Biotech startup KnipBio is scaling up production of a single-cell organism as a sustainable aquaculture feed ingredient

Lowell, Massachusetts, is one of many old New England mill towns seeking reinvention. Brick buildings that once served as textile mills along the Merrimack River, before lying dormant for years when manufacturing jobs vacated places like Lowell, now house new ventures – offices, shops, theaters and even an apothecary.

Amongst these reawakening giants stands a newer structure, with a modern mission. On the fourth floor of the UMass-Lowell Innovation Hub is a laboratory where, possibly, a reinvention of aquaculture is growing. Quite quickly, as it turns out.

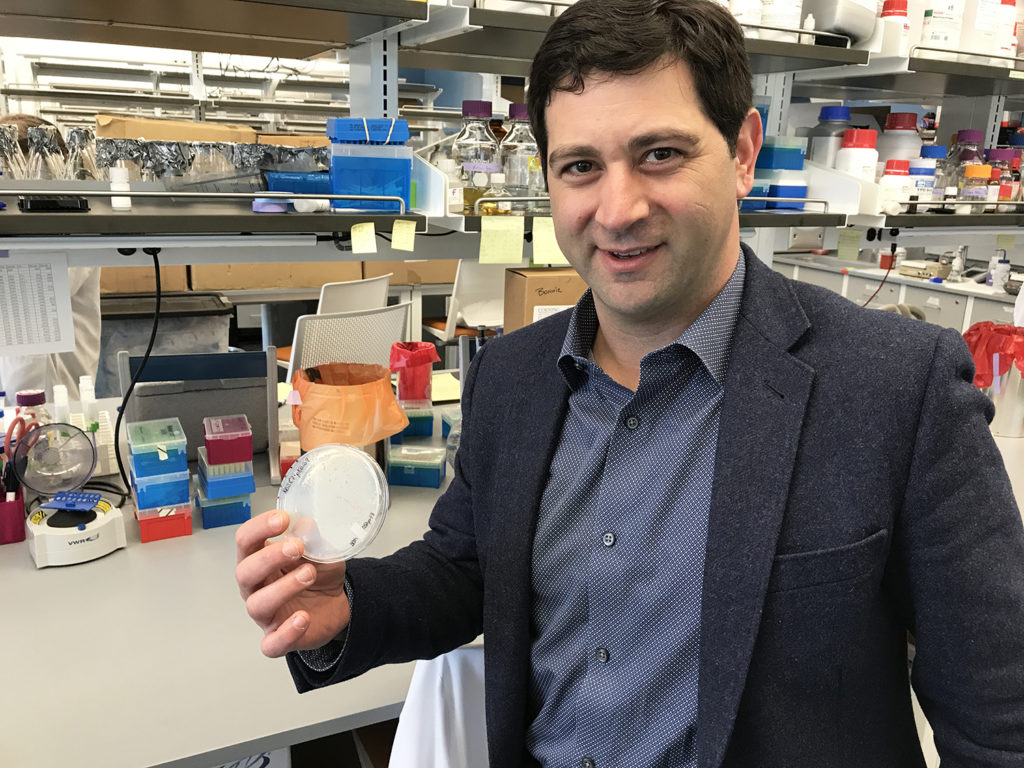

KnipBio, a biotechnology startup founded in 2013 by Larry Feinberg, is refining the manufacturing process for KnipBio Meal, a promising aquaculture feed ingredient. This product – born not at sea but on petri dishes – is derived from the single-cell organism methylobacterium (Methylobacterium extorquens). And it may one day form the foundation of the food that many farmed fish eat.

We think of ourselves as Intel Inside: We’re not selling the computer, but the chips inside of it. We can dial in the amino acid composition, we can dial in the carotenoid expression level.

At first blush, it’s a pink, fine powdery substance, not unlike a flour. As part of a formulated fish feed, it would provide protein and other essential ingredients for popular species like salmon, trout and shrimp. Feinberg told the Advocate that the product will be market-ready as early as next year.

“There’s a lot of momentum right now,” Feinberg said. “We’re putting together a regulatory dossier. We’re scaling up, doing adoption-type cycle animal trials with partners. It’s all about manufacturing as much as the market wants to consume, and being able to manufacture more, and keeping these things on pace.”

Feinberg, who studied ancient and alien life forms in college, prefers to focus on the challenges facing Earth, and he “unapologetically” believes in the role that biotechnology will play in the food systems of the future.

“I’ve been a vegetarian; haven’t had red meat since 1998,” Feinberg quickly revealed. “It’s something that’s always deeply resonated with me: my impact on the planet.”

The UMass alum and microbiologist by training began working with cellulosic biofuels – converting substances like wood chips and grasses into ethanol and other non-petroleum fuels. But the landscape for the field of alternative fuels changed, Feinberg said, when North America’s bountiful natural gas resource was revealed.

“It turned out that Saudi Arabia was under our feet,” he said, referring to shale and modern extraction techniques, like hydraulic fracturing, or fracking. “As I was working on biofuel construction projects, particularly one in Canada, my calls stopped getting returned as quickly.”

Feinberg, a self-described “problem solver,” changed gears and set his sights on food. He introduced himself to Chris Marx, Ph.D., a molecular and evolutionary biologist who became his co-founder at KnipBio. Marx had been working with methylobacterium, a single-cell organism that, in nature, is a leaf symbiont that grows on plant leaves.

