Combining plant-based diets and advanced feeding technologies can provide unique advantages to commercial producers

Shrimp are one of the most valuable traded seafood items, and the Pacific white shrimp (Litopenaeus vannamei) is the preferred shrimp species for aquaculture due to its capacity to grow in a wide range of culture environments. Feed is the most important variable cost and source of nutrients, and consequent biological waste in semi-intensive and intensive aquaculture systems. Currently available shrimp feeds are generally adequate and there is considerable knowledge and numerous research and commercial demonstrations of soy-based feeds with limited or no animal protein. Such feed would be considered much less costly and a more sustainable alternative to fishmeal-based feeds.

Although improved feeds are available to enhance sustainability, they must be matched with optimized feed delivery. Following the footsteps of other subsectors of agriculture, the aquaculture industry has been moving towards increasingly automated feeding systems for a wide variety of tasks. Automatic feeding systems have achieved a pivotal role in aquaculture intensification for fish and these technologies are now being applied to shrimp production.

Shrimp are grazers with limited capacity to store feed in their digestive tract, which results in slower continued ingestion of small quantities of feed. Hence, multiple studies have shown enhanced growth performance of shrimp with multiple feedings through the day. However, multiple daily feeding applications can be very labor-intensive and economically impracticable in many regions.

To further complicate management, unlike in fish systems where there is often direct observation of feeding behavior, traditional feed management techniques for shrimp are indirect and after the fact. Feed inputs are often estimated through feed tables, observation from feeding trays, visual confirmation of the gut, or a combination of various indirect measures. Such techniques are useful, but they are not real-time. As a response to the necessity of the shrimp farming industry to improve its feed management protocols, automated technologies have been developed and are now being employed by numerous farmers worldwide.

A unique feature of shrimp is that they externally masticate their feed. This particular feeding activity is acoustically active producing a distinctive clicking noise as food is shredded and has led to the development of an acoustic demand-feeding system which has been proven to be a reliable tool in shrimp farming. Previous works by Jescovitch et al. (2018), Ullman et al. (2018) and Ullman et al. (2019) have shown improvements in growth performance by application of acoustic demand-feeding system in comparison to two hand-feeding per day or timer based feeders which deliver feed multiple times per day.

Over the last two years at our research production facility we have transitioned from two feedings per day running a 120-day production cycle to the use of automated feeding systems running a 90-day production cycle. Despite reducing the production cycle by 30 days we are producing a larger biomass and shrimp of larger size. This is accomplished as the automated feeding systems allow for more feeding and thus higher consumption of feed, which in turn promotes faster growth.

The present study builds off the previously mentioned research, which developed soy-optimized feeds to reduce feed costs and present a more sustainable feed, primarily based on sustainable plant-based ingredients. This feed was then used to demonstrate the use of soy-optimized production diets and to improve the efficacy of automated feeding systems for shrimp.

The objective of our work has been improving the understanding and practical functionality of automated systems, concentrating on improving timer-feeder protocols by slowly increasing feed quantities using increased frequency of scheduled meals. It has been carried out in parallel with an acoustic demand-feeding system (AQ1 Systems,Tasmania, Australia), which has allowed the validation of this technology under a practical production scenario. In addition to a practical feed demonstration using new automated technology, these data demonstrate the efficacy and performance of shrimp on soy-optimized feeds.

