Controlling SME benefits production of high quality shrimp feed pellets

Extruders are more efficient than pellet presses in cooking feed ingredients through mechanical energy dissipation. The degree of cook achieved in the extruder is higher than that achieved by the pellet press. However, if too much mechanical energy is used in the extruder – even at 90 percent degree of cook – the resulting pellets may have poor water stability. In most extrusion processes, high shear has an adverse effect on the pellet water stability. This can be further understood by examining closer some important terms, including the Specific Mechanical Energy (SME), a key process parameter in extrusion processing.

Pelleting systems

Shrimp aquafeeds are traditionally manufactured using a pelleting system with long residence time pre-conditioners. The latter pre-cook the starch portion of the feed to improve its binding ability, to produce a feed with high water stability. But the process of pelleting at moisture levels close to 17 percent is more art than science. It requires highly experienced operators, and in most cases the process cannot be maintained at sustainable rates for several hours without having a stoppage. At the same time, the use of a post-conditioner has become a requirement in order to increase the degree of cook, thus improving the water stability of the feed. In the pelleting process, most of the cooking is due to the shear produced on the surface of the pellet as the meal is formed and passes through the die, and not due to the steam addition added in the pre-conditioner.

High shear and pellet hydrostability

In the feed industry there is a general understanding that a higher degree of cook meant that the water stability would also be higher. If this is so, then why has the extrusion process not become the preferred method of production of high quality shrimp feeds? Extruders do produce a higher degree of cook because the meal is preconditioned at higher moistures (> 20 percent) and because the mechanical energy applied shears the product, raising its temperature and pressure (cook) higher than a pelleting mill. Higher starch gelatinization, however, does not necessarily means higher binding capacity or higher water stability. What is called a dry extruder produces high shear, high degree of starch gelatinization (high cook), but very poor water stability. The same is true for expanders that were used to cook by shearing the meal, which was immediately pelletized. The product produced with expanders (dry extruder or high shear extruder) had poor water stability. Therefore, there is no correlation with high shear and water stability based on the experiences many people have had using high shear extruders like expanders.

Starch and cooking

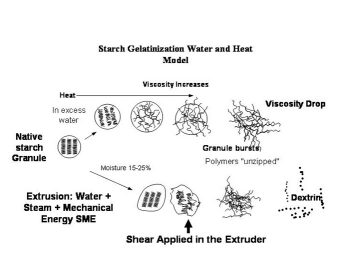

To better understand why a high degree of cook does not necessarily mean high water stability, it is first important to understand what starch is and how it is cooked in the process. Starch is a bio-polymer made of glucose units, which in its native state is arranged in a tight structure or granule. As the granule of starch is exposed to moisture and temperature, it starts to swell. As more energy is applied, the starch starts to break down.

In the pelleting process, the starch granule may swell in the preconditioner but it will not rupture. In contrast, in the extrusion process the swelling that started in the preconditioner is also accompanied by the mechanical energy input produced by the screws, the particles rubbing against each other and particles rubbing against the walls of the barrel. This additional energy causes the starch granule to rupture, followed by a decrease in the viscosity as the granule is ruptured even further by the continued action of the mechanical energy input.

As the starch or mix is worked on more, it starts behaving like a fluid known in extrusion terms as “melt.” The melt behaves like a pseudo plastic since it has similar properties to a plastic whose viscosity decreases when subjected to shear. The starch as such is then given the term of bio-polymer, as it behaves like a plastic (polymer). The term “melt” implies that the granule is not a crystalline organized structure anymore. With more energy, the starch breaks down into even smaller fractions of glucose units called dextrins (Fig. 1).

