Aeration can eliminate need for a Venturi, air diffusers and airlifts

The combination of zero-water-exchange shrimp production and recirculating aquaculture systems has evolved into what is now commonly referred to as “biofloc” technology. Biofloc systems utilize the biochemical processes of native microorganisms to regulate nutrient cycles and their effects on shrimp performance.

One characteristic of biofloc-dominated systems is the development of microbial flocs that typically form six to seven weeks after stocking. In addition to heterotrophic and autotrophic bacteria, the bioflocs that develop in the presence of natural light also contain microalgae. The daily input of dry feed for the shrimp results in continued production of biofloc in the culture medium.

Four shrimp production studies using biofloc technology conducted at the AgriLife Research Mariculture Lab in Corpus Christi, Texas, USA, evaluated different approaches to maintain water quality.

Particulate matter control

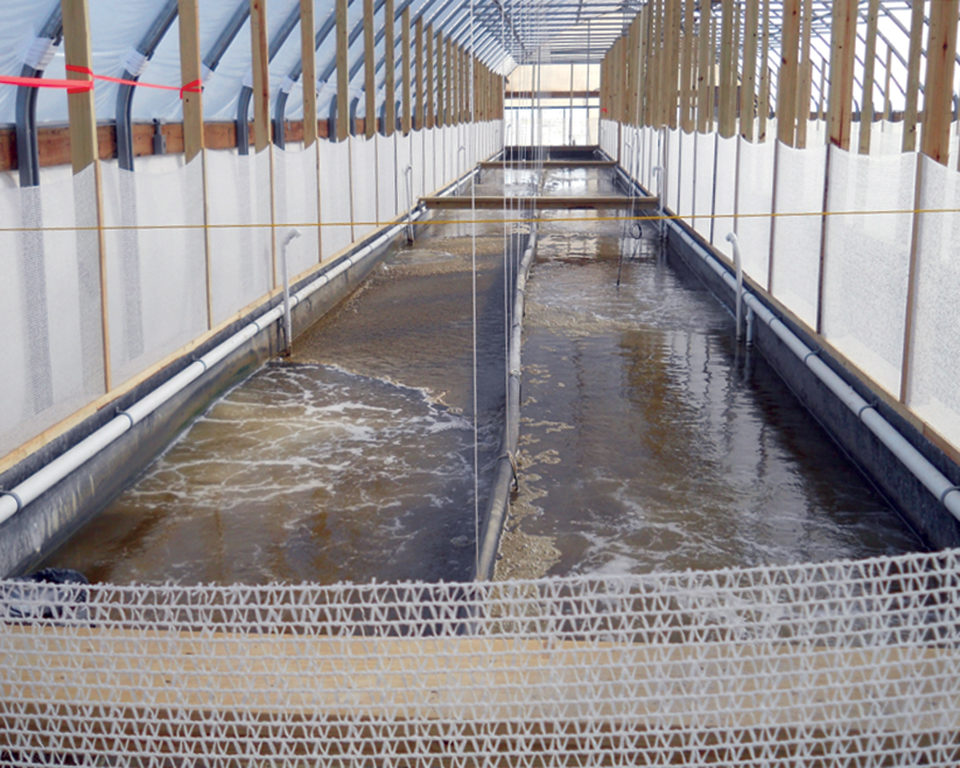

A 94-day growout study conducted in 2007 compared the effectiveness of settling tanks and foam fractionators in controlling particulate matter build-up in four 40-m3 lined, greenhouse-enclosed raceways. Each raceway was equipped with a longitudinal center partition and six banks of three 5.1-cm airlifts on both sides of the partition. In addition, each raceway had six air diffusers and a 2-hp centrifugal pump with a Venturi injector. All four raceways were filled with water previously used in a 77-day nursery study and stocked at a density of 530/m3 with juvenile Pacific white shrimp, Litopenaeus vannamei, weighing 1.25 ± 0.17 g eac

Shrimp were fed a 35 percent-crude protein commercial feed. Beginning on day 52, when the estimated shrimp biomass load was between 5 and 6 kg/m3, feed was offered in four equal portions during the day. For the remainder of the study, two-thirds of the daily ration was fed in four equal portions during the day with the rest delivered throughout the night using belt feeders to minimize adverse dissolved-oxygen fluctuations following feeding.

