There is no correlation between high shear and water stability

Extruders are more efficient than pellet presses in cooking feed ingredients through mechanical energy dissipation. The degree of cook achieved in extruders is also higher than that achieved by pellet presses. However, if too much mechanical energy is used in an extruder, the resulting pellets can have poor water stability.

Pelleting systems

Shrimp aquafeeds are traditionally manufactured using pelleting systems with preconditioners with long residence time. Preconditioners precook the starch portion of the feed to improve its binding ability and produce a feed with high water stability. But the process of pelleting at moisture levels close to 17 percent is more an art than a science.

It requires highly experienced operators, and in most cases, the process cannot be maintained at sustainable rates for more than several hours without a stoppage. At the same time, the use of a postconditioner has become a requirement to increase the degree of cook and improve the water stability of the feed. In the pelleting process, most of the cooking is due to the shear produced on the surface of the pellet as the meal is formed and passed through a die, and not the steam added in the preconditioner.

High shear, pellet hydrostability

In the feed industry, there is a general understanding that a higher degree of cook means water stability will also be higher. If this is so, then why has the extrusion process not become the preferred method of production of high-quality shrimp feeds? Extruders produce a higher degree of cook because the meal is preconditioned at moistures over 20 percent, and the mechanical energy shears the product, raising its temperature and pressure (cook) higher than pelleting mills. Higher starch gelatinization, however, does not necessarily mean higher binding capacity or higher water stability.

So-called dry extruders produce high shear and a high degree of starch gelatinization (high cook), but very poor water stability. The same is true for high-shear expanders used to cook by shearing the meal, which was immediately pelletized. Therefore, there is no correlation between high shear and water stability.

Starch and cooking

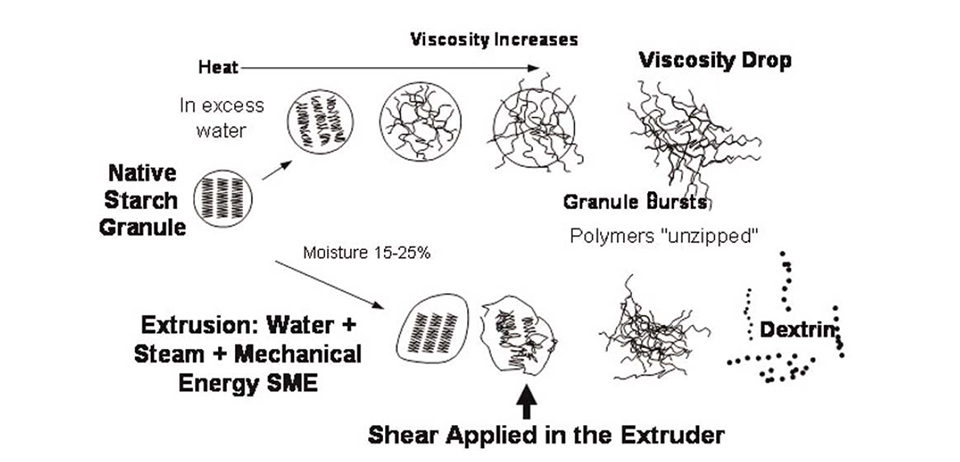

To better understand why a high degree of cook does not necessarily mean high water stability, it is first important to understand starch and how it is cooked. Starch is a biopolymer made of glucose units, which in its native state is arranged in a tight structure or granule. As a granule of starch is exposed to moisture and temperature, it starts to swell. As more energy is applied, the starch starts to break down.

In the pelleting process, starch granules may swell in the preconditioner, but not rupture. In contrast, in extrusion, the swelling started in the preconditioner is also accompanied by the mechanical energy input produced by the screws, the particles rubbing against each other, and particles rubbing against the walls of the barrel. This additional energy causes the starch granules to rupture, followed by a decrease in viscosity as the granules rupture further by the continued mechanical energy input.

As the starch or mix is worked more, it starts behaving like a fluid known in extrusion terms as “melt.” The starch is then given the term of biopolymer, as it behaves like a plastic or polymer.

With more energy, the starch breaks down into even smaller fractions of glucose units called dextrins (Fig. 1).

Changing physical properties

At the different stages of energy input, the starch changes its physical properties, and most importantly, its water stability. The protein fraction in shrimp feeds also undergoes changes due to mechanical energy input. The proteins are sheared and cooked, and interact with the starch and fiber to form a matrix.

