ISP allows high protein recovery yields while significantly reducing fat content

Functional or nutraceutical food products contain added, technologically developed ingredients with specific, well-documented health benefits. These foods provide a means to achieve the desired health effects without the ingestion of dietary supplements or medications, or a major change in dietary habits.

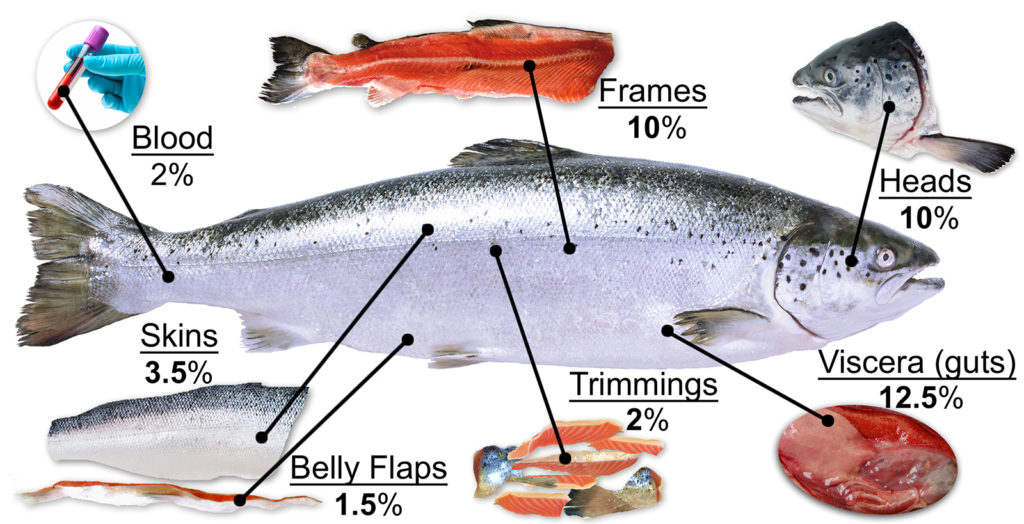

When raw seafood is processed in commercial settings, significant quantities of byproducts are generated. These processing by-products contain residual meat and that adheres to bones and skin. The by-products typically have to be properly disposed of, often causing processors to incur extra cost. However, if this residual meat were efficiently recovered, it could be used as the main ingredient to develop nutraceutical seafood products.

The recovered meat would provide the bulk of the product and properties such as gelation and water-holding capacity, while nutraceutical ingredients that provide omega-3 fatty acids, soluble dietary fiber and salt substitution could be added in lesser amounts to provide the nutraceutical function.

ISP technology

Isoelectric solubilization/precipitation (ISP), which has been applied to fish, beef and chicken byproducts, is a technology that also allows efficient recovery of the residual meat from seafood processing byproducts. ISP allows selective, pH-induced water solubility of muscle proteins with concurrent separation of lipids and removal of materials not intended for human consumption such as bones, scales, skin, etc.

ISP allows high protein recovery yields while significantly reducing fat content in the recovered protein isolates. Muscle proteins from fish have thus far been recovered using batch-mode ISP at laboratory and pilot scales.

Recovered fish protein isolates retain functional properties and nutritional value, which is critical for the development of nutraceutical seafood products. Due to extreme pH shifts, ISP also results in up to 5-log non-thermal microbial reduction.

Prototype products

Prototype nutraceutical seafood products were developed in a food science laboratory at West Virginia University. The main ingredient was a protein isolate recovered with ISP from whole, gutted striped bass, which retained their heads, bones, skins and scales. The fish were ground and homogenized with water at a 1:6 ratio. Fish muscle proteins were dissolved at pH 11, followed by removal of insoluble bones, skin and scales by centrifugation.

The dissolved protein fraction was collected, and its pH was adjusted to pH 5.5, the isoelectric point of fish muscle proteins, at which they precipitate. The precipitated proteins were dewatered by centrifugation, yielding a fish protein isolate.

A paste was obtained from the isolate by extracting myofibrillar proteins with a commercial potassium chloride-based salt substitute at a level equivalent to 2 percent sodium chloride, a typical amount added to restructured meat products, in a universal food processor.