Daily rations were adjusted based on an assumed feed-conversion ratio of 1:1.4, weekly growth of 1.2 g and weekly mortality of 0.5 percent. The rations decreased from about 5.0 kg/raceway during the first week to 4.8 kg/raceway during the final week. Fresh water was added weekly to offset evaporative losses.

Fractionators, settling tanks

To control particulate matter, two raceways were each outfitted with a homemade foam fractionator, 3.05 m long and 30.48 cm in diameter, operated by a 3.81-cm Venturi injector and powered by a 1-hp pump. The other two raceways were each equipped with an 8.6-m3 cylindroconical settling tank with a 4.9-m3 working water volume.

The fractionators and settling tanks began operating on day 29 with targeted total suspended-solids (TSS) levels of 500 mg/L. Settling tank use was discontinued on day 79, when TSS levels dropped below 175 mg/L.

Mean water temperature, salinity, pH, and dissolved oxygen during the study period in both treatments were 29.4 degrees C, 33 ppt, 7.3 and 4.8 mg/L, respectively. The mean values for total ammonia nitrogen (TAN), nitrite nitrogen (NO2-N), nitrate nitrogen (NO3-N), carbonaceous biochemical oxygen demand (cBOD5), reactive phosphorus, TSS and volatile suspended solids (VSS) for the raceways operated with fractionators and settling tanks were 0.10 vs. 0.11, 0.02 vs. 0.01, 74 vs. 120, 35 vs. 33, 17 vs. 17, 588 vs. 458 and 414 vs. 349 mg/L, respectively.

Results

Small differences were found between the raceways operated with the foam fractionators and the settling tanks in settleable solids (49 vs. 33 mL/L), turbidity (307 vs. 276 nephelometric turbidity units, NTU) and algae (75 x 104 vs. 53 x 104 cells/mL). Sodium bicarbonate was regularly added to the raceways to maintain alkalinity, but average levels varied 60-308 mg/L calcium carbonate during the trial. Efforts were made to keep TSS concentrations in the 500 mg/L range.

At 18.45 g, the average weight of the shrimp in raceways operated with settling tanks was significantly higher than the 17.35 g for those in the raceways with fractionators. No statistically significant difference was found in total yield, survival, growth or feed conversion between the two treatments (Table 1).

Samocha, Performance of juvenile Litopenaeus vannamei, Table 1

| Tank | Avg. Weight (g) | Growth (g/wk) | Survival (%) | Yield (kg/m3) | FCR | Oxygen (Lpm, days 74-94) |

|---|---|---|---|---|---|---|

| RW1-ST | 18.4 | 1.32 | 88.3 | 9.29 | 1.21 | 3.5 |

| RW2-FF | 17.4 | 1.22 | 80.5 | 8.57 | 1.40 | 3.5 |

| RW3-FF | 17.3 | 1.30 | 80.5 | 7.92 | 1.30 | 3.5 |

| RW4-ST | 18.5 | 1.23 | 80.0 | 8.63 | 1.36 | 3.5 |

From day 74 on, atmospheric air was enriched with pure oxygen at a rate of 3.5 Lpm. Until day 73 (shrimp biomass load of about 7 kg/m3), oxygen demand was met solely by the airlifts, the air diffusers and the pump-driven Venturi injectors operated with atmospheric air. This suggests that a shrimp biomass load of about 7 kg/m3 can be maintained using a pump-driven Venturi injector and atmospheric air.

Smaller fractionator

In 2009, a second growout study was conducted to determine if smaller fractionators operated on a more continuous basis could minimize the differences in final shrimp weights observed between the treatments in 2007. The 108-day study was conducted in the same four, 40-m3 raceways described for 2007. The raceways were filled with water used in a preceding 62-day nursery study and stocked with juvenile Pacific white shrimp weighing 0.99 ± 0.17 g at 450 shrimp/m3.

