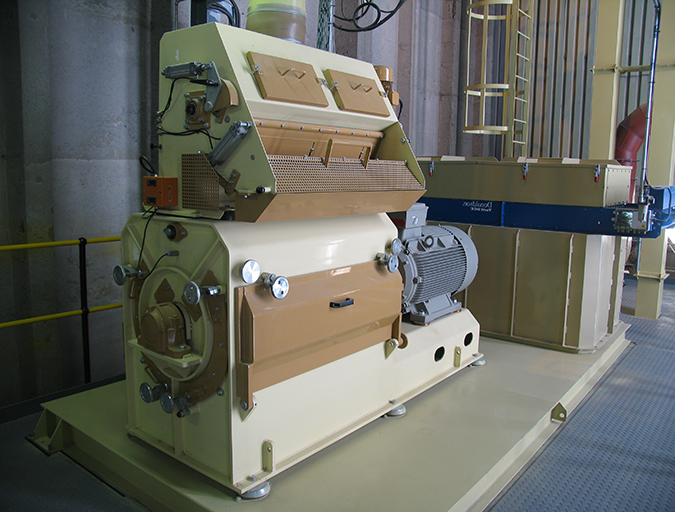

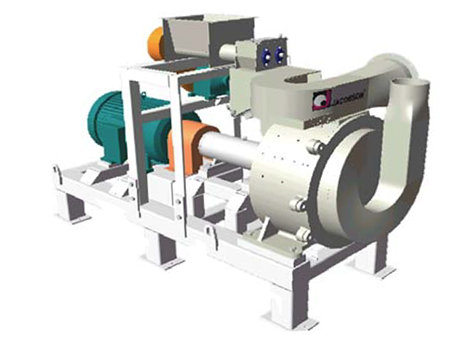

Aquafeeds

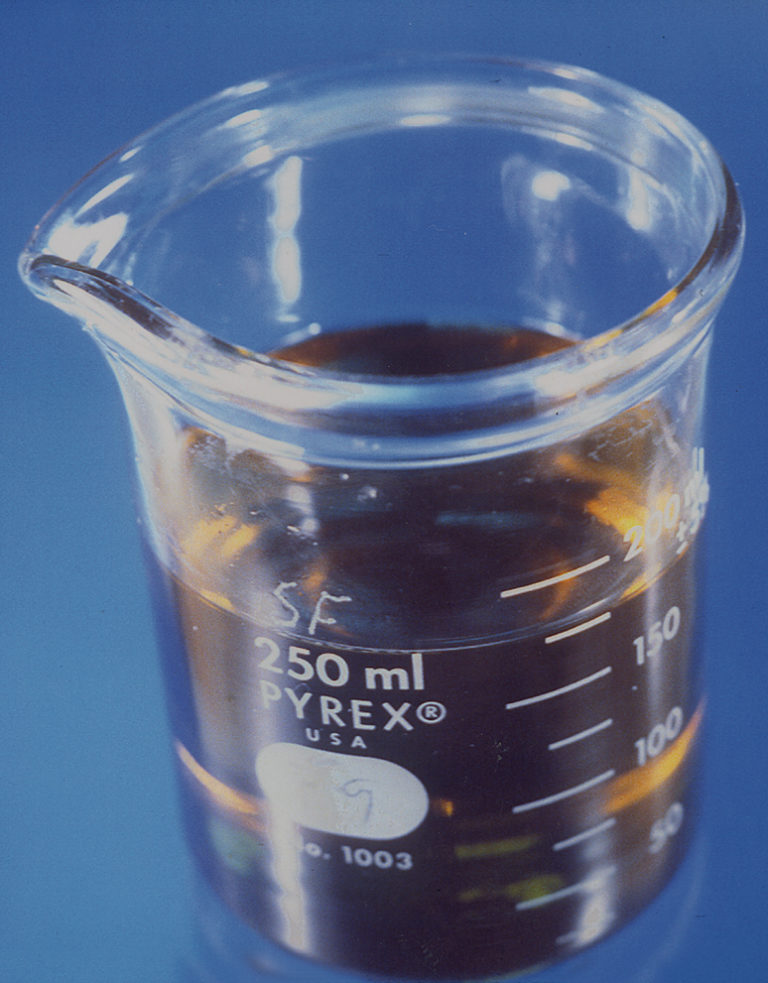

Análisis de la hidro-estabilidad de los alimentos de camarón

La integridad física y la lixiviación de nutrientes de los alimentos acuícolas para camarón son aspectos importantes en su control de calidad. La estabilidad en el agua de los alimentos de camarón se evalúa a menudo de diversas maneras subjetivas. Este procedimiento analítico proporciona una línea de base para que el fabricante de alimentos acuáticos evalúe la calidad del producto.