Solution for maintaining D.O. at higher stocking densities

Maintaining optimum dissolved-oxygen (D.O.) levels, particularly toward the end of a season, is an issue that is especially critical at intensive and super-intensive shrimp farms. One approach to D.O. maintenance that is gaining traction in the industry focuses on injecting high-purity oxygen – rather than air – into ponds. This new approach not only helps farms quickly recover from low D.O., but can also prevent ponds from facing that dilemma in the first place.

Oxygen injection applications

The main components of oxygen injection systems are an oxygen source (tanks or oxygen generator), a hose or other tubing to transfer the oxygen, and a diffusion device, which can vary from a simple airstone to powered mechanical injectors. A source of power is also usually required.

New technology for oxygen generation at pond side using vacuum swing absorption and high-efficiency injection reduce the cost and improving the reliability of pure oxygen systems. Intensive pond facilities can now consider oxygen injection as a practical option in an overall strategy for D.O. management.

Following are some examples of farms where oxygen injection systems were successfully used to raise decreasing pond D.O.

Saving a pond

One late afternoon, the manager of a shrimp farm in the United States was performing his routine inspection when he noticed shrimp floating along the side of a pond. He also saw black spots on a number of shrimp tails. To his experienced eyes, it was a clear indication of high nitrite levels in the pond water. As it turned out, the D.O. in the pond measured about 2.8 ppm and was falling rapidly.

As with nearly every other farm, this caused concern and an immediate call to action. An initial decision was made by the farm team to add molasses for the nitrites and exchange water to address the low D.O. But due to the size of the pond and the drains, emergency water exchange would have made little immediate impact.

Two weeks prior, the farm had planned trials using a system to inject high-purity oxygen into its ponds. Because of the current situation, the farm manager decided to immediately deploy the oxygen system to address the low D.O. The system was up and running within an hour, working to address a D.O. level that had dropped to 2.1 ppm and was continuing on a downward trend. The D.O. stabilized and by midnight started to rise. By early morning, the D.O. had risen to 5 ppm and the pond was saved. The farm may have lost this pond using conventional approaches.

Maintaining D.O. levels

In a similar occurrence, a 1.5-ha, high-intensity pond at a farm in Latin America was approaching harvest. Early one afternoon, farmers realized that the pond’s D.O. never rose above the morning low of 3 ppm, and it was likely the already-low D.O. would further decrease overnight. Fortunately, this farm also had a new oxygen injection system installed for a trial.

The system was deployed, and in the next three hours the D.O. reached 7 ppm – stabilizing the pond.

Increasing production

Not all situations involving low D.O. have such a sense of urgency. A juvenile and grow-out raceway farm in the U.S. had been using air blowers with stones for aeration in the raceways. The conversion to a high-purity oxygen system allowed it to consistently maintain D.O. levels above 5 ppm, enabling the farm to double the grow-out stocking density and still achieve 20 percent higher growth rates.

D.O. variations

These stories demonstrate how today’s shrimp farms can overcome the challenges of low D.O. by injecting high-purity oxygen into ponds instead of generating oxygen from conventional aeration techniques. But that’s not the complete story.

As farmers look to higher stocking densities, they are challenged with preserving survival and growth targets. Oxygen injection offers a solution for maintaining D.O. at higher stocking densities.

As farmers know, pond D.O. levels fluctuate diurnally in open-air farms. D.O. levels traditionally peak in the late afternoon due to the influence of algae – which grow in the presence of sunlight and feed on nutrients within pond water – but drop dangerously overnight. High-density systems, for example, can witness D.O. levels that drop as low as 1 ppm in the morning, despite traditional aeration techniques.

Other frequent and frustrating issues faced by intensive and super-intensive shrimp growers include power failures, aerator breakdowns, and sudden algae crashes. It may take several hours to rectify any of these problems – critical time during which pond managers struggle to sustain the lives of the animals in their ponds without the ponds experiencing decreased D.O. levels. Again, oxygen injection may hold the key.

