As seafood enters the ‘clean meat’ world, questions remain. Are consumers ready for it? And what is it, exactly?

Would you eat beef that did not come from a cow? Or a tuna that never spent a moment at sea? Put it this way: Would you eat animal protein cells that were replicated in a laboratory to be identical – on a genetic level – to that steak or tuna loin?

Millions of dollars in venture capital are hoping enough of you will say yes.

Lab-grown meat has made headlines recently, as different companies have worked to develop meat products grown from animal cells. A few seafood startups have now joined the “clean meat” trend. Finless Foods and BlueNalu, companies which earlier this year announced seed rounds of $3.5 million and $4.5 million, respectively, say they can bring real seafood products to market in a way that is humane, won’t contribute to overfishing and won’t need to be fed precious marine resources.

In order to get there, they’ll need to overcome challenges including cost, regulation, and consumer acceptance. Some proponents say lab-grown fish meat will find its place in the seafood marketplace.

“We’ve seen that people are willing, over time, to adapt to new product categories, and I think that can happen, because there’s a strong demand for healthy proteins,” said Georg Baunach, cofounder and development director of Hatch, a Norway-based aquaculture accelerator program that invested in the cellular seafood startup Finless Foods earlier this year.

Petri dish to plate

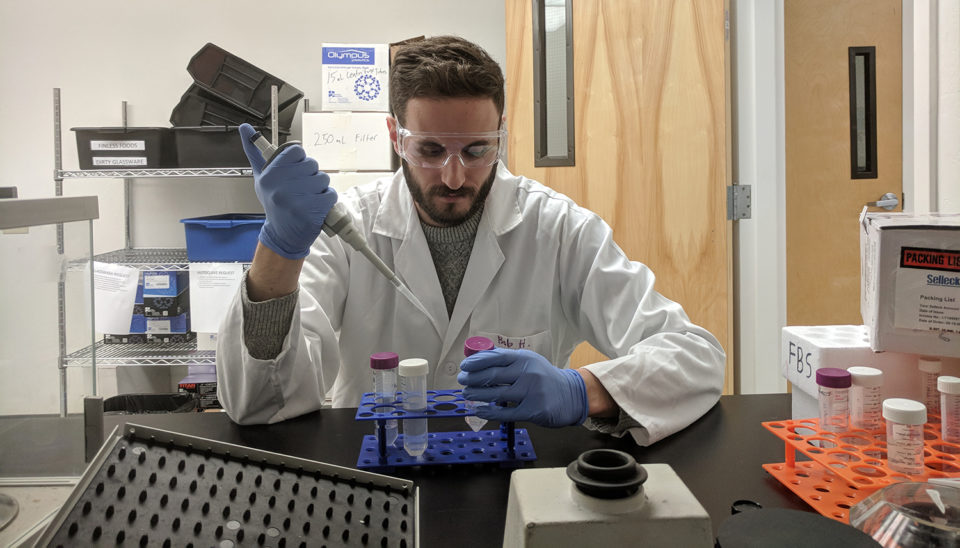

Fish meat can be grown in a lab in much the same way as the meat of terrestrial animals. The process begins by taking a sample of flesh from a real fish, and isolating cells that can be grown into different types of tissues, according to Finless Foods co-founder Michael Selden. Technicians differentiate these starters to form muscle, fat and tissue cells, then place them in a bioreactor in a culture medium, and feed them nutrients including sugars and proteins, causing them to grow. This process yields an “unstructured” product, akin to fish paste.

Developers can then use collagen as a scaffolding on which muscle and fat cells can grow, creating structured fish meat forms like steaks and fillets.

“The structuring is a bit further off,” said Selden. “We believe the first things we’ll bring to market will be unstructured.” Finless Foods prototyped “carp cakes” last year with its unstructured fish product and is now working on building structured products like fillets and sashimi.

Fish meat is actually easier to grow in a lab than land-based meat cells, Selden noted. That’s partly because fish live underwater at cooler temperatures – unlike land animals, fish cells don’t require carbon dioxide inputs in order to grow. Fish cells can also be cultured at a lower temperature, reducing heating costs, and are more tolerant of temperature variation.

Selden sees many advantages to growing fish meat in a lab.

“We can cut down on mislabeling, we can cut down on food spoilage and we can cut down on food-borne illnesses, as well as travel time,” he said. “We can produce this in the center of cities, instead of hauling it inland from the ocean.”

And by using cells, companies like Finless Foods can produce seafood made to order.

“If people want only fish fat, we can do that. If they want lean meat we can do that,” he said. “We can create the most valuable cut of a fish every time.”

