Slurry systems worldwide work for nearly all major seafood species

Rapid cooling of seafood immediately after harvest is key to ensuring quality in aquaculture operations. Typical cooling methods include layering ice with product and ice water baths.

Ice slurry began receiving attention from the marine scientific community 25 years ago for its ability to maximize the chilling speed of fish. Between 1984 and 1988, the Department of Fisheries and Oceans of Nova Scotia, Canada, conducted a systematic study of ice slurry and published a series of reports on the workability, physical characteristics and cooling effects of ice slurry on fish.

Subsequently, fishery institutions around the world – including the Sea Fish Industry Authority of the United Kingdom, Icelandic Fisheries Laboratories and, recently, the Institute for Marine Research of Spain – have conducted further analysis and trials on ice slurry for various fish species.

Today, over 700 slurry systems are installed worldwide. Successful results have been reported for almost all major seafood species, from sardines and salmon to shrimp and lobsters.

Fish quality, yield

Recent reports of microbiological, biochemical and sensorial analyses have concluded that ice slurry is a promising technology to achieve good quality and yield for a wide range of fish species.

While the spoilage rate of fish is considerably slowed when stored in ice slurry, some fish species like seabream are reported to exhibit cloudy eyes when held in a brine-based slurry, which negatively affects the appearance and perceived quality of the fish. This is probably due to the precipitation of an eye component when stored at sub-zero temperatures, at which many current ice slurry systems operate.

Ice slurry produced from seawater can also lead to the problem of salt uptake during extended storage of some fish species like pelagic fish. The challenges are to identify the optimal cooling and storage conditions for each fish product, and then design a system that can accurately control both the temperature and salinity of ice slurry to the ideal level for each application.

Variable-state system

Systems like the variable-state ice slurry system developed by Sunwell Technologies Inc. can control both the ice fraction and salinity of the discharged ice slurry to ensure the ideal preservation mix is delivered.

Brine or seawater is fed by the circulation pump to the slurry ice generator, where salt-free crystals are formed. Ice slurry is then pumped to an ice storage silo where, due to buoyancy, ice crystals separate from the brine and float to the top, forming a porous ice bed. The brine solution in the lower portion of the silo remains in the ice system and is recirculated through the ice generator.

When ice delivery is required, a rotating stainless steel ice “harvester” removes ice crystals from the top of the ice bed and sends them down the delivery chute to a container for dry crystals. Ice can also be discharged to a mixing tank, which blends the ice crystals with water to form pumpable ice slurry for fish cooling and preservation.

Yellowtail processing

Burimy is one of the most successful fish-farming/processing companies in Japan. It processes about 1,500 metric tons (MT) of fish a year, including yellowtail, amberjack, red sea bream, hardtail and Japanese horse mackerel.

Burimy installed a variable slurry ice system to provide constant, low-temperature cooling throughout the harvesting and processing cycle, ensuring the preservation of its fillets and dressed products. The system uses 20 degrees-C seawater to produce as much as 6.6 MT of dry ice crystals or 18.5 MT of slurry ice daily. Burimy wanted to improve quality and improve working efficiency. The slurry system allowed the company to maintain a consistent fish product temperature at just below 0 degrees-C from harvesting all the way to shipping.

Before installing the system, Burimy used a crushed ice and seawater mixture for bleeding fish at the farm and chilling in the processing plant. Early in the morning, two employees stirred ice and water in the bleeding tanks for two hours. They then moved the tanks to the dock and loaded them on the boat that would carry them to the offshore fish cages 15 minutes away.

With the ice slurry system, the process is as simple as pressing a button to pump the ice from the insulated storage tank next to the processing plant to the tanks on the dock, about 180 m away. The ice is delivered with a temperature of -1.7 degrees-C.

The fish are loaded onto the operating boat at the farm and killed quickly with a bleeding machine. When initially placed in the onboard tank, the fish have a temperature of 16 degrees-C.The load is then placed into tanks on the dock containing slurry with a 25 to 30 percent ice fraction.

The holding tanks are delivered to the processing plant, where the fish cool for an additional hour to 4 degrees-C. Even with the fish in the tank, the temperature of the ice remains at -1.5 degrees-C.

The fish are processed, cleaned and once again placed in slurry ice for an additional 30 minutes to bring the fish temperature down to 0 degrees-C. The fillets and ready-to-cook fish are dried off, packed and shipped.

Mussel processing

Other applications of slurry ice extend from shrimp and salmon to mussel cooling and packing operations. In late 2005, Prince Edward Aqua Farms Inc. joined other mussel packers on Prince Edward Island and integrated a slurry system into its existing processing facilities. Slurry ice is used to pack the mussels and ship them fresh to markets across North America.

Jerry Bidgood, general manager of Price Edward Aqua Farms, said: “We wanted an ice system that was fast-cooling, slow-melting and more efficient than our flake ice system. Our goal was to reduce drip loss and increase shelf life by maintaining a colder core temperature, especially during the mussel-spawning season in June and July.”

The system at Price Edward Aqua Farms uses seawater to produce as much as 10 mt of dry ice or almost 20 mt of slurry ice per day. Slurry with an ice fraction of 50 to 60 percent is automatically pumped to four locations at the facility.

