In a trial, radial-flow settler provided consistent removal of suspended solids

If not effectively removed from recirculating aquaculture systems, fresh fecal matter and waste feed can degrade fish health and biofilter performance, and increase the oxygen demand of the system. Increased plugging within the aeration columns, screens and spray orifices can ultimately result in system failure.

Many of the newer recirculating systems used for salmonid production in North America use dual-drain culture tanks to rapidly fractionate and flush settleable solids from the tanks to solids capture units located immediately downstream. Solids are removed from the culture tanks’ bottom drain flows using relatively small settling units.

In many of these cold-water recirculating systems, the supernatant from the settling devices and the majority of flow exiting the culture tanks’ elevated drains are combined and passed through a microscreen drum filter for additional solids removal.

Settling study

A recent study at The Conservation Fund Freshwater Institute in Shepherdstown, West Virginia, USA, evaluated the performance of two types of settling devices – a swirl separator and radial-flow settler – at removing solids concentrated within the bottom drain flow exiting circular dual-drain culture tanks. The work was supported by grants from the Agricultural Research Service, United States Department of Agriculture.

Swirl separators

Swirl separators of 1- to 2-meter diameter have been used for over a decade to trap settleable solids concentrated within tanks’ bottom drain flows. Water injected tangentially into a swirl separator at the outer radius of a conical tank causes the water to spin around the tank’s center axis. The primary rotation inside the tank creates a secondary radial flow toward the center of the conical tank that improves solids capture (Fig. 1). However, removal of aquaculture solids across a swirl separator is mainly gravity-driven and dependent on the surface-loading rate of the vessel and the settling velocity of the particles.

Swirl separators have traditionally been used to treat surface water runoff or wastewater flows that contain particles of high specific gravity, especially sand and grit, which would have correspondingly rapid settling velocities. Waste feed and fecal matter, however, can have specific gravity that is only slightly greater than water and relatively slow settling velocities.

Radial-flow settling units

Radial-flow settling units, also called circular center-feed sedimentation basins, are the most common settling tank design used in municipal wastewater treatment plants. They are often applied to settle the relatively low-specific-gravity and slow-settling microbiological solids produced during secondary wastewater treatment.

Radial-flow settlers are only similar to swirl separators in that they are both cylindrical settling tanks with effluent launders located around the top perimeter of the vessels. Both types of settling units can incorporate cone bottoms that help concentrate the captured biosolids flushed through the base of the cones.

Flow hydraulics

Radial-flow settlers have completely different flow hydraulics from swirl separators. A radial-flow settler introduces water into the center of the vessel inside a “turbulence-damping” cylinder. The injected water flows outward in the vessel’s radial direction to the overflow collection launder that surrounds the perimeter of the settler.

Radial flow from the center of the tank produces a progressively lower water velocity along the settling path as the water approaches the effluent weir surrounding the perimeter of the tank. In addition, the circumference of the circular vessels produces a substantial outlet weir length, which provides a relatively low weir loading rate.

The design of the flow injection point within the center of radial-flow settlers is critical to dampen the turbulence created by the flow injection. Wastewater treatment system text books recommend that the turbulence-damping cylinder at the center of the settling tank should be designed with at least 25 percent of the tank diameter and located well above the maximum depth of sludge to minimize resuspension of the captured solids.

Study results

In the West Virginia study, solids removal across a swirl separator, radial-flow settler, and microscreen drum filter was evaluated in a fully recirculating system with a 150-cubic-meter Cornell-type dual-drain tank during the production of Arctic char and rainbow trout.

Recirculating water flowed through the culture tank at 4,500 to 4,800 liters per minute. Approximately 7-8 percent of the recirculating water was discharged from the culture tank’s bottom-center drain through an external stand pipe to the settling tank. The remaining recirculating water exited through the side wall drain. A surface-loading rate of 0.0031 cubic meters per second per square meter settling area was applied to both settling tank designs.

TSS removal

The swirl separator and radial-flow settler were evaluated over a range of feeding rates to evaluate the relationship between inlet total suspended solids (TSS) concentration and TSS removal efficiency. A highly significant difference was observed in mean TSS removal across the swirl separator and radial-flow settler: 37.1 ± 3.3 percent and 77.9 ± 1.6 percent, respectively. Also, the radial-flow settler provided more consistent TSS removal over a broad range of inlet concentrations.

The swirl separator removed approximately 23 percent of the total mass of TSS from the recirculating system. The radial-flow settler, however, removed approximately 48 percent of the TSS mass daily. A microscreen drum filter removed 40 to 45 percent of the daily TSS mass when using either settling device.

