A pivotal role in future development of organic aquaculture

Various chemical agents are used to improve water quality in aquaculture. An important part of system management, water quality control includes measures to reduce bacterial loads and control fungal and ectoparasitic infestations in fresh- and saltwater systems.

Some systems rely on continuous disinfection with ultraviolet rays or ozone, whereas others rely on periodic flushes or baths using biocides. Peracetic acid (PAA) is an example of the latter, having strong oxidizing potential and antimicrobial abilities similar to those of ozone. PAA products are emerging in numbers and modes of application, and their aquaculture-related use has increased significantly over the last few years.

Peracetic acid

PAA is only available in acidified, stabilized solutions with hydrogen peroxide and acetic acid. The compositions and strengths of the products vary, with active concentrations of PAA typically ranging 5-15 percent/L.

This relatively broad concentration range is the first thing to consider when planning water treatment. PAA products are used in most of the rearing phases, for egg disinfection and water quality control in hatcheries, raceways, growout tanks and delivery ponds. PAA can efficiently control parasites, reduce dinoflagellates and suppress fungal infections related to the handling of broodstock.

Treatment efficacy

PAA has proven effective in controlling the parasites Ichthyophtirius multifiliis (ICH), which causes white spot disease, and Ichthyobodo necator-costia in fish, and the mold Saprolegnia on eggs.

Prophylactic treatment of eggs is done by mixing PAA with water and adding this solution to the inlets of egg trays. Treatment concentrations applied to juveniles, fingerlings and grow-out sized fish are relatively low, in the range of 2-10 mL/m3, depending on water quality and the PAA product used. This corresponds to PAA concentrations on the order of 0.3-1.5 mg/L.

Due to the highly reactive properties of PAA, residual concentrations rapidly decline – especially in water rich in organic matter. This is an issue to take into account when using PAA. If a system contains large pools of organic matter, higher PAA dosages are needed.

Using a low-dose PAA in organic-rich water can result in degradation of the chemicals within a few minutes, which has implications for the locations of PAA applications. If added at the inlet to a long raceway, for example, the chemical may degrade before it reaches the end of the raceway. In such cases, the use of multiple sites of application or repetitive dosing is recommended.

System design addressing tank configuration, flow and the presence of biofilters must also be taken into account.

PAA application

Choosing the correct dose of PAA depends on the water composition, fish size, temperature and system design. Treatment protocols include pulse dosage, where the chemical is added once on a daily basis. They can also include repetitive additions or continuous low dosage over prolonged periods.

In systems with low organic matter content – hatchery facilities and well water ponds, for example – continuous PAA application can be a feasible solution to control water quality. Continuous addition relies on dosage pumps and adjustment of dose according to flow and makeup water. Recent experiences at some Danish fish farms that apply prolonged, continuous daytime addition of PAA showed that the usual outbreaks of white spot disease were avoided.

Environmental impacts

Due to the low doses applied and rapid degradation of PAA, residual amounts of the chemical appear at very low levels, if present at all, in effluents. With half-lives on the order of a few minutes, PAA products degrade within ponds, raceways or constructed wetland, leaving no residues to enter receiving water bodies.

The degradation product of PAA is acetate. Harmful disinfection by-products are not formed when using PAA, making it a benign disinfectant when compared to chloramine-T, sodium chloride, formaldehyde and copper sulphate.

