A review of hauling systems and holding system protocols

Nile tilapia (Oreochromis niloticus) are routinely transported 1,200 to 1,400 km from Idaho in the western United States to the live markets in the greater Vancouver area in British Columbia, Canada. Significant economic losses often occur during retail holding due to a deterioration of physical appearance that results in fish that can not be sold and mortality.

To address this problem, the authors collected information on hauling systems and protocols, water quality in hauling tanks, holding systems and management, and water quality in the retail holding systems. This project was supported by a grant from the Western Regional Aquaculture Center and the National Institute for Food and Agriculture.

Farm to store

In Idaho, tilapia are raised in raceways or circular tanks at largely owner-operated farms using artesian geothermal water. Most systems are operated in a single-pass mode, but some facilities have the ability to recirculate water to adjust temperature. The elevations of tilapia farms range from 800 to 1,600 m.

Information collected on water quality at the farms is presented in Table 1. Total ammonia nitrogen (TAN) levels ranged 0.04-1.08 mg/L, with most values less than 0.50 mg/L. The minimum dissolved-oxygen concentrations ranged 1.3-5.5 mg/L in the early morning and 2.6-6.6 mg/L in the afternoon. At three of the four farms monitored, dissolved oxygen dropped below 2.0 mg/L at night. No obvious signs of distress were observed during periods of low dissolved oxygen.

Colt, Water quality parameters, Table 1

| Parameter | Farm (Idaho) | Hauling Truck (Vancouver) | Retail Store (Vancouver) |

|---|---|---|---|

| Dissolved oxygen (mg/L) | 1.4-6.6 | 19.0-33.0 | 4.0-11.0 |

| Carbon dioxide (mg/L) | N/A | 36-80 | 0-10 |

| ∆P (mm Hg) | N/A | 13-275 | 62-48 |

| Total ammonia nitrogen (mg/L) | 0.04-1.08 | 15.0-37.0 | 0-65.0 |

| pH | 7.2-8.7 | 6.4-7.0 | 4.2-7.4 |

| Un-ionized ammonia (mg/L) | N/A | 0.018-0.088 | 0-0.541 |

| Temperature (° C) | 25-35 | 18-31 | 17-26 |

| Conductivity (mS/cm) | 0.3-1.0 | 2.0-12.0 | 0.1-12.0 |

| Alkalinity (mg/L as calcium carbonate) | 80-470 | 110-280 | 0-54 |

| Calcium (mg/L) | 6-120 | 4-65 | 5-211 |

| Magnesium (mg/L) | 0.5-40.0 | 0.6-29.0 | 2.0-51.0 |

| Potassium (mg/L) | 4-13 | 23-31 | 7-173 |

| Sodium (mg/L) | 41-63 | 311-520 | 40-1,790 |

| Heterotrophic plate counts | N/A | Over 100,000 | 4,500-100,000 |

The tilapia are transported in tanks that range from 600 to 3,000 L in size and with loading densities that range 136-225 g/L. Aeration is provided by carbon stone or ceramic plate diffusers using pure oxygen.

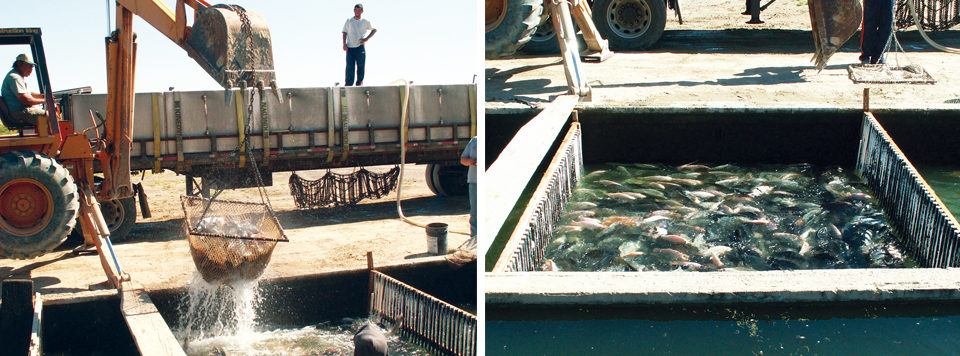

At the retail stores, the fish are netted from the distributors’ trucks into plastic laundry baskets, allowed to drain, weighed, carried into the store and dumped into the holding systems.

Depending on the store, the fish may be out of water for three to five minutes or more. Most holding systems are locally made and consist of an acrylic display tank positioned above a larger fiberglass or concrete holding tank. Water is pumped from the holding tank through a sand filter and then jetted back into the display tank. Some of the larger chain stores use commercial holding systems designed for lobsters and crabs.

After delivery, fish are added to both the display and holding tanks. As fish are sold from the display tank, they are replaced from the holding tank. Fish are not fed in the stores, and their physical appearance typically deteriorates the longer the fish are held, as indicated by loss of scales, fin and eye damage, and development of fungus.

Water quality in transport tanks

Dissolved oxygen in the hauling tanks was highly supersaturated and ranged 19-33 mg/L (Table 1). This was a result of setting the oxygen flow rate to provide enough oxygen during loading, when oxygen consumption is highest. Oxygen flows are not readjusted during the trip, even though the fish acclimate to the hauling tanks and reduce their oxygen consumption.

