Maintaining favorable gut microflora can help minimize disease impacts

The strong fluctuations of feed ingredient prices in combination with low market prices for shrimp are challenging the profitability of shrimp farming. This has accelerated a search for alternative formulations and feed additives to improve the cost efficiency of feeding under various scenarios of ingredient cost and availability.

Whereas most of the optimizations target resolving nutritional bottlenecks in the formula, maintaining a stable and favorable gut microflora is potentially important to minimize the impact, of disease events and maximize digestive efficiency in shrimp.

Microflora exchange

Shrimp actively “graze” on the bottom substrate and therefore are highly exposed to exchanges of microflora between the environment and the digestive system. This increases the risk for the proliferation of an unfavorable gut microflora or frequent destabilization of the microflora, which can affect the optimal functioning of the digestive system. Furthermore, the digestive system of shrimp is the main entry port for bacterial and viral infections, which remain a major risk for the profitability of shrimp production.

Sustainable approaches to modulate the gut microflora in farmed animals include the use of selected bacteria to inoculate the gut (probiotics), specific nutrients that promote the development of selected bacterial strains (prebiotics) and specific natural compounds (mostly derived from yeast and herbal extracts, called “phytobiotics”) capable of modulating the microflora toward a composition that favors the development of beneficial bacteria and inhibits potentially pathogenic microorganisms. The latter strategies have the advantage of being easily applicable at the feed mill on large volumes of feed and avoiding major adaptations of production protocols at farms.

Study setup

To examine the potential of phytobiotic feed additives as a new area for improving the cost efficiency of shrimp farming under semi-intensive conditions, the authors performed a study. A synergistic blend of botanical extracts was selected for their bacteriostatic and bactericidal properties against pathogenic and potentially pathogenic bacteria in vitro using the disk diffusion method.

In previous work led by author Dr. Peter Coutteau, the phytobiotic blend promoted growth in healthy shrimp under controlled lab conditions. The shrimp showed a 20 percent increase in weekly weight gain and 4 percent improvement in food conversion. The efficacy of the botanical blend was then tested under field conditions for shrimp production in Panama during the dry season of September 2009 to February.

Test conditions, protocol

The dry season in Panama is characterized by unstable climatological conditions that result in strong temperature fluctuations, which in turn affect shrimp growth and the incidence of white spot syndrome virus. During the trial, the farm’s standard feed was used for both treatments, with the only difference between feeds being the supplementation of a phytobiotic growth promoter (Sanacore® GM). The growth promoter was added during feed processing at the feed mill at a dosage of 3 kg per metric ton (kg/MT) of feed during the first month after stocking and at 2.5 kg/MT during the rest of the culture period.

The trial was carried out in eight replicate 3-hectare ponds per treatment at the Camaronera de Cocle S.A. (CAMACO) Farm in Panama. The average duration of the culture period was 141 days for both treatments. Shrimp used in the trial were obtained from the Larval Production Centre of CAMACO at San Carlos, Panama. They arrived at the farm as PL10s and were acclimated in a raceway before being stocked in PL25 stage at 8 per square meter.

Pond management followed the routine production protocols of the farm, including pond drying one month after the last harvest and filling with filtered water using 285-µ nets. Shrimp were fed twice a day from a boat using feeding trays. Initially, 2-mm feed pellets were used during the first three weeks, followed by 2.2-mm pellets until harvest. Water exchange was zero during the first month and 5 to 7 percent daily based on water quality requirements.

Feed adjustments were made based on weekly growth estimates. Survival and shrimp size were estimated weekly using cast nets. Final production data at harvest obtained from the processing plant were based on head-on, packed product.

Production results

The supplementation of the phytobiotic feed additive resulted in improved values for all production parameters analysed in the study (Table 1). Survival and processed crop yield presented highly significant (P < 0.03) improvements, amounting to relative increases of 24 and 35 percent over the control group, respectively.

Vaca, Production results after processing for control shrimp, Table 1

| Treatment | Survival | Shrimp Size (g) | Crop Yield (kg/ha) | Feed (kg/pond) | Feed-Conversion Ratio | Weekly Growth (g) | Average Coefficient of Variation (%) |

|---|---|---|---|---|---|---|---|

| Phytobiotic | 55.5 ± 7.1a | 16.6 ± 1.5a | 735 ± 78a | 4,170 ± 338a | 1.91 ± 0.23a | 0.825 ± 0.075a | 10 |

| Control | 44.6 ± 10.6b | 15.7 ± 2.9a | 543 ± 90b | 3,464 ± 396b | 2.17 ± 0.39a | 0.776 ± 0.137a | 18 |

| Change | +24.4% | +5.8% | +35.2% | +20.4% | -12.1% | +6.3% | -41% |

| P Value | 0.0304 | 0.4395 | 0.0004 | 0.0018 | 0.7130 | 0.3876 | – |

Although the other parameters did not show significant differences between treatments, important improvements were observed for the treatment that received the phytobiotic, including 5.8 percent larger average shrimp size at harvest and 12 percent better feed conversion compared to the control group. The addition of the botanical product also greatly reduced the coefficient of variation of production results among ponds fed the same feed.