Mean values for water temperature, salinity, pH and dissolved oxygen were 29.3 degrees C, 30.6 ppt, 6.8 and 5.0 mg/L, respectively. The mean values for TAN, NO2-N, NO3-N, cBOD5, reactive phosphorus, TSS and VSS were 0.17 vs. 0.16, 0.35 vs. 0.30, 267 vs. 220, 25 vs. 27, 17 vs. 17, 502 vs. 434 and 236 vs. 202 mg/L for the raceways operated with foam fractionators and settling tanks, respectively.

Small differences in settleable solids (15.0 and 14.1 mL/L) and turbidity (219 and 213 NTU) were found between the raceways operated with the fractionators and settling tanks, respectively. Sodium bicarbonate was regularly added to the raceways to maintain alkalinity at 160 mg/L calcium carbonate. The average levels were 124 mg/L for the fractionator treatments and 129 mg/L in the settling tank treatments.

Fresh water was added weekly to offset evaporative losses. The settling tanks and foam fractionators were operated intermittently from day 23, targeting culture water TSS concentrations between 400 and 600 mg/L. Flow into the settling tanks was maintained at 2 to 8 Lpm.

Results

The results from this study (Table 2) showed no significant differences in final shrimp weights between the treatments, suggesting that the ability to run the smaller fractionators at a more controlled rate created an improved environment for the shrimp. Furthermore, no statistically significant difference was found in weekly growth, yield, feed conversion and water usage between treatments.

Samocha, Performance of juvenile Litopenaeus vannamei, Table 2

| Tank | Avg. Weight (g) | Growth (g/wk) | Survival (%) | Yield (kg/m3) | FCR | Oxygen (Lpm, days 101-108) |

|---|---|---|---|---|---|---|

| RW1-ST | 21.96 | 1.36 | 94.5 | 9.34 | 1.60 | 0.19 |

| RW2-FF | 22.51 | 1.35 | 96.9 | 9.51 | 1.53 | 0.36 |

| RW3-FF | 22.40 | 1.39 | 96.3 | 9.75 | 1.57 | 0.19 |

| RW4-ST | 21.81 | 1.39 | 94.5 | 9.52 | 1.57 | 0.16 |

The higher 1.4-g weekly growth assumption used in 2009 resulted in higher amounts of feed offered to the shrimp. However, yields were also higher, and oxygen supplementation was considerably less than in 2007.

Non-venturi injectors

In addition to the 2007 and 2009 trials, many previous raceway studies at Texas AgriLife utilized pump-driven Venturi systems to mix and oxygenate the culture water with additional circulation and mixing provided by airlifts and air diffusers. This system has worked well for numerous growout studies in the past, but in an effort to cut production costs by reducing oxygen supplementation and electricity usage, the authors have been testing an alternative non-Venturi injector.

Could the new injectors meet the oxygen demands of the raceway systems using atmospheric air? The injectors are currently used in several wastewater treatment facilities in the United States and require less maintenance and energy inputs than other wastewater oxygenation alternatives. This technology may be successfully transferred to biofloc systems and other types of aquaculture.

According to the manufacturer’s specifications, the injectors provide a 3:1 ratio of air to water. In contrast, the researchers’ current Venturi system provides a mixing ratio below 1:1 and requires supplementation with pure oxygen at biomass loading above 7 kg/m3.

In 2009, the authors initiated a month-long preliminary test of this technology in one 40-m3 raceway filled with 170-day-old biofloc-rich water from a previous study and stocked with 21.9-g shrimp at 403/m3. Shrimp were then raised 38 days to an average weight of 25.2 g and a final biomass of 9.59 kg/m3.

Using one 2-hp pump, the injectors were able to maintain dissolved-oxygen levels near saturation and provide adequate mixing throughout the water column, thus eliminating the need for supplemental oxygen, blowers, airlifts and diffusers.

Further testing

In 2010, further testing of this injector was conducted to evaluate its ability to maintain adequate levels of dissolved oxygen without the use of pure oxygen and keep particulate matter in suspension in a zero-exchange super-intensive system

An 87-day study was conducted in two lined super-intensive biofloc system raceways filled with a mixture of seawater and biofloc-rich water. To provide aeration, mixing and circulation, 14 non-Venturi nozzles were positioned parallel to the direction of flow along the bottom of each raceway wall. In addition, one nozzle was used to power a home-made foam fractionator for removal of particulate and dissolved organic matter. Two pumps with a total of 5 hp were used to power the 15 nozzles in each raceway.

