Biofloc particles composed of uneaten feed, feces, detritus and microorganisms

Superintensive, biofloc-based culture systems have controlled feed-nutrient inputs, high stocking densities, limited or no water exchange, intense aeration or oxygenation, and an accumulation of suspended biofloc particles. These systems are currently used to culture shrimp and tilapia, and there is potential to use them for other animals.

This form of culture is environmentally sustainable due to its limited water use, which reduces discharges of potential pollutants and decreases the chance of disease transmission and interaction between wild and captive stocks. Because little water is used, and Pacific white shrimp (Litopenaeus vannamei) can be cultured in low-salinity water, this technology can be implemented in arid inland areas, providing fresh marine shrimp to such locations.

Biofloc, feeds

The biofloc particles that develop in superintensive systems are composed of uneaten feed particles, feces, detritus and microorganisms such as bacteria, algae and zooplankton. Biofloc can be ingested by the culture species, thereby recycling expensive nutrients and reducing feed costs. However, an excessive concentration of particles can lead to increased biochemical oxygen demand, gill occlusion in culture animals, suppression of beneficial algal growth and promotion of potentially harmful microorganisms.

Eliminating fishmeal and fish oil from marine shrimp diets may enhance the environmental and economic sustainability of superintensive biofloc systems. The use of marine fish products in shrimp feeds may lead to over-exploitation of fisheries and potential bioaccumulation of organic contaminants. Plant-based diets could create marketing and certification opportunities, and enhance profitability because plant products are generally less expensive and have more reliable production than fish-based products.