Study design

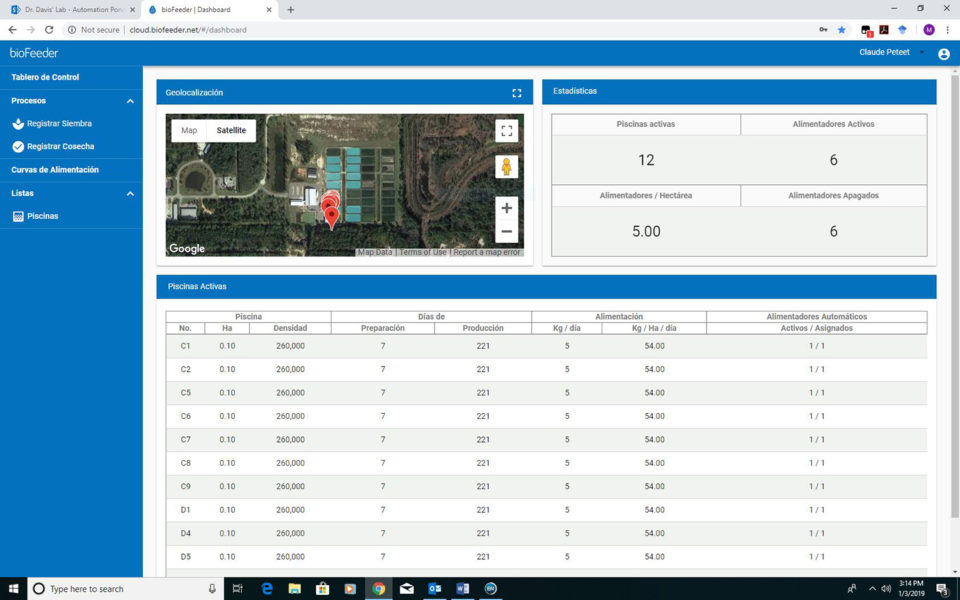

The research was performed at the Alabama Department of Conservation and Natural Resources, Claude Peteet Mariculture Center, Gulf Shores, Alabama (USA). Pacific white shrimp (L. vannamei) larvae were obtained from Shrimp Improvement Systems (Islamorada, Fla., USA), acclimated and nursed in a greenhouse system. Juvenile shrimp were then stocked into 16 outdoor, 0.1-hectare (ha) ponds at 17 shrimp per square meter in 2016, 38 shrimp per square meter in 2017 and 26 shrimp per square meter in 2018.

Feed management

All ponds were offered the same two diets: 1.5-mm commercial diet (40 percent crude protein, 9 percent crude lipids) produced by Zeigler Bros. Inc. (ZBI, Garners, Pa., USA) for the first four weeks, and 2.4-mm 35 percent protein, 8 percent lipid diet produced by ZBI was fed from the fourth week on. In 2016 and 2018 the production diet was a soy-optimized feed, and in 2017 a commercial shrimp diet, SI-35 was fed. Three treatments were evaluated each year based on a standard feeding protocol (SFP) calculated based on an expected weight gain of 1.3 grams per week, a feed conversion ratio (FCR) of 1.2, and expected population based on a 1.5 percent weekly mortality during the grow-out period.

The first year of research compared hand-feeding twice daily using the SFP, SFP +15 percent, and SFP +15 percent using a solar timer feeder (Solarfütterer, FIAP GmbH, Ursensollen, Germany) that fed six times per day between 8 a.m. to 6 p.m. and the fourth treatment was self-managed using the AQ1 acoustic feeding system, which allowed feeding from 7 a.m. to 1 p.m. The second year compared hand feeding SFP, two solar timer feeder treatments feeding SFP +15 percent and SFP +30 percent, as well as the AQ1 acoustic feeding system. The present research removed the hand feeding treatment and switched to a timer feeder that allowed more than six feedings per day. The three timer treatments were SFP +30 percent, SFP + 45 percent, SFP + 60 percent and the AQ1 feeding system.

The current feeders used for SFP treatments were BioFeeder (BioFeeder SA, Guayaquil, Ecuador) timer-feeders, set to feed once every 20 minutes from 7 a.m. to 7 p.m., resulting in 36 feedings per day. The feeders were controlled remotely using the feeder’s specific web-based software that can be accessed from any computer or phone. The AQ1 feeding system fed ad libitum using a hydrophone with computer software to monitor feeding activity.

In the most recent research, in an attempt to not limit the feeding to daytime hours, the AQ1 system was also equipped with an underwater DO sensor and the system was set to only allow feeding when DO levels were above 4 mg/L. In all four ponds using the AQ1 system, the main aerator was connected to the controller to automate the aerator activity based on the DO sensor measurements. The system turned on the aerator below a DO threshold and paused the feeder until the DO was above a set level in which the aerator turned off. AQ1 treatment were non-randomly assigned to ponds due to power supply restrictions.