At the first two locations, slurry ice is discharged into bulk containers holding 360 to 410 kg of mussels packaged in mesh bags. The mussels are cooled to just above 0 degrees-C. Bidgood said the earlier flake ice system required a lot of manual labor, as ice had to be shoveled into every box and vat.

“The (slurry) system gave us an automatic method for icing that got in between every mussel in every bag, ensuring fast cooling of the entire product,” Bidgwood said. “Comments from our customers are extremely positive, and they don’t wish to go back to flake ice.”

A third discharge location is a chill room used for packing mussels in waxed boxes in 50-, 25- or 10-lb (22.6-, 11.3- or 4.5-kg) configurations. Mesh bags of mussels are placed into the boxes, and ice slurry is discharged over the bags, flowing into every space to provide ultimate contact cooling. The final discharge station is also located in the chill room, over 45 meters away from the ice generators. It is used for packing the bulk containers and waxed boxes, and as a re-icing station to maintain mussels packed on non-shipping days.

“Our customers tell us they can get 10 to 12 days shelf life with our mussels in (slurry) ice,” Bidgwood said. “They say they can only get seven days from our competitor’s product that uses other types of ice.”

(Editor’s Note: This article was originally published in the May/June 2010 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Ming-Jian Wang, Ph.D.

Sunwell Technologies Inc.

180 Caster Avenue

Woodbridge, Ontario L4L 5Y7, Canada[109,111,99,46,108,108,101,119,110,117,115,64,103,110,97,119]

Tagged With

Related Posts

Intelligence

Critical decisions for shrimp harvesting and packing, Part 2

The decision to harvest involves consideration of various factors, including market prices, customers’ need, biomass and condition of the animals and others. Several steps are involved, most aimed at maintaining maximum quality of the animals as they are harvested, sacrificed, treated and transported to the plant and processed and packed.

Intelligence

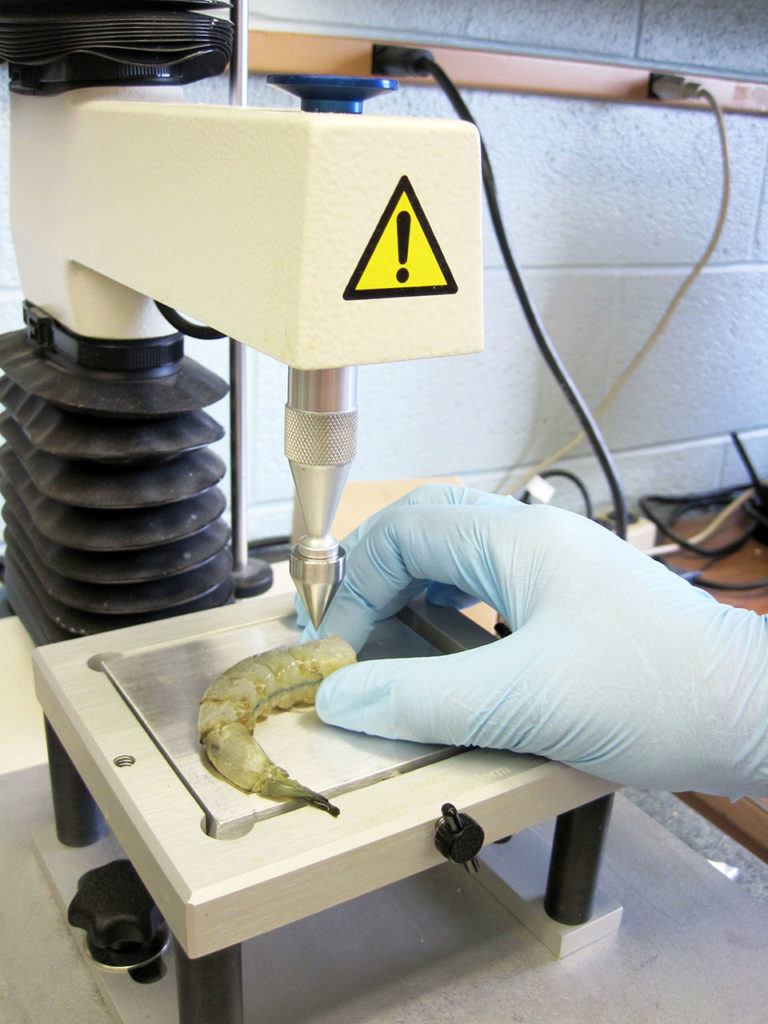

Study finds texture quality of head-on, headless shrimp similar after cold storage

Mushiness of shrimp tails is often associated with head-on shrimp. Results from the authors’ study, however, indicated that texture values did not vary much between headless and head-on shrimp stored over a two-week period at 4 degrees-C.

Health & Welfare

Antibiotic-resistant bacteria, part 2

The development of antimicrobial resistance genes in human pathogens as a consequence of exposure to antibiotics in aquaculture is widely documented. Reports implicate foodborne antibacterial-resistant pathogenic bacteria in human disease.

Intelligence

Culture of giant freshwater prawns in China

Farming of giant freshwater prawns is very popular in China. The Yangtze River Delta region produces more than 60 percent of the country's output. Production increases have resulted from a novel system that involves greenhouses that allow ponds to be stocked ahead by two months.