Use SPC as a partial replacement only when it is cost effective to do so

Martec Industries is one of the largest fish-processing companies operating in Central America and the first one to commercially farm raise spotted rose snappers from egg to market. The company has been working in partnership with the United States Soybean Export Council to determine the best levels of replacement of fishmeal and fish oil with alternative sources for this species of snapper. The efforts are aimed at improving the ecological and economical efficiencies of the Martec operations.

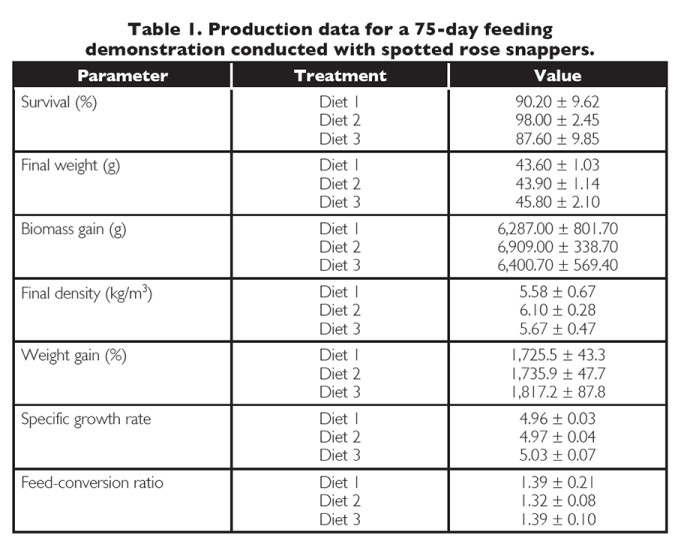

A commercial feeding demonstration was set up to evaluate the partial replacement of fishmeal in a diet for the spotted rose snapper with a soy protein concentrate (SPC) product containing 55.37 percent protein, low soy antinutritional factor content and low trypsin inhibitor activity.

Study setup

The 75-day demonstration was conducted at the Martec experimental cage farm station located near Isla Cedro at Paquera, Puntarenas Province, Costa Rica. The facility is used primarily for broodstock development and experimental studies related to nutrition and production technologies for growout stages.

Three diets were tested in the feeding demonstration. Diet 1, an SPC-based feed, was formulated to contain 50 percent crude protein and 13 percent fat with a total inclusion level up to 26.4 percent. It was nutritionally equivalent to a commercial fishmeal-based diet manufactured locally (diet 2) and a commercial diet from Japan (diet 3).

The feeding demonstration was conducted in 12, 1.2-m3 experimental cage units placed inside the farm’s two broodstock cages in the prevailing water current to maximize water exchange.

Spotted rose snappers produced by Martec’s hatchery at Rancho Chico in Playa Bejuco, Nandayure, Guanacaste Province and weighing about 2.39 g each were stocked at a density of 170 fish/cage, which was equivalent to a biomass of 0.34 kg/m3.

Nets from each experimental cage were cleaned every 10 to 12 days. Twenty fish were sampled from each experimental unit every two weeks. Individual fish weights were determined during each sampling.

Results

Feeding was ad libitum with a target of four daily feedings, but climatic conditions affected feeding. It was found that 60 percent of the time, fish fed 4 times/day. About 17 percent of the time, fish fed three times daily; 11 percent of the time, fish were fed once or twice daily; and 12 percent of the time, the snappers went without food. Water quality parameters during the feeding demonstration were very stable, with an average temperature of 27.6 ± 0.45° C and dissolved-oxygen concentration of 5.38 ± 0.94 mg/L.

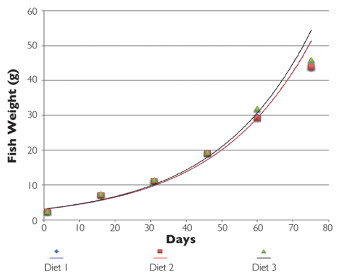

The fish that received diet 1 grew to a final average weight of 43.63 g at harvest, while fish fed diet 2 reached an average weight of 43.88 g. Fish fed diet 3 reached an average weight of 45.82 g (Table 1, Figure 1).

Fish survival was 90.2 percent for snappers fed diet 1, 98.0 percent for fish given diet 2 and 87.6 percent for fish fed diet 3. Similarly, other variables were also not significantly different among the dietary treatments (Table 1).

Final biomass per cage unit averaged 5.58 kg/m3 for the replicates fed the SPC-based diet and 5.67 kg/m3 for fish in the diet 3 treatment. For fish in units fed diet 2, biomass reached 6.10 kg/m3. Biomass gain ranged from 6.30 to 6.90 kg during the demonstration period.

With an average value of 1,817.2 percent, weight gain was highest for the spotted rose snappers fed diet 3, followed by diet 2 fish at 1,735.9 percent and diet 1 fish at 1,725.5 percent. Similarly, specific daily growth was the highest for fish fed diet 3, followed by snappers given diet 2 and diet 1. Feed-conversion ratios (FCRs) were lowest for fish fed diet 2, with an average FCR of 1.32 ± 0.08. Fish fed diet 1 and diet 3 had similar FCR values of about 1.39.

Perspectives

The analysis of the production variables obtained at the end of this feeding demonstration indicated no significant difference among the three feed treatments. Results supported the use of SPC as a partial replacement for fishmeal in diets for spotted rose snappers when it is cost effective to do so.

Research performed in 2012 by Yessica Silva-Carrillo and co-authors found that regular soybean meal can substitute for up to 20 percent of the fishmeal used in spotted rose snapper diets, representing approximately 10.5 percent soybean meal inclusion. In this feeding demonstration, SPC inclusion of 26.4 percent yielded snapper performance similar to that of fish that received fishmeal-based diets. Hence, both soybean meal and soy protein concentrate can serve as potential replacements for fishmeal without affecting growth performance.

Availability and the cost of fishmeal in the future are two conditions that might shift the cost of the SPC experimental diet compared to the commercial diets. Hence, continued development of diets based on SPC and soybean meal can be considered a key aspect for an environmentally and economically sustainable aquaculture industry.

Authors

-

Herbert E. Quintero, Ph.D.

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff, Arkansas 71601 USA[109,111,99,46,108,105,97,109,103,64,116,114,101,98,114,101,104,102,113]

-

Michael C. Cremer, Ph.D.

-

Jairo Amezquita

-

Francisco de la Torre, DVM

United States Soybean Export Council

Guadalajara, Jalisco, Mexico -

Thiago Soligo

Martec Industries S.A.

Quepos, Costa Rica

Tagged With

Related Posts

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.

Intelligence

Adding flavor complexity to farmed barramundi

Organoleptic attributes such as flavor and aroma are among the most important factors that influence consumer acceptability and demand for fish products. Consumers have identified farmed fish as less complex and lacking “sealike” or “sea-fresh” flavors and aromas.

Innovation & Investment

Artemia, the ‘magic powder’ fueling a multi-billion-dollar industry

Artemia, microscopic brine shrimp used as feed in hatcheries, are the unsung heroes of aquaculture. Experts say artemia is still inspiring innovation more than 50 years after initial commercialization. These creatures are much more than Sea-Monkeys.

Intelligence

Are omega-3s in farmed jade perch as high as believed?

Farmed jade perch – similar to other cultured fish species – is only rich in omega-3 fatty acids if its diet consists of these nutrients in high amounts. How does it compare to the wild fish?