Emergency aeration alternatives

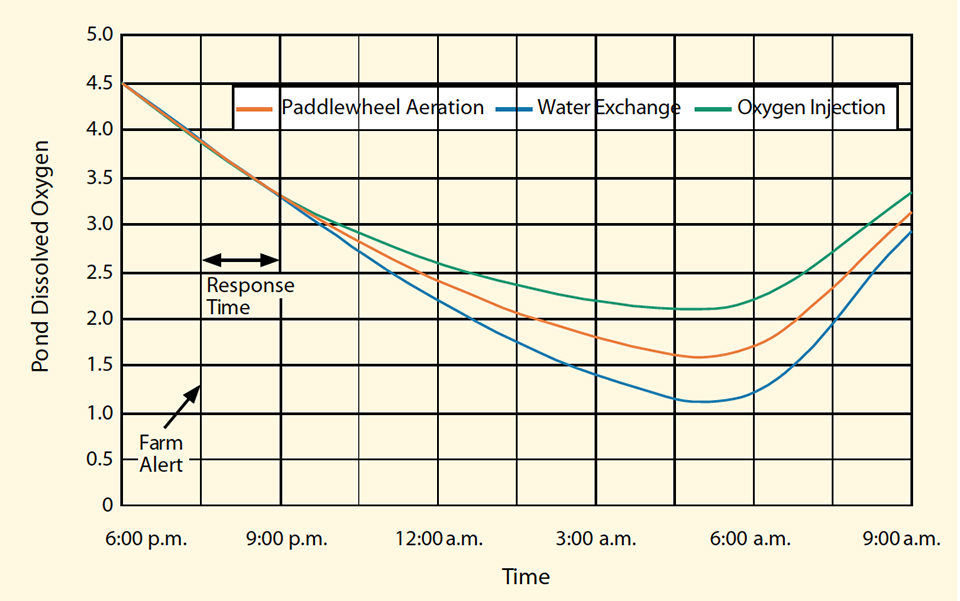

Today, the two most widely practiced emergency techniques for dealing with low D.O. are water exchange and supplemental paddlewheel aeration. Both are somewhat effective in reducing the impact of low D.O., but have limitations. Emergency water exchange takes valuable time and in the process can cause sudden animal stress, unstable water chemistry, and an increased risk of newly introduced diseases. Emergency paddlewheels and tractor-driven paddlewheels require time, significant logistical coordination, and manpower to deploy.

What technique to use is an important decision. Semi-intensive and intensive farms typically harvest 5 to 20 metric tons (MT) per hectare of shrimp with a value of $30,000 to 120,000 per season using 12 to 60 hp of aeration. Despite this high level of aeration, ponds can still experience low D.O. If not addressed promptly, harvests are affected and possibly lost … along with the profits.

Neither paddlewheels nor water exchange is as effective in raising D.O. as injecting oxygen. That’s because the ultimate oxygen saturation level with air is less that 25 percent that of high-purity oxygen.

Oxygen injection

There are a number of important considerations for those interested in exploring the concept of oxygen injection.

Oxygen supply. Oxygen can be supplied from high-pressure gas cy-linders, liquid oxygen storage tanks, or oxygen generators. Due to the remote location of shrimp farms, oxygen generators are usually the lowest-cost method of supply. The oxygen generators should be designed to operate in the hot, humid, and corrosive conditions at a shrimp farm.

Efficient injection. For the lowest operating cost, the equipment used to inject oxygen into ponds must be capable of injecting and dissolving the oxygen in an energy-efficient manner. A dissolution efficiency of greater than 80 percent is a good target.

Uniform oxygen distribution. Oxygen injection systems should include a mixing mechanism to distribute oxygen-rich water throughout the pond. If oxygen injection is used to supplement paddlewheels, the paddlewheels provide some mixing effect. A well-designed oxygen injection system can further enhance distribution.

Ease of start-up and deployment. When pond D.O. levels drop, time is very important, and the quicker the oxygen is supplied, the greater the benefit. Ideally, a simple, portable system should be designed to minimize the time needed to get the system to ponds, connected to power, and in operation.

Simplicity and reliability. The equipment should be simple enough for farm workers to operate and rugged enough to easily move it around the farm.

Oxygen intensification

Oxygen injection systems are essentially “oxygen intensification systems” capable of rapidly providing the optimum amount of oxygen and aeration needed during each period of the grow-out season.

Oxygen injection technology is also being employed through integrated systems that cover entire farms. In these applications, the technology can help manage the demand for oxygen, particularly in the latter stages of grow-out, when sludge generates a large demand. Well-designed systems can also improve sludge collection by helping to optimally move added water.

(Editor’s Note: This article was originally published in the June 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Ashok Mathur

Product Manager

Air Products

7201 Hamilton Boulevard

Allentown, Pennsylvania 18195 USA[109,111,99,46,115,116,99,117,100,111,114,112,114,105,97,64,110,97,114,117,104,116,97,109]

-

Dr. Anantapur Rafiuddin

Chief Aquaculturist

Paradise Shrimp Farm

Edisto Island, South Carolina, USA

Tagged With

Related Posts

Responsibility

Airlifts combine pumping, water treatment in recirculation systems

Using the buoyancy of the entrained air bubbles to lift the water, airlifts are more energy-efficient and provide more aeration, carbon dioxide removal and foam fractionation for dissolved solids removal than centrifugal pump systems.

Responsibility

Speece cones saturate water with oxygen, ozone

Speece cones are capable of providing high concentrations of dissolved oxygen or ozone for water used in aquatic systems. High pressure within the cone systems diffuses the oxygen or ozone into the water as it flows downward through the inverted cone shape of the units.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Health & Welfare

Novel air-based system transfers large salmon during harvest

To evaluate the application of an air pressure-based transport method within a recirculating aquaculture system, the authors performed testing with harvest-size salmon at The Conservation Fund Freshwater Institute.