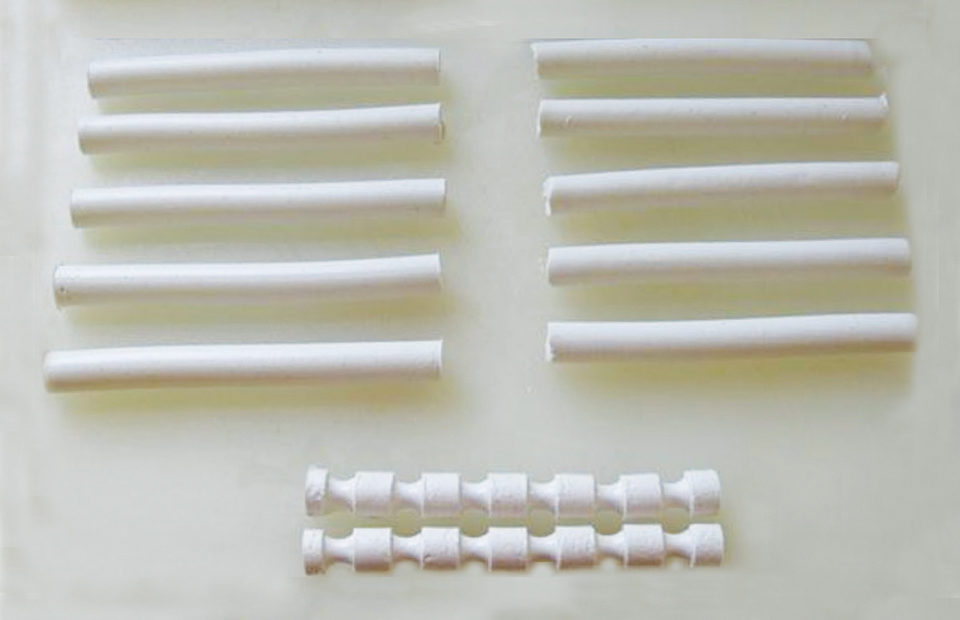

A combination of flaxseed oil and fish oil rich in polyunsaturated omega 3 fatty acids was added to the paste at a level of 10.0 percent, along with 4.0 percent commercial soluble fiber. In addition, 0.5 percent of a commercial microbial transglutaminase and 0.5 percent of titanium dioxide were added. Transglutaminase is often used to enhance texture, while titanium dioxide is commonly added to food products at up to 1 percent as a whitening agent. When uniformly mixed, the paste was stuffed into stainless 1.9-cm-diameter tubes and cooked at 90 degrees-C for 15 minutes.

The ISP-recovered fish protein isolate retains gel-forming ability and so can be molded or extruded in various shapes, such as sticks, fingers or nuggets. Table 1 lists the content of the nutraceutical ingredients in the cooked nutraceutical seafood product in comparison to some current neutraceutical food products on the market and recommended levels for these nutrients.

Jaczynski, Ingredient levels of seafood, Table 1

| Ingredient | Recommended Intake | Nutraceutical Seafood Product | Commercial Nutraceutical Products |

|---|---|---|---|

| Sodium content | 1,500-2,300 mg | Below 100 mg | Surimi stick, 850-mg sodium |

| Total omega 3 | 1,500 mg | 3,000 mg | Soy milk – 32 mg DHA Milk – 50 mg total omega 3 PUFAs Eggs – 200 mg total omega 3 PUFAs Bread – 225 mg ALA Spread – 329 mg ALA Buttery spread – 32 mg EPA + DHA |

| a-linolenic acid (ALA) | – | 2,000 mg | Soy milk – 32 mg DHA Milk – 50 mg total omega 3 PUFAs Eggs – 200 mg total omega 3 PUFAs Bread – 225 mg ALA Spread – 329 mg ALA Buttery spread – 32 mg EPA + DHA |

| Docosahexaenoic acid (DHA) | Combined DHA + EPA 250 mg | 500 mg | Soy milk – 32 mg DHA Milk – 50 mg total omega 3 PUFAs Eggs – 200 mg total omega 3 PUFAs Bread – 225 mg ALA Spread – 329 mg ALA Buttery spread – 32 mg EPA + DHA |

| Eicosapentaenoic acid (EPA) | Combined DHA + EPA 250 mg | 500 mg | Soy milk – 32 mg DHA Milk – 50 mg total omega 3 PUFAs Eggs – 200 mg total omega 3 PUFAs Bread – 225 mg ALA Spread – 329 mg ALA Buttery spread – 32 mg EPA + DHA |

| Fiber | 25-38 g | 4 g | None in seafood |

Perspectives

Although this prototype supports the possibility of utilizing low-value seafood processing by-products to develop high-value nutraceutical seafood products, sensory tests and storage stability studies are recommended.

To capitalize on the popularity of deep-fried foods, it would be desirable to develop a reduced-fat fried product whose main ingredient would be the ISP-recovered fish protein isolate with the added neutraceutical ingredients. Such a product can likely be developed by dry-heat pre-baking the protein paste to create a crust on the outside, followed by deep frying.

The crust will likely prevent excessive absorption of oil and moisture loss during frying, but the high temperature will result in rapid heat transfer and consequent crunchy/crispy texture and flavor. The author’s laboratory is currently working on optimization of several parameters for such a reduced-fat, deep-fried seafood product.

(Editor’s Note: This article was originally published in the January/February 2012 print edition of the Global Aquaculture Advocate.)

Author

-

Jacek Jaczynski, Ph.D.

Associate Professor of Food Safety

Animal and Nutritional Sciences

West Virginia University

P. O. Box 6108

Morgantown, West Virginia 26506-6108 USA[117,100,101,46,117,118,119,46,108,105,97,109,64,105,107,115,110,121,122,99,97,106,46,107,101,99,97,106]

Tagged With

Related Posts

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.

Health & Welfare

Animal health giants have sea lice in their crosshairs

Alltech and Benchmark have been working on the next generation of sea lice solutions and believe they have new products that can help salmon farmers win.

Aquafeeds

Aquaculture Exchange: Giovanni Turchini, Deakin University, part 1

One of the world’s leading fish nutrition experts talks about how aquaculture can learn to survive, and even thrive without depending on fishmeal and fish oil. It’ll take a lot of innovation, but Giovanni Turchini is confident that the industry is on the right path.

Aquafeeds

It takes guts to advance sustainability in aquaculture

With byproducts representing between 25 to 50 percent of the weight of various fish species, we need to be looking at how the entire fish is being used: even the heads, guts and skin.