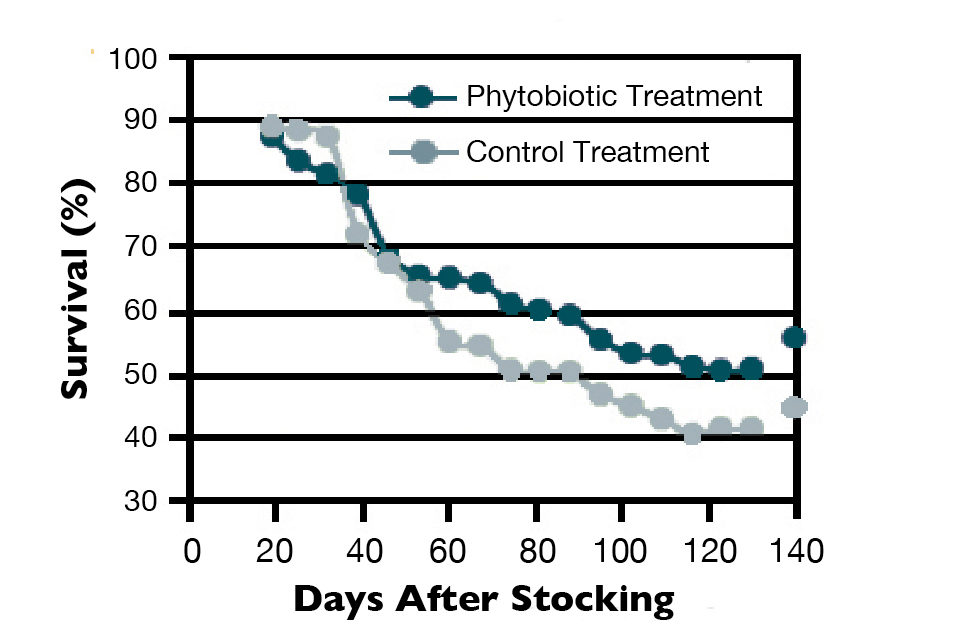

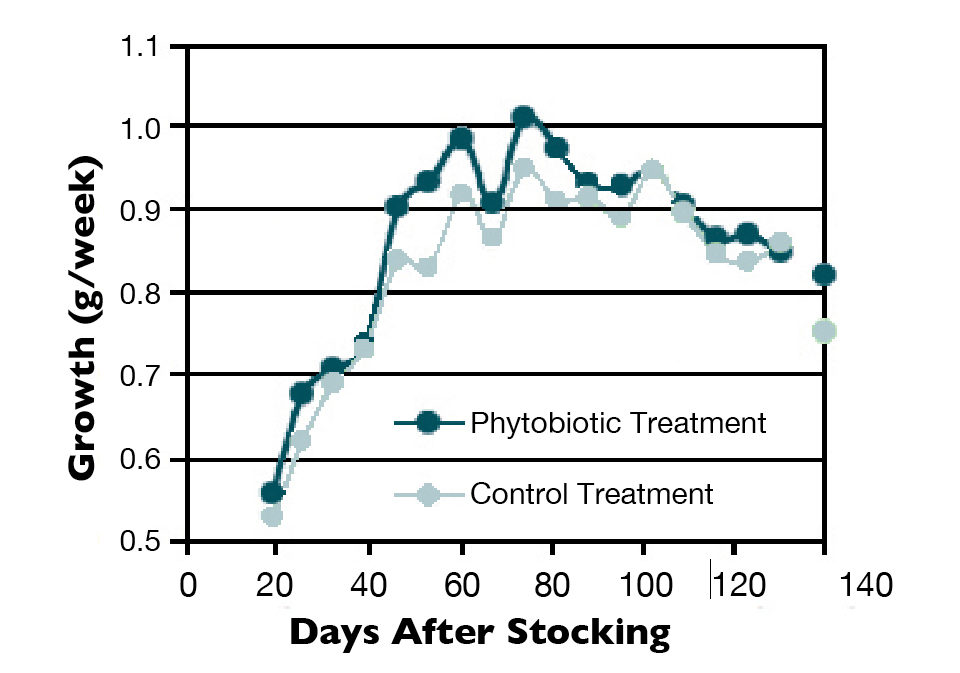

Sampling using cast nets indicated the incidence of major mortalities during the first two months after stocking. The phytobiotic treatment maintained an advantage on survival rate compared to the control group of approximately 10 percent from that point until final harvest (Fig. 1). Weekly estimates of average shrimp size showed periods of superior weekly weight gain throughout the production cycle for shrimp fed the phytobiotic product, with major differences observed between 50 and 100 days after stocking (Fig. 2).

The positive effects of the phytobiotic product on survival may be related to the fact that this study was performed during the worst farming cycle of the year in Panama, when shrimp ponds are exposed to severe transitional changes in weather at the end of the wet season and the beginning of the dry season.