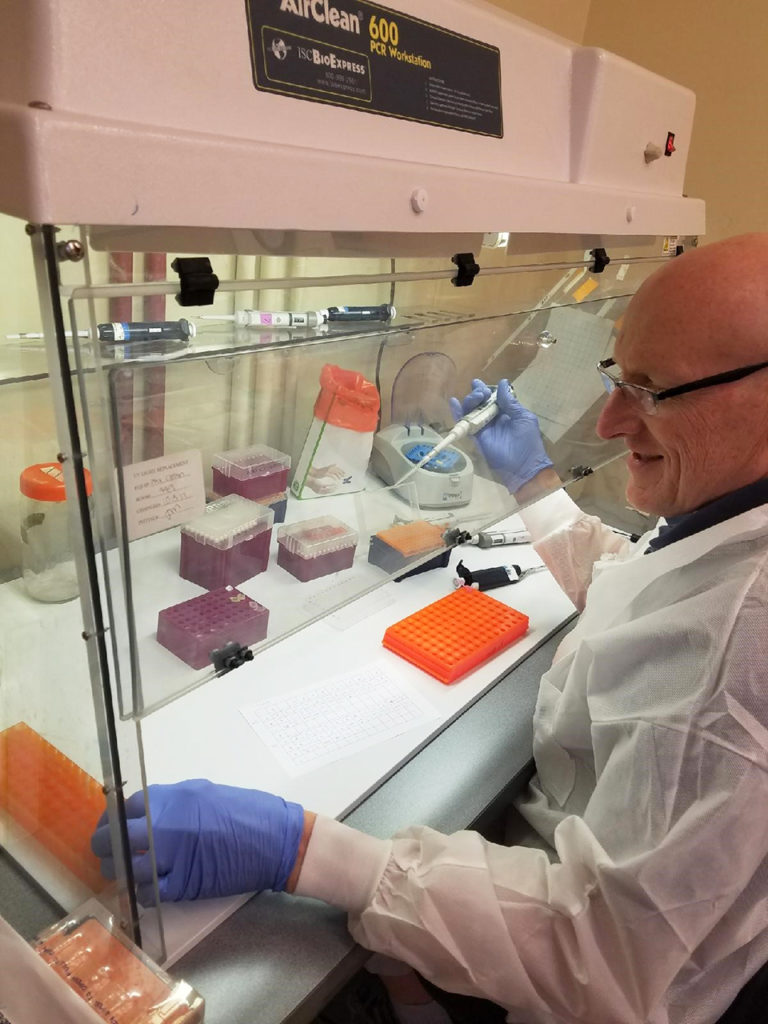

Worker safety

PAA products are all acid stabilized and hence corrosive. All types of handling require precautions such as safety goggles and acid-resistant gloves. Compared to formalin, which is a severe nasal/pharyngeal irritant and considered carcinogenic, PAA is relatively harmless.

PAA products have a pungent smell and should be stored in a place with ventilation. Containers for PAA products have pressure caps, and PAA should not be decanted from large to smaller jars.

Organic requirements

Several Danish rainbow trout producers have been certified organic. According to European Union requirements, at least 50 percent of the ova/fry used should be reared organically. In January 2016, all organic fish production has to be based on certified organic fry. This has put even more focus on optimizing water quality and implementing disinfectants in an organic context to replace formalin.

Low-dose, continuous PAA application has shown promising results for a couple of organic fry producers. The treatment procedure is effectively controlling white spot disease in the critical summer period, which normally sees the addition of formalin, and the application has not led to the discharge of unwanted chemical residuals.

Periodic outbreaks of latent diseases such as rainbow trout fry syndrome, red mouth disease or furunculosis are expected to be less frequent when water quality is good and kept stable under PAA treatment.

Issues, improvement

Optimal application of PAA is not easy. The recommended dosage guidelines depend on the product applied and the system to be sanitized. As a rule of thumb, a concentration of 0.2-0.5 mg PAA/L is typically sought. This concentration is very low, and due to the fact that no test kits are available, expected PAA concentrations are often overestimated compared to actual concentrations.

In the case of controlling white spot disease, PAA application has demands other than those for baths of formalin or sodium chloride. The life cycle of the ICH parasite that causes white spot disease includes a free-swimming stage – theronts – that can be eliminated by disinfectants. Since the theronts are liberated throughout the day, continuous chemical application is needed.

In oligotrophic aquaculture systems, this can be achieved by dripping PAA into the distribution channel that leads to the inlets of the ponds. This has proven effective in some cases, but when system water becomes rich in organic matter, higher dosages – which are more difficult to adjust – are needed.

Continuous PAA application has also been applied to control unwanted pathogens in recirculating aquaculture systems. Preliminary observations show the potential of this and also highlight a potential need for base adjustment if water reuse is significant.

Troublesome parasites such as gill amoebae sometimes cannot be sufficiently controlled on farm by current practices for applying PAA. This often correlates with insufficient solids removal and increased organic matter content. It is expected that hydrogen peroxide, alone or in combination with PAA, can be a complementary chemical agent to ensure proper water quality.

Perspectives

PAA is relatively safe to handle and degrades rapidly, making it beneficial from both worker safety and environmental perspectives. The reactiveness, mode of action and rapid decay, similar to that of ozone, are challenges for aquaculturists and set high requirements for proper dosing.

Recent developments within the industry have accelerated better water treatment practices that now include daily pulse additions, as well as continuous, low-dose applications. As organic aquaculture systems place added focus on rearing conditions and water quality, PAA is expected to have a pivotal role in the future development of organic aquaculture.

(Editor’s Note: This article was originally published in the May/June 2015 print edition of the Global Aquaculture Advocate.)

Authors

-

Lars-Flemming Pedersen, Ph.D.

Technical University of Denmark

Section for Aquaculture

North Sea Research Centre

P. O. Box 101

DK-9850 Hirtshals, Denmark[107,100,46,117,116,100,46,97,117,113,97,64,112,102,108]

-

Alfred Jokumsen

Technical University of Denmark

Section for Aquaculture

North Sea Research Centre -

Villy Juul Larsen

Niels Henrik Henriksen

The Danish Aquaculture Organisation

Silkeborg, Denmark

Tagged With

Related Posts

Health & Welfare

Linking water treatment practices and fish welfare

Quantification of fish behavior is complex and depends on the experimental setup and biomarkers applied. A simple method was tested to quantify locomotor behavior to evaluate the effects of simulated water treatment scenarios using peracetic acid.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 1

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors investigated the problem holistically.

Aquafeeds

Biosecurity protocols needed for shrimp feeds, feeding practices

Shrimp aquafeeds – live, fresh or formulated – should not be an entry point of potential pathogens to the shrimp and/or to their culture systems.