Ragworms have proven to be efficient food converters

Two companies, INVE and Seabait, have recently joined forces to make the latter company’s product, the ragworm (Nereis virens) available to the aquaculture industry worldwide. A specific process is being applied to these worms, under culture conditions, to make them better suited to the industry needs, and several characteristics make it a unique product.

INVE is a group of companies of Belgian origin devoted to aquaculture nutrition, with a special focus on the critical stages of reproduction and larviculture. Seabait, Ltd is a U.K.-based company that started commercial culture production of the ragworm, Nereis virens, in 1985. For years, Seabait has devoted its work to the production of live worms for the demanding bait and recreational fishing market.

It is noteworthy that, because of its achievements in environmental protection, Seabait, Ltd has earned several awards. The farm is located on the Northeast coast of England, totally isolated from potential disease contamination from shrimp and temperate marine fish.

Fresh, semi-formulated, and formulated feeds

Maturation of marine fish and shrimp typically relies heavily on freshfrozen feeds, such as squid, fish, marine worms and mollusks, and only lightly on formulated feeds.

Fresh feeds are wild-caught and are usually selected according to their availability. A variety of organisms is preferred to “harmoniously” balance the broodstock nutrition. This is more a “concept of nutrition” than a science, but will usually show moderate to good results due to the nutritive value, high palatability and digestibility of these feeds. Limitations of fresh feeds include limited availability, lack of consistency and nutritional value, lack of quality control, and lack of potential for improvement.

Formulated feeds are already available in the market, and are formulated according to the latest nutrition research and knowledge. One of their major advantages, in terms of dry or semi-moist formulas, is that they will significantly increase the broodstock intake (in terms of feeding higher dry weight). Unfortunately, compound feeds have lower attractability and lower palatability that limit their use. Based on available information, pellets will usually not perform as well as fresh-feeds, especially at high replacement levels. But this is undoubtedly where the future of maturation diets is, and there is more research and technology coming in the near future.

Semi-formulated feeds used to be a one-player category: enriched artemia biomass. These feeds are able to combine benefits of fresh and compound feeds, such as more regular availability, high attractability and digestibility, with a strict quality control and improved nutritional value. But these feeds remain limited by some external factors, such as exceptional bad weather conditions, natural productivity, and others.

Ragworm production system

All broodstock, reproductive and grow-out phases are carried out inhouse, as a true, self- sustaining farming operation. Based on years of research, in close cooperation with the University of Newcastle, Seabait has developed and patented a larvae cryopreservation process that allows yearround availability of larvae for stocking.

Larviculture is conducted indoors in a hatchery, under strictly monitored conditions until the juvenile worm reaches its benthic stages. Farming is done in shallow, sandy concrete ponds fed by temperature-regulated waters (around 15 degrees-C). The production system is intensive with yields as high as 3 kilograms per square meter at harvest. The intensive system facilitates routine observation, good health, and low disease risk. Buried in the sand during daytime, the worms have a higher activity level by night and swim into the water column often.

