Sodium carbonate peroxyhydrate not yet FDA approved

Fungal infections caused by organisms of the genus Saprolegnia are a significant problem for many commercial catfish hatcheries. Dead eggs and other organic matter in hatchery culture systems provide excellent substrates for these ubiquitous freshwater molds.

Without chemotherapeutic treatment, pathogens quickly infect moribund eggs and spread to live eggs, overtaking the egg mass. If left untreated, embryo survival reduces to zero. Even with treatment, hatch rates from infected egg masses can be significantly reduced.

Current treatments

Immersion treatments with chemical therapeutants such as formalin and hydrogen peroxide are often used to prevent and control potential infections. Formalin and hydrogen peroxide are currently the only therapeutants approved by the U.S. Food and Drug Administration (FDA) for immersion treatment of catfish eggs.

Formalin is specifically approved for controlling saprolegniasis fungal infections on fish eggs. Although formalin is an effective egg disinfectant, there are safety concerns among commercial hatchery staff due to its odor and suspected carcinogenicity.

Hydrogen peroxide provides an effective alternative to formalin as an egg disinfectant. Studies conducted at the Thad Cochran National Warmwater Aquaculture Center in Stoneville, Mississippi, USA, from 2001 to 2003 demonstrated that when administered as a 15-minute static bath treatment, a concentration of 250 mg hydrogen peroxide per liter of hatchery water yielded 42 percent higher hatch rates than for untreated eggs reared under similar conditions and management.

Unfortunately, 15-minute bath treatments in commercial hatcheries can be a substantial risk, with millions of eggs lost in the event treatment time is not monitored closely. As an alternative, the researchers also found that a 70 mg per liter hydrogen peroxide solution yielded the best performance in continuous-flow incubation troughs with hatch rates similar to or better than those obtained with formalin treatment.

Unlike formalin, hydrogen peroxide has little odor and is not considered potentially carcinogenic. Hydrogen peroxide has the added benefit of being considered environmentally friendly since it decomposes into water and oxygen. However, hydrogen peroxide has not been well received by commercial hatchery staff because, as a strong oxidant, liquid hydrogen peroxide can irritate and burn their skin.

Disinfection alternative

In an effort to find an alternative to formalin and hydrogen peroxide, the author sought a chemical with strong oxidizing potential, no odor or carcinogenicity, and easy and safe use in a hatchery setting for evaluation as an egg disinfectant. Sodium carbonate peroxyhydrate (SCP), commonly called sodium percarbonate, appeared to meet the desired attributes.

Sodium percarbonate is a free-flowing granular substance made by combining two molecules of sodium carbonate with three molecules of hydrogen peroxide, thus yielding a 32 percent-hydrogen peroxide compound. When added to water, SCP breaks down into hydrogen peroxide and sodium carbonate. As a relatively stable solid, SCP has no significant storage issues.

Sodium percarbonate products are marketed in the United States as fast-acting algaecides or algaestats. Several brands of SCP are on the market as U.S. Environmental Protection Agency (EPA)-registered algaecides for use in ponds, lakes, reservoirs and drinking water.

SCP trials

Researchers at the Thad Cochran National Warmwater Aquaculture Center decided to evaluate SCP as a treatment for improving channel catfish hatch rates because hydrogen peroxide is the active component of SCP and is itself an effective chemotherapeutant for treating fungal egg infections. It also appears that the oxidizing potential of hydrogen peroxide is not lost in the SCP compound based on its efficacy as an algaecide.