Experimental systems

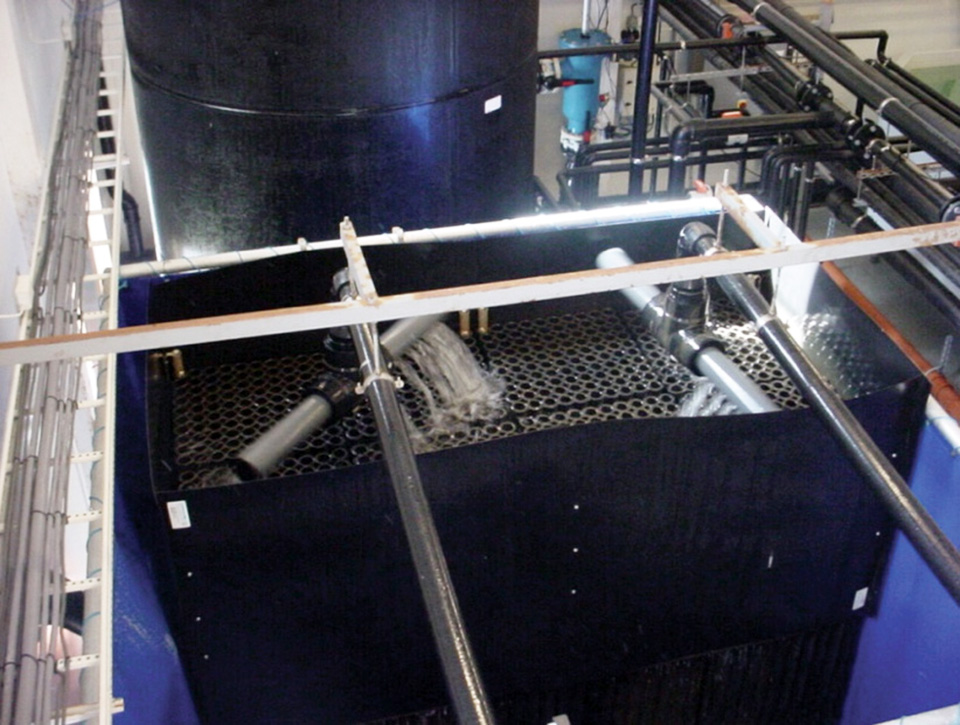

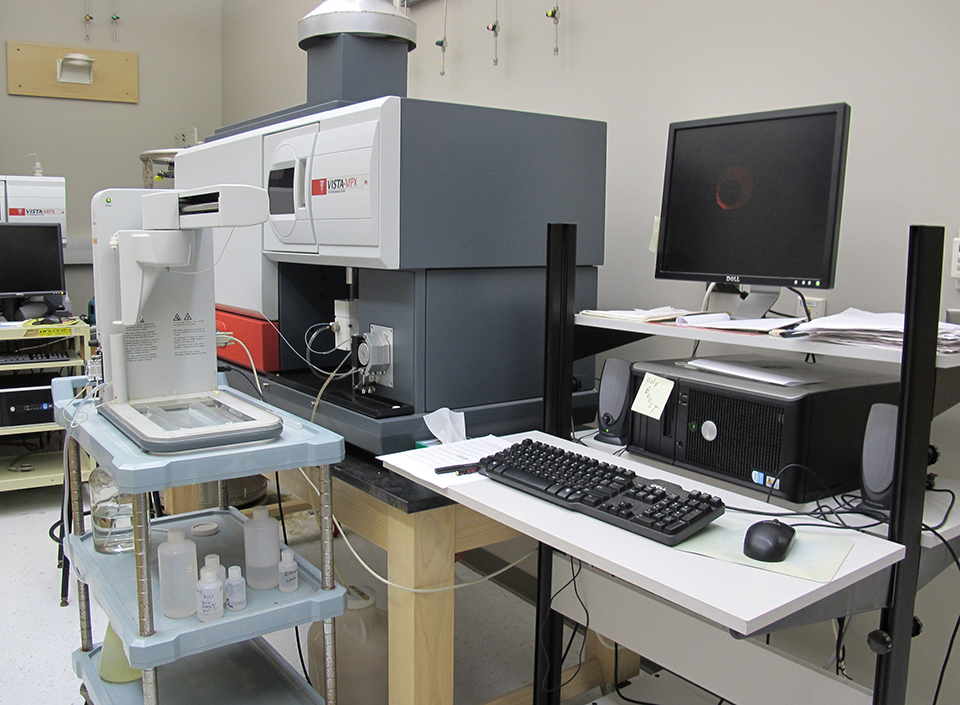

The authors recently conducted a study at the Waddell Mariculture Center in South Carolina, USA, to evaluate the effectiveness of simple, side-stream settling chambers at removing suspended particles from culture tanks and related effects on water quality and shrimp production. The study also compared a commonly used commercial fishmeal-based diet to an experimental plant-based diet.

The study was conducted using 16, 3.35-m-diameter outdoor polyethylene tanks. The tanks were filled with 6.25 cubic meters of water with a mean salinity of approximately 20 ppt and aerated using air blowers and ceramic air stones. Litopenaeus vannamei shrimp were stocked when they weighed 1.31 g at a density of 460 per cubic meter and cultured for 12 weeks.

Half of the tanks had simple, in-house-constructed settling chambers adjacent to them, and half did not. Water was airlifted to the settling chambers down a central baffle, where velocity slowed. Solids settled at the bottom of the chambers and were removed weekly. When turbidity tested periodically in the culture tanks rose above 30 nephelometric turbidity units (NTU), the chambers were operated.

For tanks with or without solids removal, half received the plant-based feed and half received the fish-based feed. This created four unique treatments (plant, plant settled, fish, fish settled), each consisting of four randomly assigned replicate tanks.

The crude protein contents of the plant- and fish-based diets were 36.4 and 35.7 percent, respectively, and total lipid levels were 10.8 and 11.0 percent, respectively. The plant-based diet – whose main ingredients were soybean meal, corn gluten meal, whole wheat and pea meal – did not contain fishmeal, fish oil or a binder. Both diets were prepared with an extrusion process.

Water quality results

Water quality parameters for temperature, dissolved oxygen, pH, salinity, ammonia-nitrogen and nitrite-nitrogen all remained within ranges acceptable for L. vannamei growth. Other than phosphate concentration, there was no significant difference in any measured water quality parameter between the two diets.

Nitrate-nitrogen concentrations were significantly decreased in the shrimp tanks with solids management, with final values of 55 mg nitrate-nitrogen/L compared to 138 mg nitrate-nitrogen/L in tanks without solids management – a difference of 60 percent.

Final phosphate concentrations were 62 percent lower in tanks with solids management than those without: 40 mg phosphate/L versus 105 mg phosphate /L, respectively. Phosphate levels were also significantly lower in tanks that received the plant diet than those with the fish diet, regardless of solids management: 58 mg phosphate/L versus 87 mg phosphate/L, respectively – a difference of 33 percent.