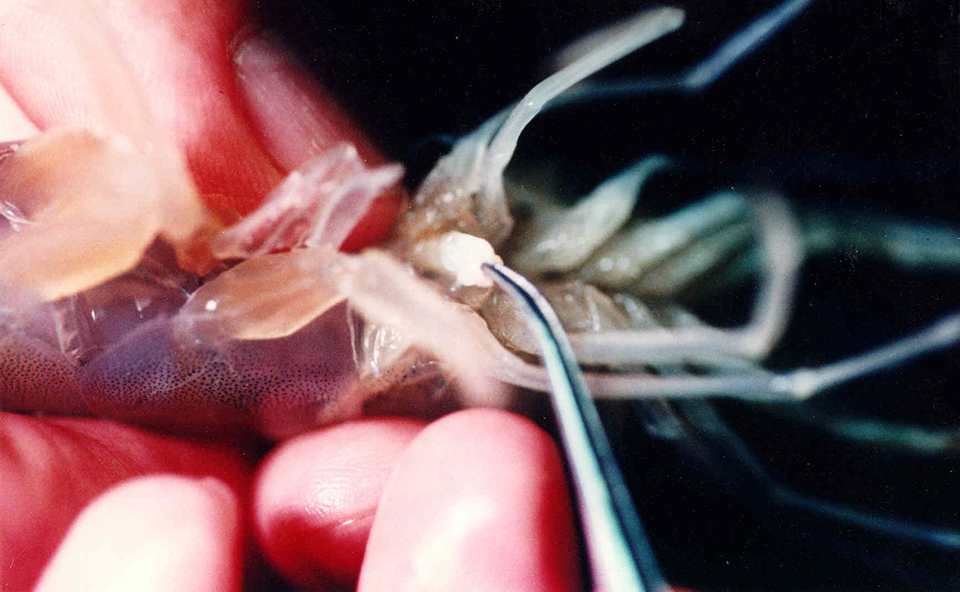

They are fed a specialized diet predominantly of terrestrial origin. Interestingly, they show a very strong feeding behavior in which they leave their tunnels in search of food within minutes of a feeding. Harvesting involves the use of a sludge pump and sieving on a dewatering device so that worms can be collected alive. After harvest, the animals are cleaned and purged for 24 hours in clear water, to remove external debris and gut content. Because of Seabait’s extensive experience with live baits, the worms are guaranteed to arrive alive at the freezing process for blast freezing or nitrogen freezing. This improves recovery rate (wet weight after thawing vs. gross weight frozen), an important quality indicator. They are routinely sorted, selected, and checked live before being packed in small carton boxes and frozen. The current production rate is several tons per month, and capacity exists for expansion.

Nutritive value

Ragworms have soft bodies and high levels of digestible protein. Their very thin cuticle makes the animal very palatable and easy to consume, even by small animals such as shrimps. Worms are rich in highly unsaturated fatty acids (HUFAs), which are essential nutrients for most marine organisms. Nutritional composition is not affected by environmental changes, nor does it vary by size or age changes. Several months of use at shrimp maturation hatcheries in Ecuador have yielded good production results.

Pinon, Total lipid and fatty acid composition of Seabait cultured ragworms, Table 1

| % Dry Weight | 22 |

| Total Lipid (mg g-1 DW) | 272 |

| EPA (mg g-1 DW) | 12.5 |

| DHA (mg g-1 DW) | 4.2 |

| ARA (mg g-1 DW) | 8.2 |

| DHA/EPA Ratio | 0.34 |

Table 1. Total lipid and fatty acid composition of Seabait cultured ragworms (Nereis virens).

The next step: formulated live feeds?

Why not produce a live food organism formulated to one’s specifications? Combining the knowledge of farming marine worms with that of aquaculture nutrition may provide new opportunities to combine the benefits of live and formulated diets. We have already started joint research and experimental programs to study the nutritional dynamics of ragworms. Some potential applications include:

- Tailor made product: customized size, age, maturity, etc.

- Planning and cost control: being a manufactured product, planning, ordering and projection are possible.

- Manipulated composition: ragworms have proven to be efficient food converters, and this characteristic should be manipulated and capitalized upon. Changes in the animal’s composition were documented through changes of feeding regime and rearing conditions.

- Superior feed: having all the advantages of a fresh feed; adaptation will make it possible to target nutrition for different species of fish or shrimp.

- Additional worm species: other species of marine worms are in various stages of development for mass culture, and may bring new benefits in the future.

(Editor’s Note: This article was originally published in the April 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Eric Pinon

INVE del Ecuador

(INVECUADOR S.A.)

Cdla. Las Conchas, Mza. A-11

Salinas – Guayas Ecuador

[99,101,46,109,111,99,46,97,117,99,101,45,101,118,110,105,64,110,111,110,105,112,101]

Tagged With

Related Posts

Aquafeeds

Maturation diets for male shrimp: Fresh food vs. formulated feeds

Maturation diets for shrimp broodstock often include fresh food organisms like squid, bloodworms and fish, which is labor-intensive and involves quality and safety issues.

Health & Welfare

Broodstock shrimp nutrition, a review

Research into broodstock shrimp nutrition will be a key element in the further use of domesticated and genetically selected stocks for aquaculture.

Health & Welfare

Flatworms potential harvesters of antitumor compounds

Tiger flatworms hold promise as a source for ecteinascidins, a class of antitumor compounds under study for human cancer treatment.

Aquafeeds

CSIRO studies dry feeds for juvenile spiny lobsters

The Commonwealth Scientific and Industrial Research Organisation has researched pelleted dry feeds are palatable to juvenile tropical spiny lobsters.