Carbon dioxide concentrations ranged 36-80 mg/L. The total gas pressures were undersaturated due to stripping of nitrogen and argon by oxygen, so gas bubble disease was not a problem. The TAN concentrations ranged 15-37 mg/L, and un-ionized ammonia ranged 0.018-0.088 mg/L. Over the duration of the haul, the pH dropped by 1.0 to 1.7 units.

The total heterotrophic plate counts were above the 100,000 colony-forming units/mL maximum test range. The source of these bacteria was fecal solids or regurgitation of stomach contents. The bacteria measured by this test were unlikely to have a short-term impact on the fish, but the plate counts can be used as a general measure of hauling intensity. None of the observed pH or un-ionized ammonia concentrations approached potentially lethal values.

The transfer from hauling tanks to retail holding tanks is a stressful event that occurs within five minutes. Significant changes in temperature, pH, salinity and levels of carbon dioxide and dissolved oxygen all occur at the same time. Tilapia may be able to acclimate to lower pH during hauling, but the abrupt change from the hauling tank to a low-pH retail holding system can result in significant adverse physiological and endocrinological changes.

Retail holding systems

Based on published environmental requirements, the most important water quality variables are temperature, pH and un-ionized ammonia. There was a wide variation in these variables in the retail stores.

The dissolved-oxygen and carbon dioxide concentrations were generally excellent. The typical jet aerators used in the stores provided adequate aeration and carbon dioxide removal. The average level of gas supersaturation in the stores was close to zero, and only one relatively high value was found (Table 1). The source of this gas supersaturation was air entrainment at the pump – one could clearly hear air being sucked into the pump periodically.

The ambient water temperatures in retail stores ranged 16.6 to 25.8 degrees C. Exposure to low temperatures not only affects mortality but also appears to depress the immune systems of the fish. No immediate impacts of transferring tilapia from a pH of 6.46 to 4.21 were observed within 10 to 15 minutes. In the absence of accurate store mortality information, it was impossible to determine the physiological impacts of these low pHs.

There was a wide variation in total ammonia nitrogen (0-65 mg/L), but only one case where the un-ionized ammonia concentration approached a short-term lethal concentration of 0.541 mg/L. In most cases where total ammonia nitrogen was high, the pH was low, and therefore the un-ionized ammonia concentration was also low. The accumulation of high total ammonia concentrations in retail holding systems was due to inhibition of nitrification at low pH. The largest ionic components in holding systems were sodium and chloride (Table 1).

For the low-alkalinity water in Vancouver, control of un-ionized ammonia by pH reduction is simpler and cheaper than flushing or inclusion of an effective biological filter. Effective nitrification would require higher pHs and the likely addition of sodium bicarbonate to increase alkalinity. It is unlikely that retail stores have the expertise to control the pH within the required tolerance to prevent un-ionized ammonia toxicity.

Informal management

In the authors’ review, how holding systems are operated was undocumented, as no written protocols or operational records were provided by any retailers. The level of expertise of the staff regarding fish requirements or system operations was also limited.

If all the fish were sold before the next load arrived, some stores drained and refiltered their entire systems. While this can improve the overall water quality, it could also expose fish to low water temperatures and elevated chlorine levels if fish are added too soon after refilling.

Other stores appeared not to routinely change water, but rather top off the system to replace evaporation and water spillage. The sand filters were not backwashed on a regular basis, so they probably functioned more as biological filters than as solids removal systems.

Perspectives

While potential water quality issues were identified in transport and at retail holding facilities, it was not possible to clearly identify the causes of excessive mortality. In fact, it was very difficult to relate mortality to any one supplier or hauling practice.

Most of the stores buy fish from several distributors and mix fish from different loads and distributors. For these stores, it was impossible to determine the origin of a given dead fish. In addition, retail stores would not release information on mortalities for business reasons. It was not possible to collect water quality information from retail stores on a regular basis.

Reduction of hauling impacts on product quality at the retail store is further complicated by the significant impacts of fish condition at the farm and loading methods. Because of the difficulty in conducting experiments with commercial haulers and retail stores, future work may best be conducted in simulated hauling experiments or test hauls.

(Editor’s Note: This article was originally published in the May/June 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

John Colt, Ph.D.

National Marine Fisheries Service

Northwest Fisheries Science Center

2725 Montlake Boulevard East

Seattle, Washington 98112 USA[118,111,103,46,97,97,111,110,64,116,108,111,99,46,110,104,111,106]

-

Gary Fornshell

University of Idaho Extension

Twin Falls, Idaho, USA

Tagged With

Related Posts

Health & Welfare

A look at tilapia aquaculture in Ghana

Aquaculture in Ghana has overcome its historic fits and starts and is helping to narrow the gap between domestic seafood production and consumption. Production is based on Nile tilapia.

Intelligence

Adding value to tilapia to tap into U.S. market

New markets for tilapia and expansion of existing ones can be created by planning and implementing properly designed geographic strategies to meet discriminating consumer preferences. Low labor costs in most producing countries promotes value-adding by the production of fresh fillets.

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.

Health & Welfare

Applied commercial breeding program for Nile tilapia in Egypt

A major goal of selective breeding program for Nile tilapia (Oreochromis niloticus) in Egypt is to select for fillet color and fillet weight in response to consumer preferences.