Equipment should also minimize stress on fish, shellfish

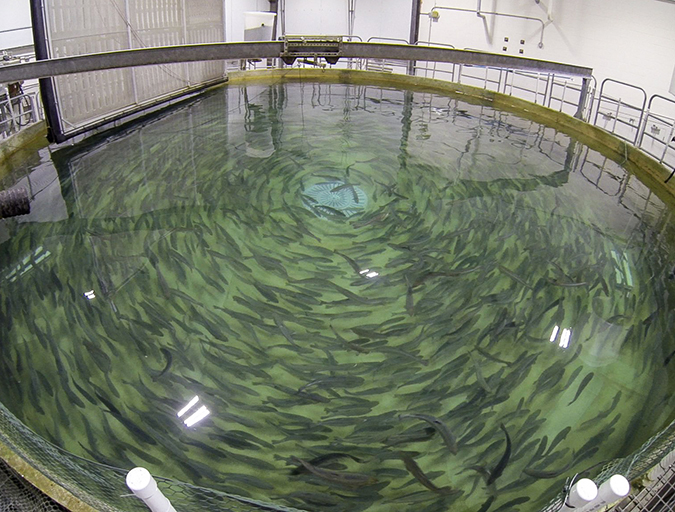

Larger and deeper circular tanks are being widely applied in aquaculture, particularly for the commercial-scale culture of trout and salmon in water-recirculating systems. The tank diameters typically range from 10 to 16 m, with sidewall depths of 3 to 6 m, particularly at farms targeting annual production levels of 400 to 1,000 mt or more.

Larger and deeper tanks can improve floor space utilization and reduce building costs. They can also reduce the cumulative fixed costs per unit of production for pumps, piping, water treatment equipment, fish feeders and dissolved-oxygen probes when compared to the use of many smaller and shallower tanks. The largest savings in variable costs realized by moving to larger tanks is likely related to a reduction in labor.

The ability to effectively and safely grade and transfer large numbers of fish is much more challenging when using large and deep circular culture tanks. The technologies and practices used to grade and harvest fish should require little labor and minimal time, and allow rapid set-up and removal. The equipment should also minimize stress on fish and not compromise worker safety.

New technologies

At The Conservation Fund Freshwater Institute, the authors have developed and evaluated in-tank crowders and top graders, as well as technologies to simplify the transfer of fish from the growout tanks to finishing/purging tanks. For example, in a comparison of the effectiveness of a purse seine and a hinged clamshell crowder to crowd fish in large tanks, the latter was found easier to control and less stressful (with lower mortalities) to salmonids.

When a slotted bar rack was used in one of the side panels of the clamshell crowder, fish were simultaneously top graded in size because the slotted panel allowed small fish to swim out of the crowder, while larger fish were crowded toward the fish transfer device. The majority of fish tended to self-sort into smaller and larger sizes within the culture tank, without lifting fish out of water.

The clamshell crowder/grader units were fabricated from polyvinyl chloride pipe fittings or marine-grade aluminum and high-density polyethylene sheets. The crowder/graders used in the 9.14-m-diameter, 150-m3 tanks weigh 75 to 150 kg when dry, so an electric winch attached to a steel beam above the tanks is used to lift the units into and out of the culture tanks. At larger farms, an I-beam is installed overhead to allow a trolley and hoist to move the crowder/graders to and from different tanks.

Crowder/grader operation

To operate, the crowder unit is lowered into the tank with the ends of both crowder panels closed and pulled tight against the tank wall to exclude fish from the relatively small area enclosed by the closed panels. The end of the first clamshell panel is tied off and held tight against the culture tank wall. The other long clamshell panel is then pulled around the tank’s perimeter to slowly crowd the fish.

When the clamshell is used for grading, the wing wall is pulled slowly in increments that can take 30 to 60 minutes, providing time for the smaller fish to swim past the grader bars. The grading process is not perfect, but the majority of smaller fish usually self-sort by swimming past the grader bars. Thus, the majority of fish that remain in the growout tank following a harvest are never handled and do not have to endure the stress of an ex situ size-sorting process.

To remove market-size fish from the culture tank, the authors tested airlift pumps and a novel sidewall harvest box. A custom 20.3-cm-diameter airlift pump was built to lift fish out of the culture tank to a dewatering and sorting box located at the top and outside edge of the tank. The airlift pumps effectively removed fish from the tank, but were not as fast and convenient as the sidewall harvest box.

