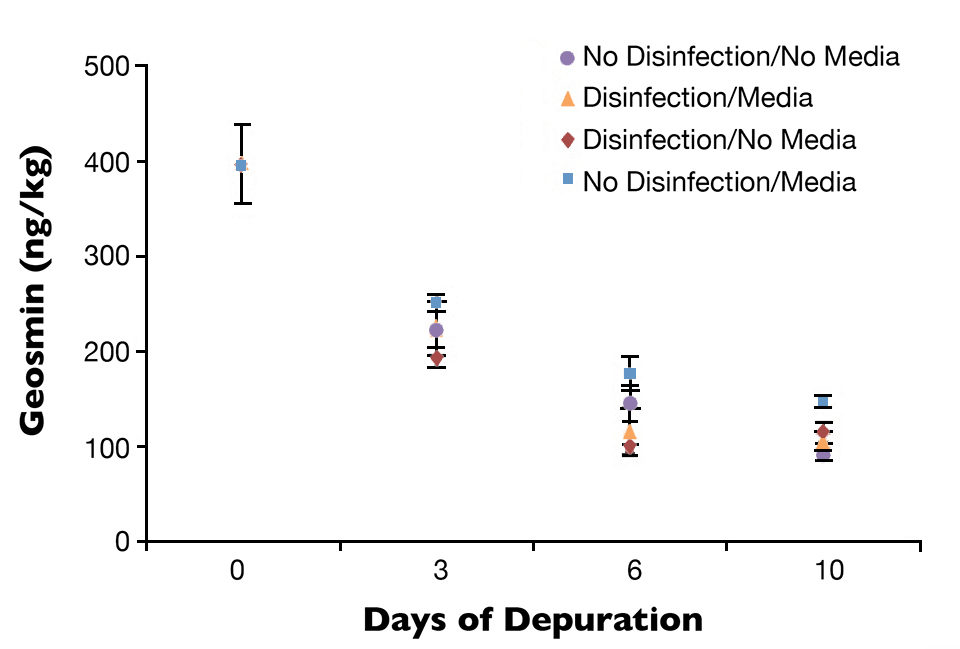

Similar results occurred relative to the depuration of geosmin (Fig. 2). From days 0 to 6, salmon held in pre-disinfected systems and void of water aeration media depurated faster and had lower geosmin concentrations compared to other treatment combinations.

Conversely, salmon depurated in systems that were not disinfected and contained aeration media released geosmin at a slower rate and contained the highest geosmin concentrations within fillets. There was no significant difference in geosmin between days 6 and 10 for this treatment, indicating reduction of geosmin might have reached a low threshold.

Another key finding from the study was that off-flavor concentrations within individual Atlantic salmon varied widely. For example, the range of MIB concentration for salmon purged within disinfected systems void of media was 74 to 226 ng/kg. Interestingly, salmon depurated in these systems had the tightest range of off-flavor concentrations, while salmon depurated using other treatments had wider-ranging concentrations.

Off-flavor detection

The goal of depuration should be that all fish have undetectable off-flavor concentrations prior to final harvest. Based on the range of off-flavor compound concentrations measured during this study, tasting only one fish is likely not a representative method to determine market suitability. RAS producers might consider filleting three to five fish and conducting an on-site flavor evaluation with trained panelists before the product is considered on-flavor and ready for market.

It is important to point out that the geosmin and MIB concentrations measured during this trial were possibly below the average human sensory detection thresholds for Atlantic salmon, which have been preliminarily reported in literature as greater than 900 ng/kg for MIB and 400-500 ng/kg for geosmin. More research is needed to specifically define these detection thresholds.

Perspectives

The findings from the study indicated that water aeration media with high specific surface area should not be used within depuration systems unless it is removed between each lot of fish and thoroughly washed, cleaned and disinfected. The absence of the media within depuration systems should not present a problem relative to carbon dioxide removal, because the aeration columns still function without packing, though at a lower gas-transfer rate. However, this is mostly offset in depuration systems, because fish produce less carbon dioxide and use less oxygen when they are kept off feed.

Carbon dioxide and dissolved-oxygen concentrations were not substantially different in systems with and without water aeration media. Based on the study results, it is also reasonable to conclude that depuration systems should be as simple in design as possible and avoid unit processes, excess piping and other components that are difficult to clean and disinfect.

Editor’s Note: More details on this study can be found in a recently published paper in the July 2014 Aquacultural Engineering.

(Editor’s Note: This article was originally published in the September/October 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

John Davidson, M.S.

The Conservation Fund’s Freshwater Institute

1098 Turner Road

Shepherdstown, West Virginia 25443 USA[103,114,111,46,101,116,117,116,105,116,115,110,105,114,101,116,97,119,104,115,101,114,102,64,110,111,115,100,105,118,97,100,46,106]

-

Kevin Schrader, Ph.D.

United States Department of Agriculture

Agricultural Research Service -

Christopher Good, Ph.D.

The Conservation Fund’s Freshwater Institute

1098 Turner Road

Shepherdstown, West Virginia 25443 USA -

Steven Summerfelt, Ph.D.

The Conservation Fund’s Freshwater Institute

1098 Turner Road

Shepherdstown, West Virginia 25443 USA

Tagged With

Related Posts

Innovation & Investment

AquaBounty, with new RAS facility, hopes to win public support for GM salmon

Ron Stotish, CEO of AquaBounty Technologies, believes genetically modified salmon is no threat to its opponents and the outlook for AquAdvantage is good. With its purchase of the Bell Fish Co. RAS facility, commercialization will soon commence.

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.

Intelligence

Adding flavor complexity to farmed barramundi

Organoleptic attributes such as flavor and aroma are among the most important factors that influence consumer acceptability and demand for fish products. Consumers have identified farmed fish as less complex and lacking “sealike” or “sea-fresh” flavors and aromas.

Health & Welfare

Novel air-based system transfers large salmon during harvest

To evaluate the application of an air pressure-based transport method within a recirculating aquaculture system, the authors performed testing with harvest-size salmon at The Conservation Fund Freshwater Institute.