Changing physical properties

At the different stages of energy input, the starch changes its physical properties, which directly affects the physical integrity of the finished product or pellet, and most importantly, its water stability. The protein fraction in shrimp feeds also undergoes changes due to mechanical energy input. The proteins are also sheared and cooked, and become also part of the molten phase and interacts with the starch and fiber to form a matrix. As the molten extrudate passes through the die, it also experiences high shear forces. If the pressure drop is too high, the pellets may experience what is known as expansion. In the extruder prior exiting the die the pressure is high. At high pressure the water is in the liquid state, but as it leaves the die the pressure drops to atmospheric conditions (1 bar), producing a change of state from liquid to gas. This gas is vapor pressure that swells the pellet.

In shrimp feeds, the expansion needs to be controlled or the pellets produced will be of low density and float. The density of the shrimp feed is controlled by having a venting port to allow the expansion to occur, and then recompressing the expanded melt – prior to exiting the die – into distinct pellets of uniform density.

Specific Mechanical Energy (SME)

In most extrusion processes, high shear has an adverse effect on the pellet water stability. This can be further understood by examining some relevant terms. One is the Specific Mechanical Energy (SME), a key process parameter in extrusion processing. SME is the ratio of the mechanical energy input (energy derived from the drive measured in Watts) to the total mass flow rate Q. The mass flow rate is expressed in lb/hr or kg/hr then the SME is = W/Q or kj/kg, or W/kg.

The SME is used to correlate extrusion cooking conditions such as screw speed, moisture content, screw configuration, etc. to product conversion such as Water Absorption Index (WAI), and Water Solubility Index (WSI).

If the screw speed increases, the amount of SME increases (keeping feed rate constant). Changing the screw profile directly affects the SME. Screws with cut flight or reverse elements increase the shear rate and the SME. Also for the same screw speed, reducing the feed rate will increase the SME.

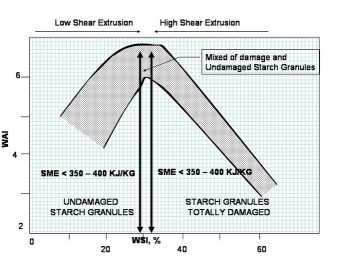

The relationship of SME to starch damage has been investigated by Smith (1992. Food Extrusion Science and Technology. Marcel Dekker Inc.). This author demonstrated a general relationship of WAI and WSI as a function of structural changes caused to the starch when it was subjected to various degrees of mechanical energy. The main parameters studied where screw configuration, moisture content and barrel temperature. Changes in these parameters caused the SME to vary from 180 to 750 kj/kg.

The data from this study also showed that the amount of swollen starch granules increased with increasing SME but the starch granules remained undamaged below 350-400 kj/kg. WAI increased as SME increased from 180 – 350 kg/kj, due to an increasing proportion of gelatinized starch granules. Similarly, the starch solubility in water increased with increasing SME due to the molecular degradation of the starch. As stated earlier, the more mechanical energy is added, the higher the starch degradation and thus the higher water solubility is. In Smith’s study, as SME increased from 500 – 550 kj/kg to 750 kj/kg, the starch granules were totally damaged, resulting in a decrease of the WAI and an increase in the WSI.

Hydrostable, extruded shrimp feeds

This last statement is important as it relates to water stability of shrimp feeds. The target is to produce shrimp feeds that can absorb water, becoming soft and pliable, but that do not break down when submerged. In reality, a shrimp can eat a softer pellet better than it can consume a hard one. When feeding, a shrimp balls up the pellet and takes it to its mouth and consumes it slowly. If the pellet is too hard, the shrimp will simply reject it and it will become wasted and potentially-polluting organic matter in the pond.

Extruders that work in the high shear region will have high SMEs, and most likely will produce pellets of poor water stability due to the high starch degradation causing it to have low WAI but high WSI. The model reported by Smith is presented in Figure 2. In the region of low SME < 300 – 400 kj/kg, it can be appreciated that the WSI increases; however, as the SME increases further (500 – 550 kj/kg), the WSI decreases while the WSI starts increasing. The latter confirms that the starch exposed to high shear or SME is degraded to the point that it becomes very soluble in water.