Sampling and water quality

Shrimp were sampled weekly through the entire production stage using a cast net (1.52 m radius and 0.96 cm mesh) to collect approximately 60 individuals per pond. Pond sampling enabled growth assessment and inspection for general health. Ponds were monitored (DO, temperature, salinity, and pH) at least three times a day, at sunrise (5:00 to 5:30 a.m.), afternoon (2:00 to 2:30 p.m.) and sunset (7 to 8 p.m.).For maintenance of dissolved oxygen (DO) above 3 mg/L, all ponds were supplied with one 2-HP Aire-O2 (Aire-O2, Aeration Industries International, Inc., Minneapolis, MN, USA) as a main source of mechanical aeration and one Air-O-Lator (Kansas City, MO, USA) for backup and/or supplemental aeration as needed.

Results

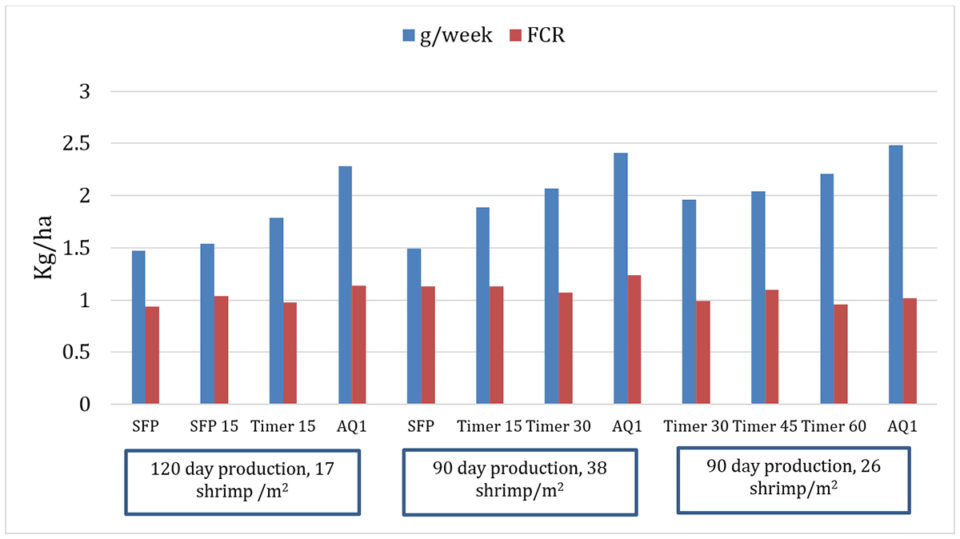

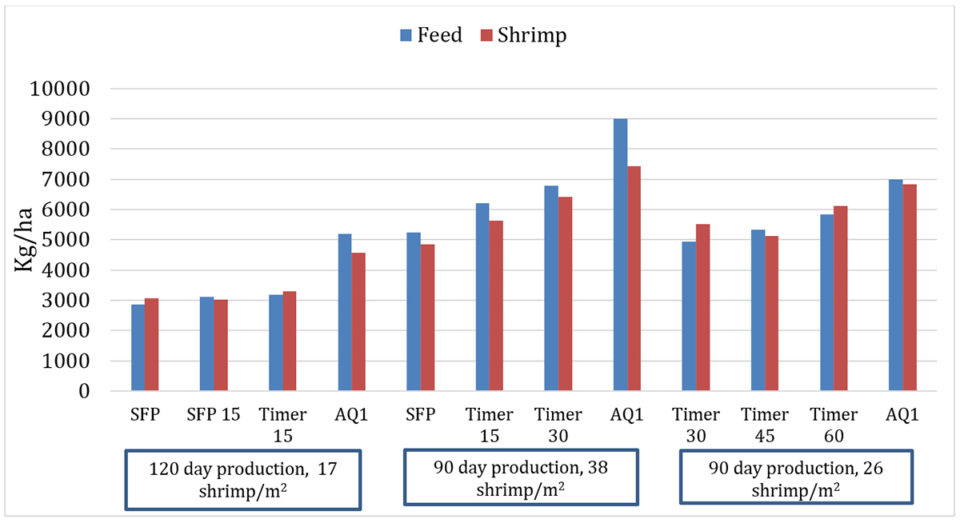

A combined summary of the past three years of research can be seen in Figs. 1 and 2. The improved growth performance from hand feeding two times per day to timer feedings is significant. By using automated feeders and increasing the feed input we were able to reduce the production cycle from 120 to 90 days. It is clear that increasing the number of feedings per day allows increases to our standard feed inputs (+30, 45 and 60 percent above SFP), which resulted in increased shrimp production.

