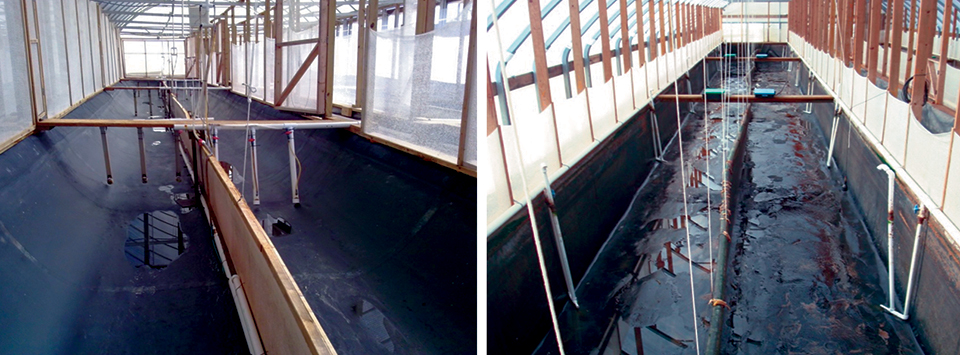

KSU research uses wastewater effluent and unused or decommissioned wastewater treatment tanks

Paddlefish (Polyodon spathula) is one of the most intriguing emerging species for aquaculture. Its ability to consume zooplankton by filter feeding, rapidly grow 2.5 to 4.0 kg per year and produce black roe for high-quality caviar has made it desirable for culture. Market surveys in the United States have demonstrated strong appeal for the caviar and boneless white meat of cultured paddlefish.

Internationally, paddlefish are also well received by consumers in Eastern European countries, including the Czech Republic, Hungary, Moldovia, Romania, Russia and Ukraine, because of the similarity of their meat and caviar to those of sturgeon. In China, whole cooked paddlefish attract consumers at high-end restaurant in large cities.

Because of this demand, more reservoirs and ponds have become available for increasing production. In 2008, about 10 metric tons (MT) of meat were produced. Production is predicted to rise to 300 to 400 MT/year by 2012, with further industry growth then expected when the next generation of breeders are available.

In the United States, the capture fishery for paddlefish is now strongly restricted, resulting in a declining supply. In Ukraine and other countries, paddlefish aquaculture has attracted a high level of public interest. In all countries, however, short supplies and high prices for seedstock are still the main factors limiting expansion of the paddlefish industry.

Research at KSU

Kentucky State University Aquaculture Research Center in Frankfort, Ky., USA, has been studying paddlefish as a food fish since the late 1980s. Initial research on phase II fingerling production was completed in ponds using a combination of zooplankton and prepared diets. However, bird predation has been a major factor in low survival. Bird netting eliminates the problem but is costly for commercial-size ponds.

Since 2006, a pilot project that uses wastewater effluent and unused or decommissioned tanks at a wastewater treatment plant has demonstrated the culture of over 70,000 phase II 200-gram paddlefish in Kentucky. Survival has increased dramatically at the plant compared to pond culture because there is no bird predation. Live zooplankton, primarily daphnids, are a first food for fry harvested from clarifier tanks. Large volumes of effluent water provide excellent water quality.

Wasterwater reuse

Wastewater treatment plants are integral parts of every urban community in the United States, as well as Eastern Europe and China. With improved methods for processing wastewater, many municipalities are building newer, larger facilities and decommissioning the old ones, many of which have tanks and ponds that could be easily and economically adapted for fish culture.

In the U.S., many older plants could be renovated as fish hatcheries and save demolition costs, increase seedstock fish supplies, create jobs and generate revenue. In most cases, new facilities are built adjacent to old and could conveniently provide treated effluent for the hatcheries, provided Environmental Protection Agency water quality criteria are followed to ensure safety for humans, wildlife and aquatic life.

Paddlefish project

The pilot project has led to a two-year research project funded by Kentucky Science and Technology Corp. and Kentucky Science and Engineering Foundation grants. Its objectives are to monitor fish growth and survival, and water quality in tanks with static or flow-through processed wastewater; to maximize public protection by biomonitoring fish grown at the facility for contaminants and to investigate the economic viability of an agribusiness based upon these technologies.

