Statement of the problem

Conventional grow-out farming practices for marine shrimp dictate that animals be initially fed on nutritionally complete diets or aquafeeds containing high dietary nutrient levels at high dietary feeding rates, and that dietary nutrient levels and feeding rates be progressively reduced thereafter until harvest. Although such dietary feeding practices may apply to the culture of any aquatic species (including shrimp) reared under intensive clear-water culture conditions, this is not the case under most practical farming conditions for marine shrimp, where animals may also derive a substantial portion of their dietary nutrient needs from the pond benthos or water column. The practical upshot of the above is over-formulation, over-feeding, poor feed conversion efficiency, unnecessary feed wastage, and last but not least economic loss to the farmer.

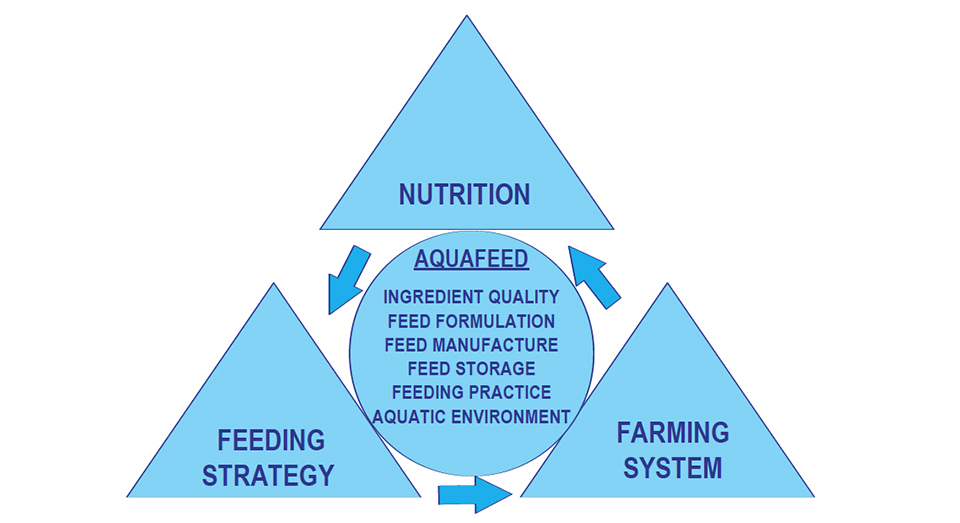

It is hoped that this column will help to dispel some of the myths and untruths surrounding the critical field of aquatic feeds and feeding in aquaculture. In particular, the column aims to assist both feed ingredient processors, feed manufacturer, and farmers alike through the development and dissemination of technical guidelines for the improved formulation, manufacture and on-farm management of aquatic feeds. Particular emphasis will be placed on the development of a more holistic or systems approach to aquatic nutrition and health management, and the need to develop and better tailor new second generation feeds and feed management practices to the intended farming system and aquatic ecosystem (see Fig. 1).

As shown in Fig. 1, the key elements of the systems approach can be divided into five equally important steps, namely 1) feed formulation and nutrient characteristics (i.e. ingredient and final nutrient levels), 2) feed physical characteristics and water stability (i.e. feed manufacturing process, feed size, shape, color, density and nutrient leaching characteristics, 3) feed storage and handling prior to feeding (including transportation), 4) feeding method and level (i.e. feed application method, feeding level, feeding frequency and timing, criteria for feed application) and 5) aquatic environment or farming system (including stocking density, natural food availability, water quality and water management).

Major hurdles and challenges currently facing shrimp feed development

- Recognition of the almost total lack of information concerning the dietary nutrient requirements of shrimp under practical outdoor farming conditions and/or under conditions of maximal attainable growth;

- Recognition of the critical role played by natural live food organisms (including microorganisms, phytoplankton, zooplankton and/or benthic organisms) within the overall nutritional budget of shrimp raised under practical outdoor farming conditions, including static-water or running-water tank or pond culture conditions;

- Recognition of the essential role played by microorganisms in maintaining the productivity, stability and health of aquatic ecosystems (including pond or tank production units), not only as sources of dietary nutrients for the farmed shrimp, but also their role in biological waste treatment by harnessing and removing potentially toxic fecal wastes and metabolites from the culture system;