In either case, these results indicated that treatment of the entire recirculating flow across a microscreen drum filter was critical for removing TSS from the recirculating system and preventing TSS accumulation. Total suspended solids concentrations of approximately 3 to 5 milligrams per liter were maintained in the salmonid recirculating system during this study, even at sustained daily feed rates as high as 123 kilograms per day.

Note: This article is a summary of a 2005 article by the authors that appeared in Aquacultural Engineering.

(Editor’s Note: This article was originally published in the June 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

John Davidson

Research Associate

Conservation Fund’s Freshwater Institute

1098 Turner Road

Shepherdstown, West Virginia 25443 USA -

Steven T. Summerfelt, Ph.D.

Director, Aquaculture Systems Research

Conservation Fund’s Freshwater Institute

1098 Turner Road

Shepherdstown, West Virginia 25443 USA[103,114,111,46,101,116,117,116,105,116,115,110,105,114,101,116,97,119,104,115,101,114,102,64,116,108,101,102,114,101,109,109,117,115,46,115]

Related Posts

Responsibility

Biofloc reduces feed, filtration costs in recirculating shrimp nursery system

Trials with recirculating shrimp nursery systems in India supported the use of biofloc. To control ammonia is a way to reduce filtration costs.

Health & Welfare

Biomass density affects bass production

The production period for largemouth bass in ponds hampers the economic feasibility of pond culture in the United States. A study demonstrated that bass fingerlings could be raised at high densities in a semi-closed recirculating system without serious mortality, size variability or growth retardation.

Responsibility

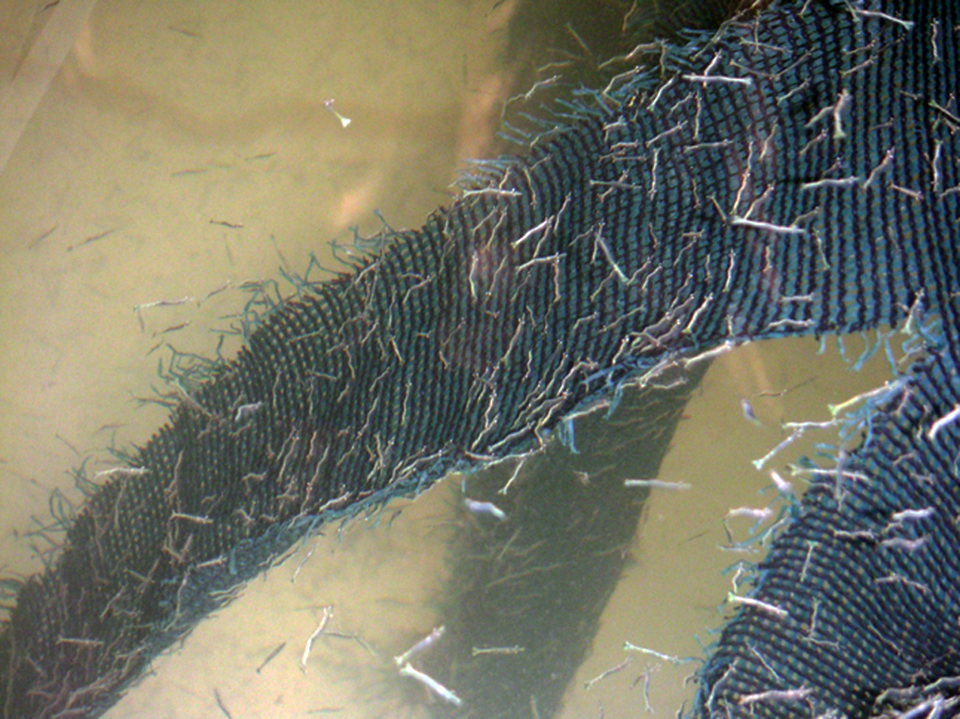

Geotextile bag, flocculant technology capture RAS waste

Geotextile bags used in combination with polymer flocculant aid chemicals can provide effective primary treatment of recirculating aquaculture system effluent. Much of the suspended solids that carry the majority of the organic load within the effluent can be captured by these systems.

Health & Welfare

Rainbow trout attain good growth, health in tank-based recirculating systems

Circular tank-based recirculating aquaculture systems can be used to effectively culture rainbow trout and other salmonids in a bio-secure and environmentally friendly manner that imposes a much lower water and wastewater footprint than traditional flow-through culture technologies.