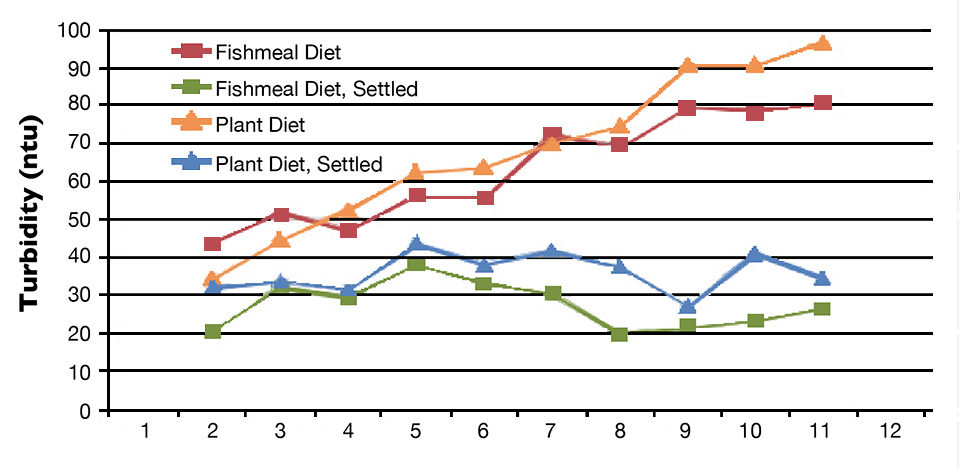

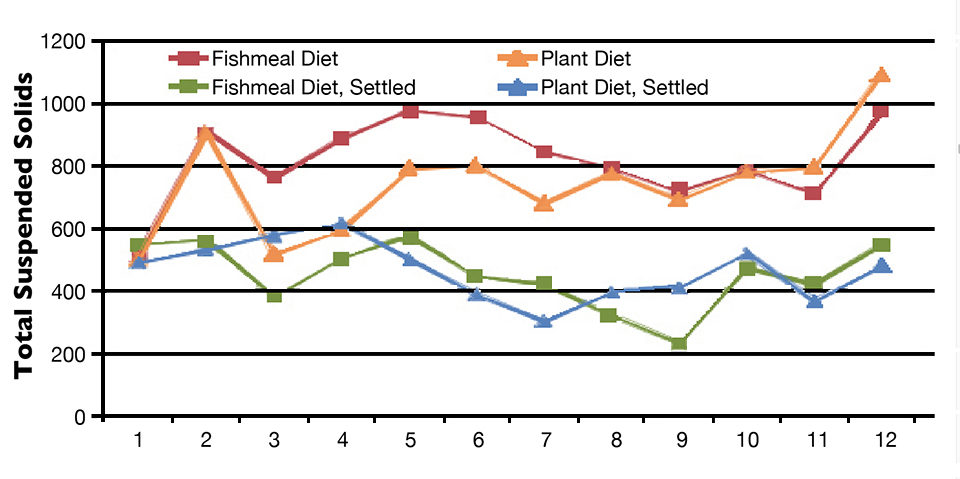

Turbidity, total suspended solids (TSS), and volatile suspended solids (VSS) were all significantly reduced by settling chambers (Figs. 1 and 2). Overall mean turbidity was 47 percent lower in tanks with solids management than those without. The mean TSS concentration in tanks with solids management was 41 percent lower than in tanks without solids management. Overall mean VSS concentration was 47 percent lower in the tanks with solids management.

Alkalinity was significantly higher in the tanks with solids management. Overall mean alkalinity was 88 mg as calcium carbonate/L in tanks with solids management and 59 mg carbonate/L in tanks without solids management – a difference of 33 percent.

Shrimp production results

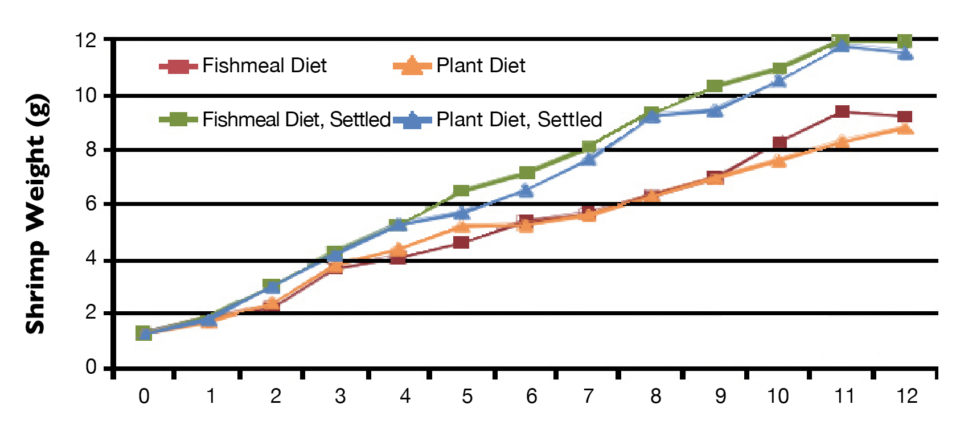

There was no significant difference in any shrimp production parameter measured between the two diets.