The $19,000 fish cake

Protein produced using few inputs and with little, if any, environmental impact? Sounds great, but what’s the catch?

“Our biggest challenge is reducing costs,” Selden acknowledged. The “carp cakes” Finless Foods tested last year cost $19,000 per pound. But Selden is quick to point out that the company has been able to significantly reduce costs in a short period of time – the company was founded in 2016 – and expects to get it down to a point where it could be commercially viable in the next year.

One step is to use less expensive sugars and proteins to feed cells (the company currently uses scientific-grade inputs but could source the products from commercial manufacturers in the future). Other cost-saving steps include improving the efficiency of protein recycling systems and developing methods to breed cells more efficiently.

“We’re down to $6,000 a pound now, and every day is better,” Selden said.

We’ve seen that people are willing, over time, to adapt to new product categories, and I think that can happen, because there’s a strong demand for healthy proteins.

Another – major – question is regulation. Finless Foods is in discussions with the U.S. Food and Drug Administration (FDA) to determine exactly what permits and approvals are required for lab-grown seafood, and at what point the company can begin testing its products for safety.

“I don’t think anybody 100 percent knows the answer to that, including the FDA themselves,” Selden said.

He hopes for a smooth process, noting that, while lab-grown seafood may be a new product, all of the processes being used to create it have been tested and used successfully in other applications.

“We’re not really inventing new technology,” Selden said. “What we’re doing is putting together pieces of existing technology and using it on a fish system, which hasn’t been done before.”

Once produced, he noted, lab-grown fish meat is genetically identical to meat from a real fish. Selden hopes Finless Foods will be ready to go into production by the end of 2019.

So, what the heck is it?

Even though Hatch has been dedicated to supporting aquaculture startups, investing in Finless Foods was a “no brainer,” Baunach said.

“There was definitely a discussion internally: Is it aquaculture, or what is it?” he said; “But I think if you truly want to be innovative, you need to look for potentially disruptive technologies, and that’s something that we tried to do with Finless Foods.”

The accelerator invested €25,000 in cash, along with in-kind support including connections to researchers, laboratories, markets and seafood industry leaders, Baunach said.

Cell-based seafood could someday replace existing seafood products, or it could find a market as something entirely new – much like tofu came to be accepted by western consumers as a new type of protein, rather than a replacement for meat.

“I personally believe that cell-based will create its own product category in the future, and that will depend on price point, taste, texture and regional preferences,” Baunach said, although he added that cost reduction would be a critical challenge to overcome.

Jayson Lusk, a food and agricultural economist at Purdue University, who is not affiliated with Finless Foods, said consumer acceptance is an important question. He has conducted consumer surveys that included questions about whether respondents would eat meat grown in a lab.

“Not many people say yes,” he said.

At the same time, the environmental and animal-welfare benefits of lab-grown products might be a bigger selling point for meats like beef and pork than seafood, Lusk added. Issues like overfishing haven’t received as much media coverage as climate change and the high environmental cost of the livestock industry, he said. Further, many consumers that are concerned about the humane treatment of animals are more focused on pigs and cows than fish, he noted.

Still, while people have historically been slow to accept new food technologies, and regulation has been a stumbling block for some biotech foods, consumers have shown a willingness to adapt over time.

“Most of the surveys I’ve seen have shown skepticism of cell-based technology,” Lusk said. “But I would also say most people don’t know much about it. My gut feeling is at the end of the day, it will come down to ‘how does it taste?’ and ‘what is it priced?’”

Follow the Advocate on Twitter @GAA_Advocate

Author

-

Ilima Loomis

Ilima Loomis (ilimaloomis.com) is a freelance writer in Hawaii who covers science, travel and business.

Tagged With

Related Posts

Health & Welfare

Born in Hawaii, SPF broodstock shrimp industry faces globalization

The next step for shrimp breeding will be developing animals that aren’t just disease-free, but increasingly resistant to multiple pathogens. The industry is globalizing, with suppliers setting up shop overseas. But its birthplace will always be Hawaii.

Health & Welfare

The unmet promise of pondside PCR

A new generation of technology, portable PCR, offers potential for affordable, immediate, pondside diagnosis in easy-to-use handheld kits. But will it live up to the hype?

Responsibility

Two years after shutdown, California oyster farm remains a community hot-button

When one of California’s oldest oyster farms was shut down amid reports that it was degrading the environment, local observers took notice. Two years later, the case is still far from closed in the eyes of the farm’s supporters and its critics.

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.