Perspectives

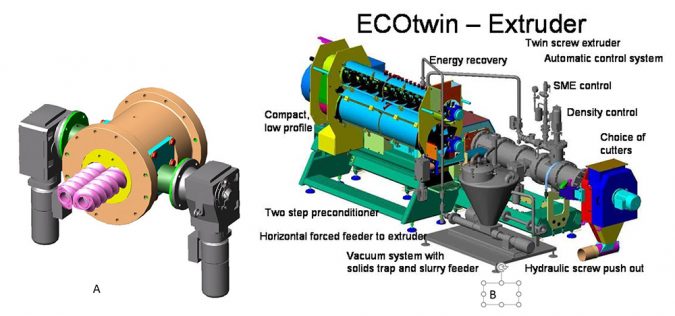

Is it then possible to produce a pellet of high water stability by controlling the SME using a standard shrimp formula with no artificial binder? The answer is yes, it can be done, because the new generation extruders are equipped with state-of-the art SME controls that permit the adjustment of the SME to the desired range, where WAI is high enough to produce a pellet that is soft and still very hydrostable (low WSI).

Author

-

Eugenio Bortone, Ph.D.,PAS, Dpl. ACAN

Sapientia Technology

Frisco, Texas USA[109,111,99,46,108,105,97,109,103,64,101,110,111,116,114,111,98,114,100]

Tagged With

Related Posts

Aquafeeds

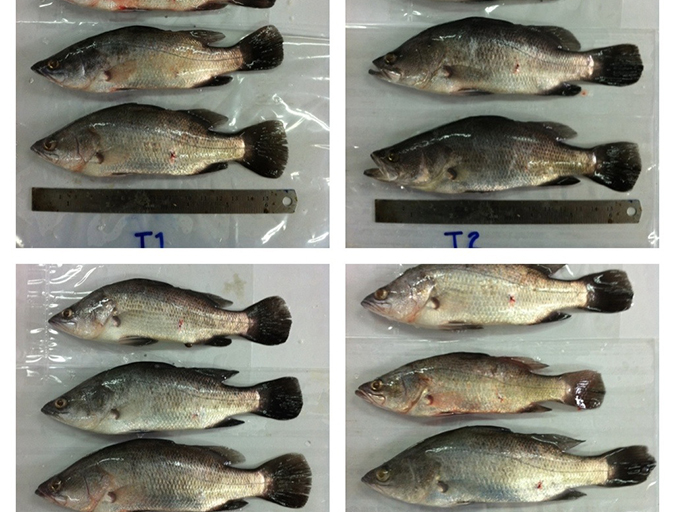

Pangasius diet trials show promise of DDGS

A feeding trial incorporated corn distillers dried grains with solubles (DDGS) as an energy and protein source in starter and grower diets for pangasius. Results showed excellent fish growth performance, and no negative effects on mortality, fillet yield or fillet color.

Aquafeeds

Improving productivity, efficiency in Asian sea bass aquaculture

The effects of the dietary acidifier and feed additive potassium diformate (KDF) were tested in diets of juvenile Asian seabass (Lates calcarifer) in Thailand. Results show that including KDF at 0.5 percent in the diets can help improve growth, survival and therefore overall production of this species.

Health & Welfare

Probiotics benefit Pacific white shrimp challenged with AHPND

A study was conducted to measure the effects of commercial probiotics on Pacific white shrimp in a standardized AHPND challenge model under controlled laboratory conditions. Results show that the probiotics treatments by themselves have beneficial effects, such as higher survival and histological signs of hepatopancreas regeneration.

Intelligence

U.S. universities collaborate on antibiotic alternative project

Two U.S. universities are teaming up to study the application of a novel antibody to tilapia to reduce the aquaculture industry’s use of antibiotics. The chairman of the Seafood Industry Research Fund says there could be a disruptive financial impact on seafood if it can’t compete in the “antibiotic-free” space.