Shrimp weighing 8.5 g were stocked at 270/m3 and fed a 35 percent-crude protein diet. Fresh water was added weekly to maintain salinity, but the raceways were maintained with no water exchange. Mean water temperature, salinity, pH and dissolved oxygen were 30 degrees C, 30.8 ppt, 7.0 and 5.8 mg/L, respectively. TAN and NO2-N remained below 0.5 mg/L throughout the study. NO3-N levels increased from 61 mg/L at stocking to about 400 mg/L at harvest.

Results

Due to declining temperatures, shrimp were harvested at a size of about 26.1 g (6.4 kg/m3) before the system reached its carrying capacity. Table 3 summarizes results. Survival was high, and shrimp growth averaged 1.4 g/week with mean final weights of 26.2 g. However, the feed-conversion ratio was unusually high (2.5:1). Future studies are planned to address this issue.

Samocha, Performance of juvenile Litopenaeus vannamei, Table 3

| Tank | Avg. Weight (g) | Growth (g/wk) | Survival (%) | Yield (kg/m3) | FCR | Oxygen Usage (Lpm) |

|---|---|---|---|---|---|---|

| RW1 | 25.68 | 1.38 | 89.5 | 6.25 | 2.56 | 0 |

| RW2 | 26.58 | 1.45 | 90.8 | 6.56 | 2.36 | 0 |

This study showed the injectors were capable of maintaining D.O. levels near saturation without oxygen supplementation or the use of belt feeders at the harvest biomass of 6.4 kg/m3. The aeration system enabled good mixing and suspension of the particulate matter in the culture medium. In addition, the injectors used for operating the foam fractionators were adequate to keep particulate matter below the targeted TSS levels.

Results suggested that this aeration system can eliminate the need for a Venturi and devices such as air diffusers and airlifts for maintaining D.O. and mixing.

(Editor’s Note: This article was originally published in the September/October 2012 print edition of the Global Aquaculture Advocate.)

Authors

-

Tzachi M. Samocha, Ph.D.

Texas AgriLife Research

AgriLife Research Mariculture Laboratory

4301 Waldron Road

Corpus Christi, Texas 78418 USA[117,100,101,46,117,109,97,116,64,97,104,99,111,109,97,115,45,116]

-

Timothy C. Morris

Texas AgriLife Research

AgriLife Research Mariculture Laboratory

4301 Waldron Road

Corpus Christi, Texas 78418 USA -

Jong Sheek Kim

West Sea Mariculture Research Center

National Fisheries Research & Development Institute

Taean, Chungnam, Republic of Korea -

Eudes S. Correia

Universidade Federal Rural de Pernambuco

Recife/P.E., Brazil -

Bob Advent

a3 All Aqua Aeration Systems

Orlando, Florida, USA

Tagged With

Related Posts

Aquafeeds

Biofloc and clear-water RAS systems: a comparison

This study compared two types of indoor, shrimp culture systems: clear-water RAS and biofloc systems. Clearwater RAS had the edge in water quality, but shrimp in the biofloc treatment had a higher feed conversion ratio.

Aquafeeds

Biofloc consumption by Pacific white shrimp postlarvae

The stable isotopes technique with δ13C and δ15N can be used to determine the relevance of different food sources to shrimp feeding during the pre-nursery phase of Litopenaeus vannamei culture. During this trial, different types of commercial feed, microalgae, Artemia sp. nauplii and bioflocs were used as food sources.

Aquafeeds

Biofloc systems viable for tilapia production

Well-designed and managed biofloc technology systems are a viable alternative for production of various species like tilapia, to increase feed efficiency by lowering aquafeed protein requirements and to help reduce or eliminate effluent discharges.

Health & Welfare

Biofloc technology holds potential for carnivorous fish species

Juvenile carnivorous African catfish performed well in biofloc-based systems, which could help produce better quality and more disease-resistant seed of this important aquaculture species and support the expansion of African catfish farming industry.