- Recognition of the need to maximize dietary nutrient utilization efficiency and minimize nutrient loss and feed wastage through the development and use of improved feed formulation, feed manufacturing and on-farm feed and water management techniques; and

- Recognition of the possibility of feed ingredients and aquafeeds, including the use of natural food items, acting as vectors for the introduction and transmission of potential pathogens to the farmed shrimp, and the need to reduce this risk through the development and use of appropriate feed processing and manufacturing techniques for the destruction of potential pathogens and microbial contaminants, and/or through the selection and use of non-marine specific pathogen free (SPF) feed ingredient sources;

A cultural revolution

Although shrimp can be economically raised in a wide variety of different culture systems, one approach currently being developed at The Oceanic Institute in Hawaii is concerning the production of shrimp within experimental outdoor static-water culture systems (termed Controlled Aquatic Microcosms or CAM systems). The main characteristics of CAM systems include the use of zero water exchange or static water systems, the use of high shrimp stocking densities >50 to 150 per square meter, the use of continuous aeration and water circulation, the maintenance of green water and a healthy microbial flora, biosecurity and the use of genetically improved high health SPF animals. However, it must also be stated at the outset that CAMs are highly complex living ecosystems similar in many respects to an “aerobic rumen” or an “activated sludge” wastewater treatment system, and as such require careful management.

Research approach

Using CAMs, The Oceanic Institute has developed a research program to specifically address defining the interaction between nutrition of shrimp provided by formulated feeds and that provided by the microbial component of green water. This project is being funded through the Agricultural Research Service (ARS) of the United States Department of Agriculture (USDA) to the Oceanic Institute (OI).