As the molten extrudate passes through a die, it also experiences high shear forces. If the pressure drop is too high, the pellets can experience what is known as expansion. Prior to exiting the die, pressure is high in an extruder. The water is in a liquid state, but as it leaves the die, the pressure drops to atmospheric conditions, producing a change of state from liquid to gas. The vapor pressure of the gas swells the pellets.

In shrimp feeds, expansion needs to be controlled or the pellets produced will be of low density and float. The density of feed is controlled by a venting port that allows expansion but then recompresses the expanded melt – prior to exiting the die – into distinct and uniform-density pellets.

Specific mechanical energy

In most extrusion processes, high shear has an adverse effect on pellet water stability. This can be further understood by examining some relevant terms. One is specific mechanical energy (SME), a key process parameter in extrusion processing. SME is the ratio of the mechanical energy input (energy derived from the drive measured in watts) to the total mass flow rate Q. The mass flow rate is expressed in pounds per hour or kilograms per hour. SME is expressed as weight per Q, kilojoules per kilograms, or weight per kilogram.

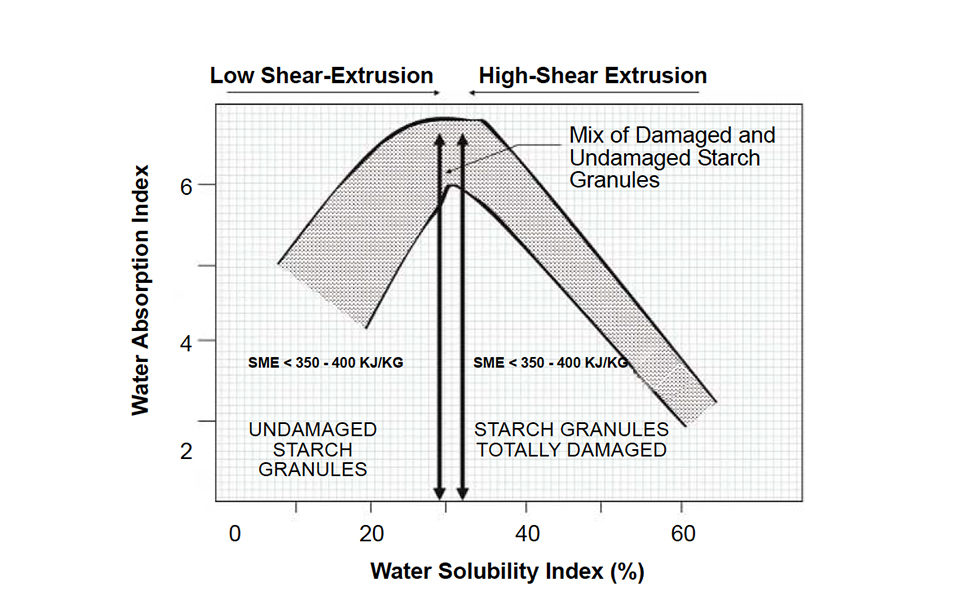

SME is used to correlate extrusion cooking conditions such as screw speed, moisture content, and screw configuration to product conversion, such as water absorption index (WAI) and water solubility index (WSI).

If screw speed increases, SME increases at a constant feed rate. Changing the screw profile directly affects SME. Screws with cut-flight or reverse elements increase the shear rate and SME. Also, for the same screw speed, reducing the feed rate increases SME.

The relationship of SME to starch damage was investigated by Smith (1992). This author demonstrated a general relationship of WAI and WSI as a function of structural changes caused to starch subjected to various degrees of mechanical energy. The main parameters studied were screw configuration, moisture content, and barrel temperature. Changes in these parameters caused the SME to vary 180-750 kilojoules per kilograms.

The data from this study also showed that the amount of swollen starch granules increased with increasing SME, but the starch granules remained undamaged below 350 kilojoules per kilograms. WAI increased as SME increased at 180-350 kilograms per kilojoules due to an increasing proportion of gelatinized starch granules. Similarly, the starch solubility in water increased with increasing SME due to the molecular degradation of the starch.

As stated earlier, the more mechanical energy is added, the higher the starch degradation and thus water solubility. In Smith’s study, as SME increased 500 to 750 kilojoules per kilograms, the starch granules were totally damaged, resulting in a decrease of the WAI and increase in WSI.