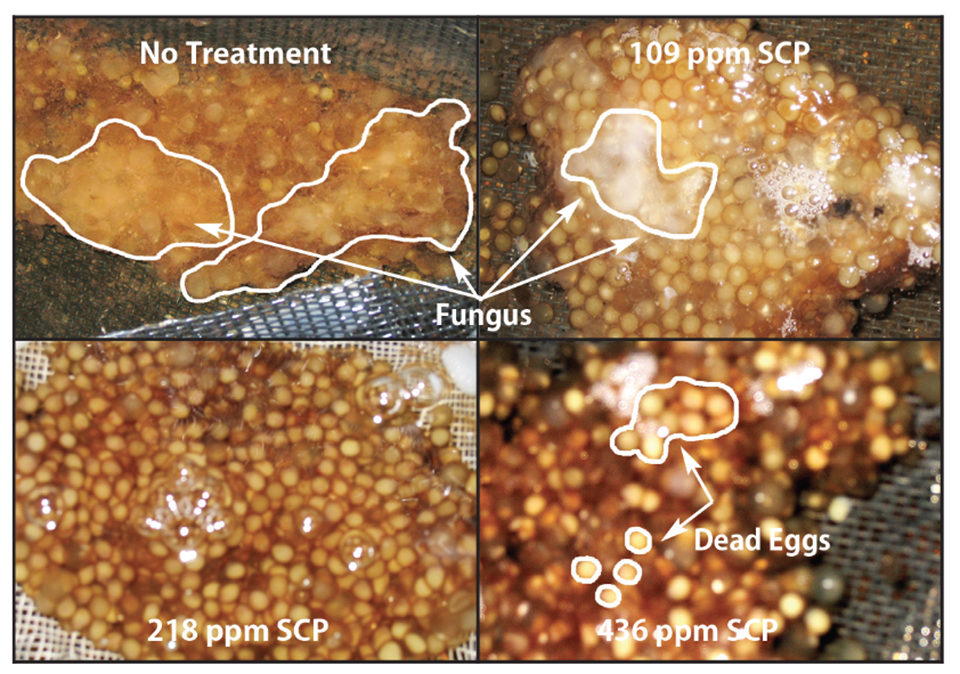

In studies, channel catfish egg masses were split into fourths and placed into individual hatching baskets in commercial-type hatching troughs. Egg masses were treated daily with SCP at concentrations of 0, 109, 218 and 436 mg per liter – levels that correspond to hydrogen peroxide concentrations in the troughs of 0, 35, 70 and 140 mg per liter, respectively, based on SCP being 32 percent hydrogen peroxide. SCP was dissolved in hatchery water and immediately added to the water inlet end of the troughs.

The 218 mg per liter SCP treatment yielded the highest hatch rates, and no saprolegnia was observed on the egg masses in this treatment trough. Fungus was observed with both the 0 and 109 mg per liter SCP treatments, and dead eggs were observed at the highest treatment concentration.

Overall, SCP performed similarly to hydrogen peroxide, with the 218 mg per liter treatment providing the best results. A further side-by-side comparison of SCP and hydrogen peroxide treatments of channel catfish egg masses under the conditions above verified the equivalent efficacy of SCP to hydrogen peroxide for improving catfish hatch rates.

Considerations

Several facts must be considered regarding the use of SCP. Unlike liquid hydrogen peroxide at 35 percent strength, SCP is not currently approved by the FDA for disinfecting fish eggs. Also, in addition to the release of hydrogen peroxide molecules when water is added to SCP, another byproduct is carbonate. In the author’s studies, the carbonate released from SCP caused a substantial increase in hatchery water pH. In water with low buffering capacity or sensitive species, this could be a problem.

However, a short-term benefit in water quality was also observed. Dissolved-oxygen levels increased approximately 0.75 ppm for 20 minutes following the addition of SCP to the incubation trough water.

(Editor’s Note: This article was originally published in the November/December 2008 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Brian C. Small, Ph.D.

USDA, ARS Catfish Genetics Research Unit

Thad Cochran National Warmwater Aquaculture Center

141 Experiment Station Road

Stoneville, Mississippi 38776 USA[118,111,103,46,97,100,115,117,46,115,114,97,64,108,108,97,109,115,46,110,97,105,114,98]

Related Posts

Responsibility

Hydrogen peroxide: Disinfectant for recirculating aquaculture systems

Hydrogen peroxide is a candidate for water treatment in aquaculture systems for it has antimicrobial effects and easily degrades to harmless byproducts.

Health & Welfare

In sea lice fight, salmon farmers phasing out hydrogen peroxide

An over-reliance on medical and chemical controls, along with warming waters, led to a surge in sea lice. With such treatments waning in effectiveness, operators turn to other, safer measures.

Responsibility

Microbial activity assessment based on hydrogen peroxide decomposition rates

Fast, easy, reliable method offers great potential for all aquaculture systems There is a widespread need for cultivation-free methods to quantify the viability of microbial communities in aquatic environments. This demand also exists within the aquaculture industry, where rapid and reliable methods for measuring bacterial activity and bioavailable organic matter in water are increasingly required.

Health & Welfare

Animal health giants have sea lice in their crosshairs

Alltech and Benchmark have been working on the next generation of sea lice solutions and believe they have new products that can help salmon farmers win.