California’s Moleaer snags $9 million in funding to expand work in aquaculture

Nanobubble technology is fast emerging as a star performer for aquaculture, improving water quality, reducing energy costs and increasing fish biomass considerably compared to existing methods of oxygenation.

In a firm nod of approval of its potential, one company, Carson, Calif.-based Moleaer, recently secured (U.S.) $9 million in funding, the largest investment to date in nanobubble technology. The series B funding raise was led by S2G Ventures’ Oceans and Seafood Fund and joined by existing investors, ADM Capital’s Cibus Enterprise Fund and Energy Innovation Capital.

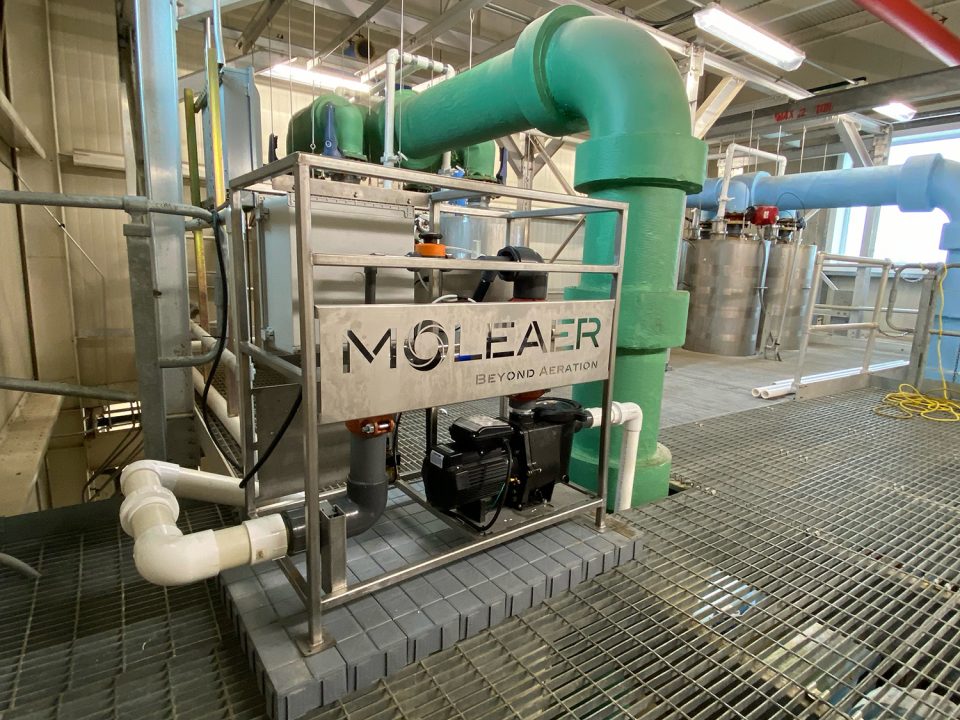

Moleaer entered the marketplace five years ago with a gas-to-liquid injection system. Gas is injected through a nanobubble generator and dissolved with super efficiency, producing nano-sized bubbles that remain suspended in the water for long periods of time.

“They act like a battery that delivers oxygen continuously to the entire body of water,” said Nick Dyner, CEO at Moleaer. The nanobubbles remain stable in liquid until they interact with surfaces or contaminants and transfer oxygen to the liquid until they collapse. In this way, they are superior to all other scalable gas transfer methods, Dyner said.

Moleaer has more than 1,000 installations and is treating water in agriculture, surface water and natural resources. The company entered the aquaculture arena just 18 months ago and counts salmon and shrimp farmers among its customers. Its system has had broad appeal thanks to its easy adoption and plug-and-play installation. The generators can be purchased or rented; the rental system includes monitoring dashboards and equipment so that aquaculture customers have proof the technology is functioning optimally.

https://www.aquaculturealliance.org/advocate/jala-engineering-innovation-indonesian-shrimp-farmers/

“There’s an optimal level of oxygenation that fish farmers want to achieve, and we’re achieving those saturation points more effectively than anyone else can,” Dyner said. Customers are making their money back on their investment within six to 18 months, he added, primarily in oxygen savings.

“Our technology provides more than 85 percent oxygen transfer efficiency, the highest proven oxygen transfer rate in the aeration and gas-to-liquid transfer industry. By contrast, typical systems provide between 1 and 3 percent. This high oxygen transfer rate means a farmer could significantly reduce the amount of oxygen they need to purchase. Our aquaculture customers are also seeing improvements in fish health and growth rates, better feed conversion ratios, significantly improved water quality and more effective removal of sea lice.”

While there are other ways to make nanobubbles, Dyner said Moleaer’s technology is unique in that it can be sized and scaled to any application. “We can tolerate any water quality, from wastewater and sludges to lake water, and our system is the most cost-effective and easiest install and deploy,” he said.

Aquaculture constitutes 20 percent of Moleaer’s business to date and the segment is growing rapidly. One of the company’s salmon farmers noted a 22 percent increase in fish biomass after deploying nanobubble technology.