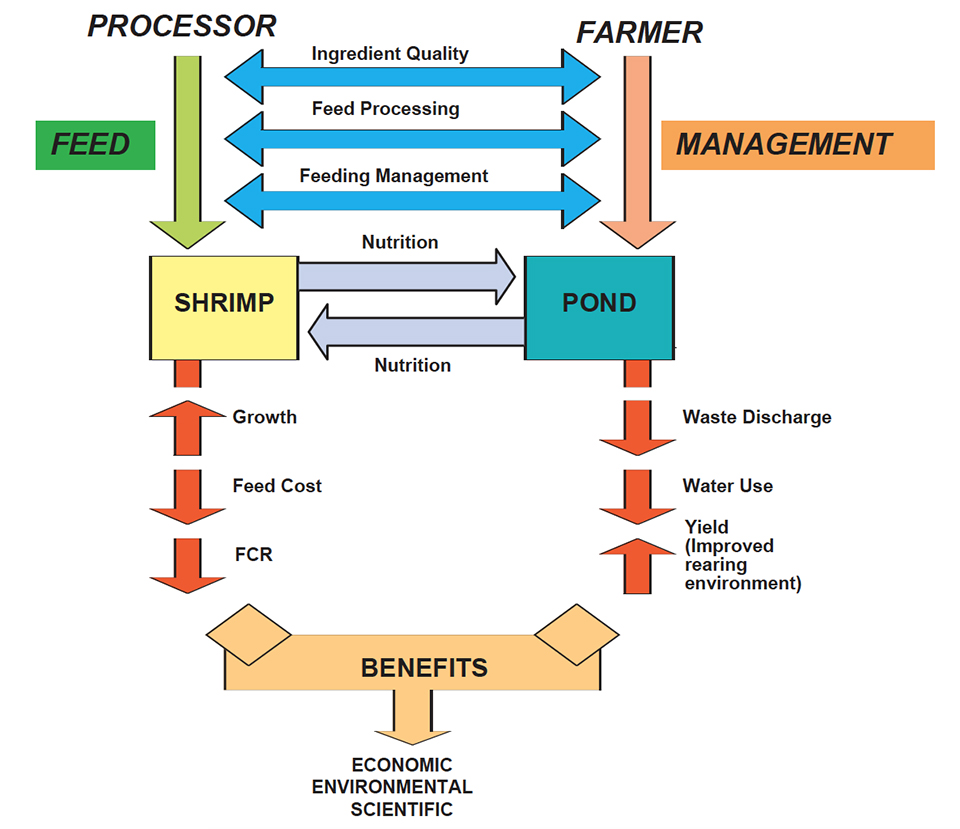

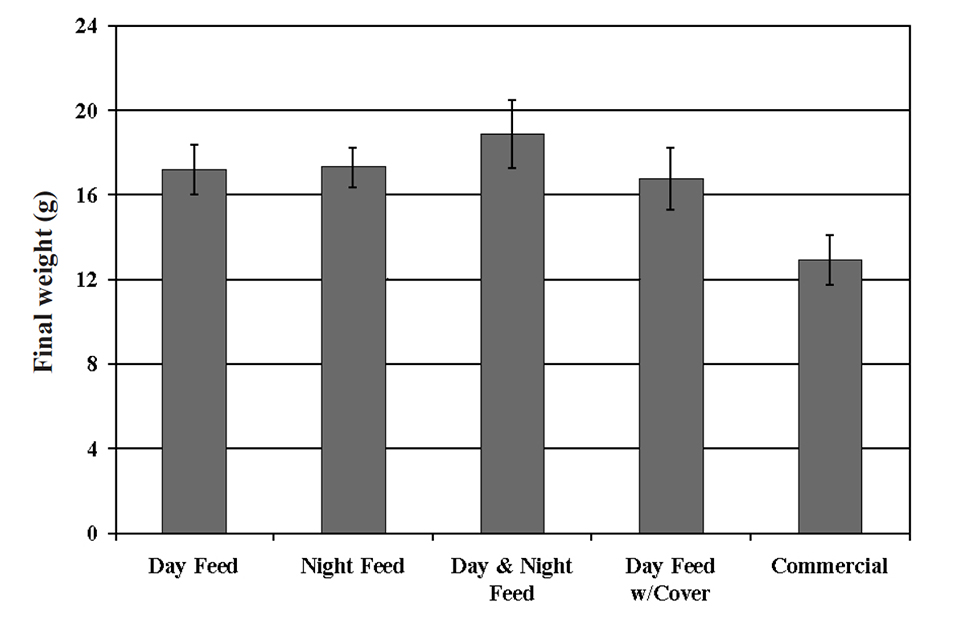

The overall goal of the five-year project is to develop second-generation feeds technology and management strategies for intensive culture of Pacific white shrimp (Litopenaeus vannamei), which optimize economic returns while minimizing deleterious effects on the environment (see Fig. 2). Although the project is still only in its second year of operation, weekly growth rates in excess of 3g per week (FCR 1.3) have been achieved this summer with shrimp stocked within CAM systems at densities of 50 animals per square meter and fed a 35 percent crude protein ration over a 24-hour feeding cycle; animals on the best treatments have grown from 1.6 grams to 15.8 grams in only six weeks (the trial is still in progress). Clearly the road is still open for improvements to be made so as to ensure the continued growth and sustainable development of the shrimp farming community, including the shrimp feed manufacturing sector, into the next millennium.

(Editor’s Note: This article was originally published in the August/October 1999 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Dr. Albert G.J. Tacon

Aquatic Feeds and Nutrition (AQUAFAN) Program

The Oceanic Institute

Makapuu Point

Waimanalo, Hawaii 967951 USA[109,111,99,46,108,105,97,109,116,110,101,103,105,108,101,116,64,110,111,99,97,116,97]

Tagged With

Related Posts

Aquafeeds

Antinutritional factors limit use of plant feedstuffs

Antinutritional factors within plant feedstuffs is a major factor that limits plant use at high dietary inclusion levels in aquafeeds.

Aquafeeds

Feeding strategies vary for shrimp producers

Shrimp are farmed globally in a wide range of production systems and fed under diverse feeding strategies throughout their life cycles.

Intelligence

Food matters: A comparative analysis of fish, income and food supply

Authors analyzed the role played by fish and fishery products – from aquaculture or from wild capture fisheries – in the diets of the richest and poorest countries. Fish and fishery products have an essential function in human nutrition.

Aquafeeds

Shrimp feeds and feeding regimes in zero-exchange outdoor tanks

Feeding trials with a new shrimp feed were conducted at the Oceanic Institute with three different feeding regimes and two tank covers.