Overall mean survival was 71 percent in the experiment with no significant difference in shrimp survival among the treatments. The final mean feed-conversion ratio for treatments with solids management was significantly lower than for those without: 2.05 versus 2.82, respectively. At 3.04 kg per cubic meter, the final mean biomass production was 41 percent greater in treatments with solids management than those without solids management (2.16 kg per cubic meter).

Overall mean shrimp growth rate (Fig. 3) was 0.88 grams/week in treatments with solids management versus 0.63 grams/week in treatments without solids management, indicating that shrimp grew 40 percent faster with solids management.

Perspectives

Production values in this experiment were generally low, likely due to the susceptibility of the small, outdoor tanks to rapid physical changes, the relatively short duration of the experiment and the relatively high density of shrimp in the small tanks. However, the conclusions are clear, and based on these findings should likely be scaled up to commercial-scale production systems.

Managing solids during this study had dramatic effects on water quality and shrimp production. By targeting a turbidity value of 30 NTU, system performance was significantly improved. It is interesting to note that neither TSS nor VSS were statistically correlated with turbidity. However, overall mean concentrations of 459 mg/L TSS and 261 mg/L VSS were maintained using the simple, low-cost settling chambers.

Based on this, the authors recommend cropping to reduce TSS concentrations to approximately 460 mg/L and turbidity to about 30 NTU in superintensive biofloc systems to improve production. In large systems, it may be difficult to maintain such low TSS and turbidity values. However, at this point, it appears that removing a substantial quantity of suspended solids will improve water quality and shrimp production.

Because nitrate-nitrogen and phosphate concentrations were both significantly decreased, and alkalinity was significantly increased, it is possible that denitrification was occurring in the settling chambers. Denitrification is a highly beneficial microbial process for recirculating aquaculture systems that can convert nitrate to nitrogen gas, assimilate phosphate and generate alkalinity. Improved water quality can benefit production and allow culture water to be reused. Increased alkalinity may reduce the need for buffering compounds, thereby reducing production costs.

The trial data do not explain why cropping suspended solids improved shrimp production. Hypotheses include effects related to improved water quality, enhanced microbial composition or reduced gill fouling. Clearly, with a 41 percent increase in shrimp biomass, this is an important area for further research.

This project demonstrated that a plant-based diet can result in shrimp production equal to that of a traditional, fish-based diet in superintensive biofloc systems. The plant-based diet also resulted in less phosphate accumulation, which may be beneficial if water from these systems is to be reused for multiple culture cycles. Using a plant-based feed to culture shrimp may result in higher profitability and enhanced environmental sustainability. Shrimp cultured on vegetarian-based feeds may qualify for certification or labeling programs that add value to the end product. With increasing fishmeal prices, more attention should be paid to alternative formulations. By relying less on fish products for shrimp culture, the risks of bioaccumulation of organic contaminants and over-exploitation of marine resources are reduced.

(Editor’s Note: This article was originally published in the July/August 2010 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Andrew J. Ray, M.S.

University of Southern Mississippi

Gulf Coast Research Laboratory

703 East Beach Drive

Ocean Springs, Mississippi 39564 USA[109,111,99,46,108,105,97,109,103,64,121,97,114,106,119,101,114,100,110,97]

-

Jesus A. Venero, Ph.D.

Novus International Corp.

Bangkok, Thailand -

Craig L. Browdy, Ph.D.

Novus International Corp.

Charleston, South Carolina, USA -

John W. Leffler, Ph.D.

Marine Resources Research Institute

South Carolina Department of Natural Resources

Charleston, South Carolina, USA

Tagged With

Related Posts

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Responsibility

Accuracy of custom water analyses varies

The reliability of trace element analyses reported by custom laboratories cannot be checked by simple techniques, and results may not always be accurate. One should check the reliability of major ion analyses by determining the charge balance and comparing the measured total ion concentration with the total ion concentration estimated from conductivity.

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.