Hydrostable, extruded feeds

This last statement is important as it relates to the water stability of shrimp feeds. The goal is to produce shrimp feeds that can absorb water and become soft and pliable, but not break down when submerged. In reality, shrimp can eat softer pellets better hard ones. When feeding, they ball up pellets and consume them slowly. If pellets are too hard, shrimp simply reject them, and the wasted feed becomes potentially polluting organic matter in the pond.

Extruders that work in the high shear region have high SMEs, and most likely produce pellets of poor water stability due to the high starch degradation that causing them to have low WAI but high WSI. The model reported by Smith is presented in Fig. 2.

In the region of SME below 300 to 400 kilojoules per kilograms, WSI increases. However, as SME increases to 500 to 550 kilojoules per kilograms, WSI decreases, while WSI starts increasing. The latter confirms that starch exposed to high shear or SME is degraded to the point that it becomes very soluble in water.

Is it then possible to produce a pellet of high water stability by controlling the SME using a standard shrimp formula with no artificial binder? The answer is yes, it can be done, because new-generation extruders are equipped with state-of-the art SME controls that permit the adjustment of SME, where WAI is high enough to produce pellets that are soft and still very hydrostable.

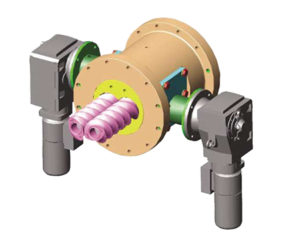

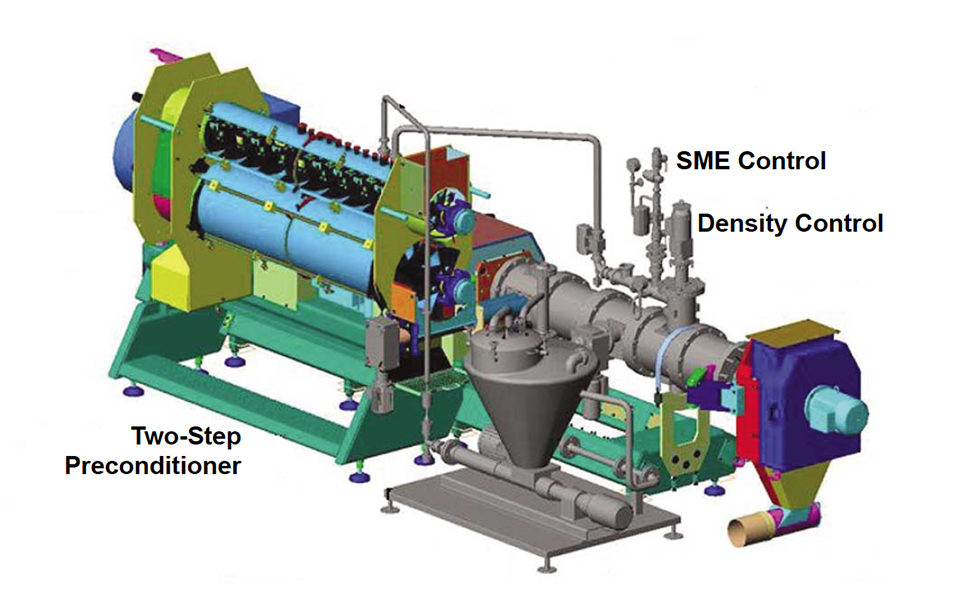

One such extruder is shown in Fig. 3. It is equipped with both an SME control valve and a density control unit in the last section of the barrel prior to the die, which facilitates the control of pellet density. The extruder is also equipped with a double-pass conditioner that includes a high mixing zone as well as a retention zone (Fig. 4).

(Editor’s Note: This article was originally published in the June 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Eugenio Bortone, Ph.D., PAS, Dpl. ACAN

1521 Country Club Drive

Red Bay, Alabama 35582 USA[109,111,99,46,108,111,97,64,101,110,111,116,114,111,98,114,100]

Tagged With

Related Posts

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

Least-cost formulation software in shrimp aquafeed production

The use of properly and efficiently formulated feeds using least-cost formulation software is an important determinant of a successful crop.

Aquafeeds

Shrimp feeds depend on proper ingredient grinding

The proper feed particle sizes of aquafeed ingredients are established by the nutritional requirements of the species targeted and by the feed manufacturing process used. For proper ingredient particle sizes, various characteristics are very important, including particle size distribution and pellet density.