Dual-drain tanks

In North America, many fish farms now use large circular culture tanks with dual drains. A sidewall harvest box was developed to take advantage of the flow discharged through a sidewall drain box, which typically receives 90 to 95 percent of the flow through the tank and is relatively free of settleable solids. To harvest fish crowded into this sidewall box, a normally vertical perforated door through the sidewall drain is opened, which allows crowded fish to rapidly flow into the sidewall drain box. A dewatering rack is also installed in the sidewall drain box to enable rapid fish harvest through the box while fish are dewatered. The fish outlet sluice channel, located opposite the sidewall box entry gate, provides a slope to its lower end.

The fish outlet sluice channel is connected to a transfer hose of 20.3- to 30.5-cm diameter, which is used to slide harvested fish to another location, such as a finishing/purging tank or palletized transfer tote. Only a small flow, typically less than 38 Lpm, is used to slide fish to finishing.

The authors have successfully used this technique to harvest rainbow trout, Arctic charr, Atlantic salmon and yellow perch. Particularly with smaller fish weighing less than 1.5 kg, tightly crowded fish generally self-transfer out of the tank and into the sidewall box.

However, to reduce stress on the fish and when transferring larger fish, such as the 4.5-kg Atlantic salmon, a large hand net is sometimes used to gently pull fish to the entrance of the sidewall harvest box. The last of the fish in the clamshell crowder also have to be netted by hand.

Clamshell grader

The clamshell grader has been applied often, sometimes with the sidewall harvest technology, at several new land-based aquafarms using recirculation in North America. To increase the distance the fish can be transferred, at least one of these commercial farms connected the sidewall harvest box to a fish pump. The farm crowds fish to the sidewall harvest box and uses a temporary cover to obscure part of the dewatering rack, which passes some water with the fish into the fish outlet sluice channel.

The outlet channel is connected to the intake of a fish pump, which pumps fish in water to finishing/purging tanks. The fish transfer water is then pumped back, or more ideally, flows by gravity back to the recirculating system after overflowing the finishing/purging system. Because accounting for water flow is critical in recirculation, the technologies to transfer fish and water from the growout to the finishing/purging system should be detailed during the design phase.

Perspectives

These fish crowding, grading and transfer technologies are helping to overcome scale-up issues and improve land-based fish farm production per unit investment. For more details, look for an open-access paper by the main author published in 2009 in Elsevier’s journal Aquacultural Engineering.

(Editor’s Note: This article was originally published in the July/August 2015 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Steven Summerfelt, Ph.D.

The Conservation Fund Freshwater Institute

1098 Turner Road

Shepherdstown, West Virginia 25443-4228 USA[103,114,111,46,101,116,117,116,105,116,115,110,105,114,101,116,97,119,104,115,101,114,102,64,116,108,101,102,114,101,109,109,117,115,46,115]

-

John Davidson, M.S.

The Conservation Fund Freshwater Institute

-

Travis May

The Conservation Fund Freshwater Institute

-

Curtis Crouse

The Conservation Fund Freshwater Institute

-

Thomas Waldrop

The Conservation Fund Freshwater Institute

Tagged With

Related Posts

Innovation & Investment

Getting proficient in RAS fundamentals

A number of large salmon farming companies are now investing significantly to increase land-based, water recirculating aquaculture systems (RAS) in northern Europe and North America, and there is likely a need for more trained farm personnel to run and manage these and other close-containment aquaculture facilities.

Intelligence

An inside look at Sino Agro Foods’ giant prawn MegaFarm

Sino Agro Foods has developed a proprietary recirculating aquaculture system that yields high production volumes and profitability. The facility should significantly contribute to seafood production in China and to help satisfy increasing demand for high value, safe and sustainably produced seafood.

Innovation & Investment

Competitiveness comes at scale for RAS operations

Total RAS salmon production worldwide is less than half of 1 percent of total production. Many of the investors flocking to the sector now are new to fish farming, and confident in its potential.

Innovation & Investment

Stormborn: The U.S. land-based shrimp farming industry

With farmed shrimp production having largely shifted overseas, RAS technologies offer potential solutions for growing production in the United States. The industry is poised for growth, thanks to entrepreneurs who believe in its potential.