The main resources used in the study are two circular 1,125-cubic-meter digester tanks and a 135-cubic-meter sludge thickener tank that are not used in daily operations. The tanks are equipped with air diffusers and surface aeration.

Ozone-disinfected wastewater is treated under National Pollution Discharge Elimination Systems (NPDES) guidelines in adherence to the Clean Water Act of 1972. NPDES monitors wastewater treatment plants for potential toxins. Historically, the Frankfort sewer plant, which receives domestic and light industrial wastes, has data that indicates no concern for toxic compounds, but a main purpose of the project is to verify if the environment is safe and could quantitatively satisfy potential end users’ concerns.

Live Daphnid species zooplankton are the food source for phase I paddlefish up to 3.5 cm total length for the first 40 days. The zooplankton grow naturally in the four 1,500-cubic-meter clarifiers. Typically, daphnids grow well in water with high bacteria content and alkalinity and hardness above 50 mg/L.

Since daphnids are sensitive to heavy metals such as copper, high densities of daphnids associated with the wastewater would indicate good water quality. They are removed manually with plankton nets. The swimming of the daphnids disrupts the sludge blanket, causing total suspended solids to increase and often causing discharge permit violations.

The plant processes 22,500 cubic meters per day of wastewater that is disinfected with ozone and released into the Kentucky River. Using the plant’s infrastructure, processed water is supplied to the tanks and then returned to the head of the plant once more for treatment. The water is saturated with oxygen, and pH is 7.0 to 7.2. Total ammonia nitrogen values are below 1.0 mg per L, nitrite is below 0.1 mg per L, and chloride is 10.0 to 15.0 mg per L.

Consumer safety

Currently, paddlefish are being grown under control conditions to test if contaminants are detected in the tissue of the fish. Eight 2.5-meter-diameter, 2-meter-deep research tanks similar in proportion to the 13-meter-diameter commercial tanks at the facility were stocked with paddlefish fry on May 1.

Four static tanks and four with flowing effluent water will hold the fish over a four-month period until they reach phase II at a length of about 35 cm. Paddlefish samples will be collected and tested for heavy metals and organochlorine compounds. This research is essential for consumer safety.

Psychologically, the public seems to more easily accept the use of lake or river water, which can be higher in contaminants than processed wastewater effluent, for fish culture. Public perceptions of processed wastewater often center on the belief that it is contaminated with heavy metals, organochlorines and pesticides, and therefore not suitable for reuse.

However, biomonitoring is an integral part of wastewater facilities as required by law to not allow the release of problematic substances back to the environment via effluents. Hence, ongoing biomonitoring will be conducted at phase I, phase II and after one year on fish released into growout ponds and reservoirs to satisfy potential consumers.

Growing results

As a result of this project and ongoing research, several municipalities in the region have decommissioned plants that will not have to be demolished and are working on developing them into aquaculture facilities. Other species such as hybrid striped bass are being tested under similar conditions. Further, the large supply of stocker paddlefish produced have permitted over 40,000 phase II fish to be stocked in over 800 ha of water supply reservoirs in Kentucky for long-term growout of mature fish for the caviar industry.

Editor’s Note: A video production on the project entitled “Cleaning Water …Growing Fish” is available on YouTube.

(Editor’s Note: This article was originally published in the July/August 2009 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Steven D. Mims, Ph.D.

Aquaculture Research Center

103 Athletic Road

Kentucky State University

Frankfort, Kentucky 40601 USA[117,100,101,46,117,115,121,107,64,115,109,105,109,46,110,101,118,101,116,115]

Tagged With

Related Posts

Intelligence

China’s limited paddlefish culture focused on meat production

Fish farmers rear paddlefish as a substitute for bighead carp in more than 10 provinces in China. Limited supply and high fingerling prices limit expansion of production.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Responsibility

Advances in super-intensive, zero-exchange shrimp raceways

Research at the Texas AgriLife Research Mariculture Laboratory is investigating ways to improve the economic viability of super-intensive raceways for shrimp production.

Intelligence

As sturgeon farming grows, demand concerns emerge

Caviar, or lightly salted sturgeon roe, has been enjoyed for centuries as an expensive gourmet delicacy. After a drastic decline in wild sturgeon stocks, aquaculture stepped in to fill the void. But can farmed supply find lasting balance with market demand?