Growth rates (grams per week) for the AQ1 system (treatment 4) were consistently the highest as it adjusted feed inputs in real time. The AQ1 treatment also had the highest yield and feed input. It is interesting to note that, although the acoustic system adjusted feed inputs based on real time inputs, there were no differences in FCR. We are conservative with our feed inputs, so even at that 160 percent level of feed inputs (SFP 60), feed was limited and the shrimp consumed all that was fed. It is likely that the shrimp also utilized natural foods present in the pond.

It is important to note the soy optimized diet used in 2016 and 2018 provided similar results to the commercial shrimp diet used in 2017. Hence, the use of automatic feeders or a feeding system with acoustic feedback resulted in good growth and production. Growth was similar across all feed inputs up to about 50 days after which the lower levels of feed input limited growth.

This provides us an opportunity to use the data to develop an improved feed management strategy based on an incremental increase in inputs. Towards this goal, we will use feed inputs and growth data to back-calculate a recommended feed input for the use of automated feeding systems providing an invaluable tool for farmers using automated feeding systems.

Perspectives

The results over three years of testing clearly demonstrated that increasing daily feedings through the use of automated feeding systems can significantly increase the production and value of L. vannamei produced in semi-intensive pond culture. Based on the use of automated feeding systems, we have seen large increases in shrimp growth rates and reductions in the number of days to a given size while maintaining excellent feed conversion. In general, automated feeding systems are a transformational technology which confer numerous advantages for shrimp culture. Our results confirm that a standard feeding protocol can be developed for automated feeding system that will support enhanced growth rates.

It is our opinion that simple automatic feeding systems will never match real time adjustments to feed inputs which respond to actual demand of the shrimp. Albeit implemented at a much higher cost, automated feedback systems appear to be a better management option for maximizing shrimp production in the shortest time.

It should be noted that the application of these technologies will increase feed input requiring adjustments in pond management and that personnel will need to be trained in proper maintenance of the feeding systems. It is also worth underlining that we were able to achieve more than acceptable growth performance while applying fishmeal-free soy-based diets, which are still looked with skepticism by some sub-sectors of the industry.

The combination of plant-based diets and advanced feeding technologies allow for a more efficient system which will provide a unique set of advantages if adopted by commercial producers.

References available from last author.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Joao Torres Reis

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn AL 36849 USA[117,100,101,46,110,114,117,98,117,97,46,108,105,97,109,114,101,103,105,116,64,50,54,48,48,116,122,106]

-

Anneleen Swanepoel, M.S.

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn AL 36849 USA -

Romi Novriadi, Ph.D

Directorate General of Aquaculture

Ministry of Marine Affairs and Fisheries

Republic of Indonesia[100,105,46,111,99,46,111,111,104,97,121,64,108,98,98,95,105,109,111,82]

-

Melanie Rhodes, M.S.

Research Associate

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn AL 36849 USA -

Allen Davis, Ph.D.

Alumni Professor

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn AL 36849 USA[117,100,101,46,110,114,117,98,117,97,64,97,100,115,105,118,97,100]

Tagged With

Related Posts

Aquafeeds

Automated feeding systems in pond production of Pacific white shrimp

Results of this study show that automated feeding systems are significantly more efficient than hand feeding in shrimp production ponds and that increases in feed input, application of adaptive technology and training of people to maintain the feeding system must all be considered.

Aquafeeds

Demand feeding through automatic dispensing systems

Studies showed that the demand feeding system for farmed shrimp – based on multi-rations and combined with sound detection – can be used to distribute the correct dosage of aquafeed with high nutritional density.

Aquafeeds

Automatic feeding in shrimp aquaculture

Controlled by timers, automatic feeders should be placed in deeper areas of ponds and away from aerators. Overfeeding is rare during automatic feeding, and pond bottom quality is maintained through grow-out cycles.

Innovation & Investment

Eight digital technologies disrupting aquaculture

Eight digital technologies are disrupting aquaculture and having a profound impact on the way business operates – even displacing some established ones.