Trials in Canada

Grieg Seafood began a trial of Moleaer’s nanobubble technology in September 2020, comparing it to a tank of similar size operating with its traditional pressurized air systems. Mike Anderson, projects technical manager, said the company will start deploying Moleaer’s system by the end of the summer at its new 400-metric-ton recirculating aquaculture system (RAS) facility in Gold River, British Columbia.

“We found it was a much easier system to operate, more efficient and that it was easier to maintain oxygen levels in tanks using nanobubble technology,” he said. “In both tanks, the fish reacted similarly during the one-month trial, but over a longer period we’re hoping to see improvements in fish health and growth rate.”

The price of the new system compared to the powdered activated carbon (PAC) system was also comparable, though the company expects the nanobubble technology will lower its operating costs. “The most important reason we’re switching from the PAC system to nanobubble technology is that it allows us to remove a pressurized cylinder that has a large footprint, and certification and maintenance requirements from Technical Safety BC,” he said. “Moleaer’s system is safer to operate and doesn’t have those requirements.”

Dyner said Moleaer will use the $9 million investment to continue expanding its presence in aquaculture, but one species at a time, starting with markets it can easily access.

“As we get salmon and shrimp under our belt, we’ll look at trout hatcheries, and later, the shrimp market in Asia,” he said. “As we bring nanobubbles to specific markets, we have to bring a strong understanding of why the bubbles create that value, so we can meet new applications in aquaculture.”

The company is also examining nanobubble technology’s ability to remediate sea beds by removing Beggiatoa, a genus of bacteria.

“Beggiatoa grows in eutrophic conditions on the seafloor when fish farms release too many nutrients into the environment, and Moleaer nanobubbles can deliver effective habitat remediation to reduce the environmental harm of some forms of aquaculture,” Dyner said. “It’s the same process we use to treat lakes where excess nutrients increase the oxygen demand, consuming all the oxygen in a waterbody and ‘killing’ the pond/lake/region of the ocean.”

This is the fifth investment for S2G Ventures’ Oceans and Seafood Fund, which launched last year and has dedicated $100 million to invest throughout the ocean and seafood supply chain and in marine resources.

“Our portfolio companies are using nanobubble technology in controlled indoor and outdoor agriculture, and the technology has been around for quite some time – but Moleaer was the first to commercialize it,” said Larsen Mettler, managing director at S2G.

“We saw the potential for Moleaer to pursue additional avenues and enter new markets they’ve not entered yet because historically they focused on wastewater, gas and agriculture. We see potential in aquaculture and food processing, and we have the means to enter those markets and be successful.”

Mettler said S2G aspires to add significant value beyond capital to the companies it invests in and often takes a board seat or becomes an advisor to those companies. He will serve on Moleaer’s board, where he plans to help the company establish strategies to enter different markets in aquaculture and come up with new ways to utilize its technology in seafood and ocean ecosystem regeneration.

“Our goal would be to have Moleaer recognized within a year as the most efficient, sustainable way to provide dissolved oxygen levels in open aquaculture, RAS and hatchery systems,” he said. “I think we will have expanded beyond salmon and shrimp in a year too, as this has potential across any species being farmed. We believe we have the relationships and knowledge to make those introductions and structure profitable businesses. We think this is a unique platform technology that has so many applications, and we’re really excited to be a part of it.”

Mettler added that S2G believes there’s potential for another round of funding for Moleaer and is reserving another $5 to $10 million towards that second round.

Also on the bubble

Moleaer is not the only company producing nanobubble technology. In Colombia, Win2Sol Holdings has been in the field for the past decade, applying its technology in aquaculture and agriculture.

“We create an electromagnetic field that ionizes the water particle and transfers the gas,” said Juan Gutierrez, CEO. “There’s great potential to save money and energy but it hasn’t gone mainstream yet and there aren’t many companies using it.”

Over the past 10 years, he’s sold 80 nanobubble technology units and has applied the technology to barramundi, trout and shrimp farms with great results. Gutierrez recently purchased Emerald Trout in Bogota and will be applying nanobubble technology on this trout farm as he expands it.

“Each unit is a plug-and-play, easy-to-install diffuser that saturates and disinfects the water, and reduces the need for antibiotics,” he said. “It hyper-saturates the water to the point where you have stable oxygenation for the fish. It also reduces your energy impacts by a 1:5 efficiency ratio, compared to an oxygenation cone.”

Win2Sol has two models that sell for $18,000 and $29,000 respectively, and a manufacturing partner in Japan that could turn out 40 units each month. But the biggest challenge to the company’s growth has been changing mindsets.

“People are focused on the traditional system and it’s hard to change their mind because the technology is still relatively unknown,” he said. “We’ve sold to universities and production facilities that want to deviate from traditional oxygenation systems. Now we’re applying it to our own farm at Emerald Trout, to demonstrate the technology’s efficiency. Once we demonstrate the improvements on our own farm, we hope to invite others to see what we’re doing.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lauren Kramer

Vancouver-based correspondent Lauren Kramer has written about the seafood industry for the past 15 years.