“There’s some methanol that sweats off the plants. As the cells divide, they’re eating that alcohol. And then as leaves and fruit drop, there’s alcohol, like ethanol, and they’re able to eat that as well. Because it’s sitting on the surface, it’s being bathed in sun the whole time, and it’s got these carotenoids it uses as a sunscreen.”

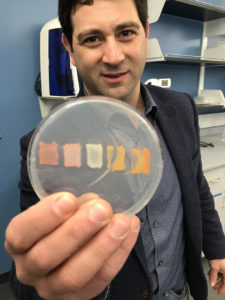

KnipBio Meal – a dried and processed form of the microbial biomass – is produced via a fermentation process. Certain forms of it can contain astaxanthin carotenoids, which are important to aquaculture for the pink flesh coloring needed by farmed salmon, trout and shrimp.

But unlike the commonly used and chemically synthesized astaxanthin, KnipBio’s single cell proteins can be fine-tuned to custom-fit aquaculture feed formulations based on species, specific dietary needs like taurine, or the overall rate of inclusion of the ingredient.

“We are a protein-plus. The question is, ‘Can we compete against chemically produced carotenoids or amino acids in addition to the cost of protein, to have equal or better performance, at equal or lower cost?’ I’m pretty sure that answer is yes on both fronts,” said Feinberg. “We think of ourselves as Intel Inside: We’re not selling the computer, but the chips inside of it. We can dial in the amino acid composition, we can dial in the carotenoid expression level.”

The organism itself feeds on methanol derived from natural gas, which is currently an abundant and affordable resource. And it grows fast, with the fermentation process taking just 38 to 40 hours – a new strain is being developed every week. “We have hundreds of strains in our library,” he said.

“What’s interesting about that feedstock (methanol) is it’s not something that’s going to compete for food with people, like sugars, or terrestrial proteins like soy,” said Feinberg. “[If you] take something you have a lot of and convert it into something you have less of, it’s typically a good economic principle.”

Converting an abundant carbon source, such as methanol and methane, into an edible biomass is an emerging field in biotech. An established competitor for KnipBio is Calysta, a California-based company that converts the feedstock methane into a single-cell organism, which it manufactures into a pelleted animal feed. Last year, Calysta partnered with feed giant Cargill to build an industrial gas fermentation facility in Tennessee, the construction of which began last week. It had previously announced a “market introduction facility” in Teesside, England.

“They bring a lot of positive attention to this space. They are very good at making people aware of the opportunity to use a single-cell organism in aquafeeds and beyond,” said Feinberg. “But we didn’t have to build a gas-direct facility. We use a third-party manufacturing facility, and we’ve been piloting this since 2014”.”

The two biotechnology companies’ processes have similarities, but diverge at important points, said Feinberg: in the manufacturing process, and in the products themselves.

In the way that we see NGOs not as passionately against fish farming, I think that’s what’s going to begin with biotechnology.

“When you try to put methane, or any gas, into a solution and you require oxygen, you’re talking about not just a flammable substance but a potentially explosive one. Oxygen – their process is two times more oxygen-intensive than ours – plus methane, plus pressure … you’re talking about, at the very least, a more expensive plant because of all the safety concerns.”

Methanol, on the other hand, is highly soluble, so there are no concerns about the bacterium “seeing” the food. “It gets to it. It’s like milk in coffee,” said Feinberg, who hopes the conversation around biotechnology and genetically modified organisms (GMOs) continues to evolve.

He sees it this way: GMO 1.0 was productivity to the farmer, such as Roundup Ready soybeans. GMO 2.0 was productivity to the farmer plus benefits to the consumer, like non-browning apples or omega-3 canola oil.

“GMO 3.0 is what KnipBio is working on: Take those first two and add environmental stewardship,” said Feinberg. “I think, ultimately, the pendulum is start to swing on this kind of thinking. In the way that we see NGOs not as passionately against fish farming, I think that’s what’s going to begin with biotechnology.”

Author

-

James Wright

Editorial Manager

Global Aquaculture Alliance

Portsmouth, NH, USA[103,114,111,46,101,99,110,97,105,108,108,97,101,114,117,116,108,117,99,97,117,113,97,64,116,104,103,105,114,119,46,115,101,109,97,106]

Tagged With

Related Posts

Aquafeeds

Bridging the omega-3 gap with methane, microalgae

Innovation is leading to new ingredient options for renewable sources of omega-3 fatty acids. But Replicating long chain fatty acids is a tall order, Advocate contributor Lisa Duchene discovered.

Aquafeeds

Buggin’ out: Tapping the potential of insect meal in aquaculture

Black soldier flies are gaining interest as a leading alternative ingredient in aquafeeds. But will the “ick” factor be a turn-off? Advocate contributor Clare Leschin-Hoar investigates.

Aquafeeds

Talent show: Aquafeed companies show off at F3

Aquafeed manufacturers and alternative feed ingredient suppliers from all over the world gathered in Silicon Valley for F3, the Fish Free Feed contest. In the hub of innovation, solutions to a global problem were on full display.

Aquafeeds

Aquaculture Exchange: Rick Barrows

After 14 years with the USDA’s Agricultural Research Service, Rick Barrows talks about the importance of finding ‘complete’ and commercially viable alternative sources of omega-3 fatty acids and continuing innovation in the aquafeed sector.