White spot syndrome outbreaks with similar frequency and severity were confirmed in both treatments. The presence of a synergistic blend of phytobiotics with antimicrobial activity possibly protected the shrimp from coinfections with opportunistic bacteria, often the major cause of mortality in shrimp infected with white spot syndrome virus.

Higher crop yield per hectare due to better survival often results in slower growth due to the reduced availability of natural food. Despite significantly higher survival and crop yield due to the phytobiotic supplementation, positive effects on growth rate and food conversion were observed. This confirmed that the continuous dosing of natural antimicrobial activity in the feed results in beneficial physiological effects from stabilizing the microflora present in the culture animals’ digestive systems.

Economic analysis showed that under the local conditions of production and feed ingredient costs, the feed cost per kg of shrimp produced was reduced 10.9 percent due to the application of the phytobiotic additive.

(Editor’s Note: This article was originally published in the November/December 2010 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Alí Vaca

Camaronera de Cocle S.A.

Aguadulce, Panama -

Jorge Cuéllar-Anjel, DVM

Camaronera de Cocle S.A.

Aguadulce, Panama -

Roberto Chamorro

Camaronera de Cocle S.A.

Aguadulce, Panama -

Susset Dager

Alimentos Larro

Industrias de Nata S.A.

Grupo Calesa

Aguadulce, Panama -

Peter Coutteau, Ph.D.

Nutriad International N.V.

Kloosterstraaat 1 Bus 7

Kasterlee, Belgium[116,101,110,46,100,97,105,114,116,117,110,64,117,97,101,116,116,117,111,99,46,112]

Tagged With

Related Posts

Health & Welfare

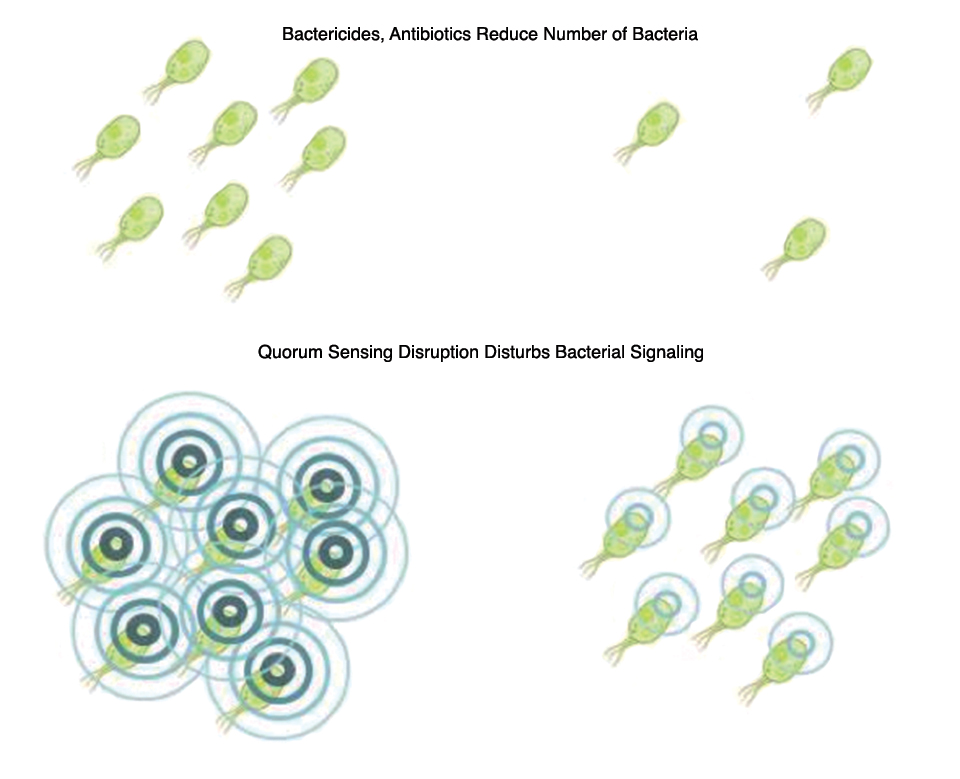

Feed additives based on quorum sensing disruption could aid fight against EMS

The pathogenicity of early mortality syndrome in shrimp is likely regulated by quorum sensing, which allows the Vibrio bacteria that colonize shrimp guts to coordinate the release of the toxin that damages shrimp digestive systems.

Health & Welfare

Focus on gut health increases aquaculture productivity

Increased attention to nutrient digestibility and gut health are two important focus areas for technological development of manufactured feeds in the aquaculture industry. Both laboratory and field studies have demonstrated the potential benefits for aquaculture productivity and the economics of specific feed additives developed to stimulate the establishment of a healthy gut microflora.

Aquafeeds

Natural feed additive improves shrimp productivity

The digestive systems of shrimp are main entry points for bacterial and viral pathogens, and unfavorable microflora. Natural feed additives that combine different actions have proven effective in improving survival where shrimp are exposed to bacterial pathogens.

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.